Big Bags, Containers, Bunkers, Silos and other Storage Systems

Storing + Dosing

AZO® Big Bag Discharge Station

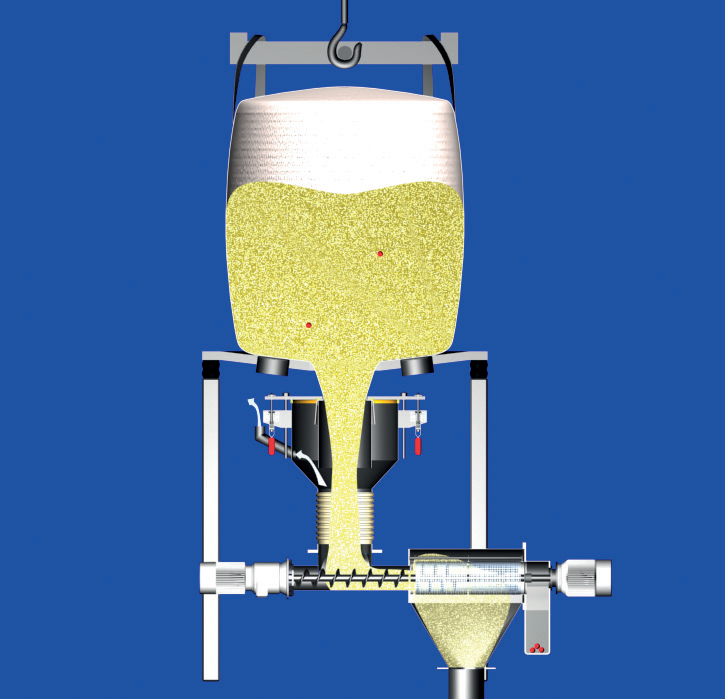

The AZO® Big Bag Discharge Station is designed for the efficient and low-dust discharge of bulk materials, offering reliable handling for materials stored in big bags. This station is compatible with big bags featuring inner liners and includes options for a liner tautness device to ensure secure handling. It is equipped with a vibrator or bag massager for difficult-to-discharge materials and optional low-level indicators to signal when a bag change is required. The system is an environmentally friendly solution for shipping and handling, aligning with modern sustainability practices.

The operation involves suspending the big bag from a frame attached to a hoist, placing it on the support table, and connecting the discharge sleeve to the downstream process via a clamping disc. Pneumatically lowering the clamping disc secures the sleeve, and the drawstring is released to allow discharge. The modular design accommodates various bag sizes up to 1200×1200 mm and integrates seamlessly into automated feeding systems. Constructed from epoxy-coated or stainless steel, the station meets industrial hygiene and durability standards, making it ideal for diverse applications in automated and closed systems.

AZO® DOSITAINER®

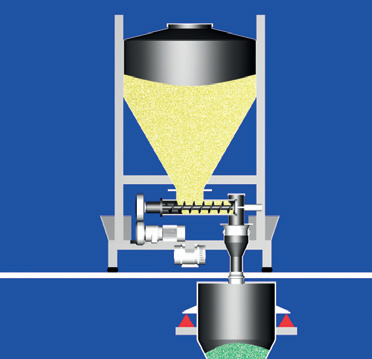

The AZO® DOSITAINER® with discharge base is a versatile container system designed for precise dosing and efficient handling of bulk materials. Featuring an integral dosing screw, it enables residue-free switching between materials without interim cleaning, making it ideal for automated conveying and weighing processes. The system ensures precise metering with frequency-controlled coarse and fine dosing, supported by a pneumatically operated seal to prevent material leakage. Its patented docking collar minimises dust generation during discharge, making it suitable for hygienic and low-contamination operations. An optional vibrating discharge aid enhances reliability for difficult-to-discharge materials, while identification systems help prevent container mix-ups and ensure batch traceability.

The DOSITAINER® is suitable for applications involving ignitable and highly flammable dusts, with design options accommodating minimum ignition energy (MIE) levels between 1mJ and ≥3mJ. It serves as a portable storage bin or transport container with capacities ranging from 650 to 2000 litres. Constructed with chromium-nickel steel in areas contacting products, it offers excellent durability and hygiene. Additional features include air injection points for outlet cleaning and stackable designs for optimised storage and handling. The discharge base is equipped with a permanently installed drive and supports easy integration into automated systems, providing precise and efficient bulk material handling solutions

AZO® BATCHTAINER®

The AZO® BATCHTAINER® is a versatile and efficient system designed for the automated handling of bulk materials in production processes. It is particularly suited for materials with poor flow properties and provides dust-free discharge and seamless batch tracking. The system’s rugged, easy-to-clean design allows for fast and flexible product changeovers, making it ideal for industries requiring accurate batch documentation and traceability. The BATCHTAINER® integrates seamlessly into automated processes, functioning as a transportable storage container that can be docked and locked pneumatically, eliminating the risk of identification errors through its electronic ID system and patented docking sleeve.

Constructed from 304 stainless steel, the BATCHTAINER® offers various outlet cone angles (48°, 62°, 78°, and 90°) to accommodate materials with different flow properties. It features stackable, forklift-compatible designs with capacities ranging from 1,000 to 2,000 litres. Options include standard corrosion-resistant or sanitary-grade finishes to suit varying application demands. The system is designed for efficient integration into warehouse and production environments, allowing for bulk material handling with high hygiene standards and minimal contamination risks.

ARP® BUNKERS

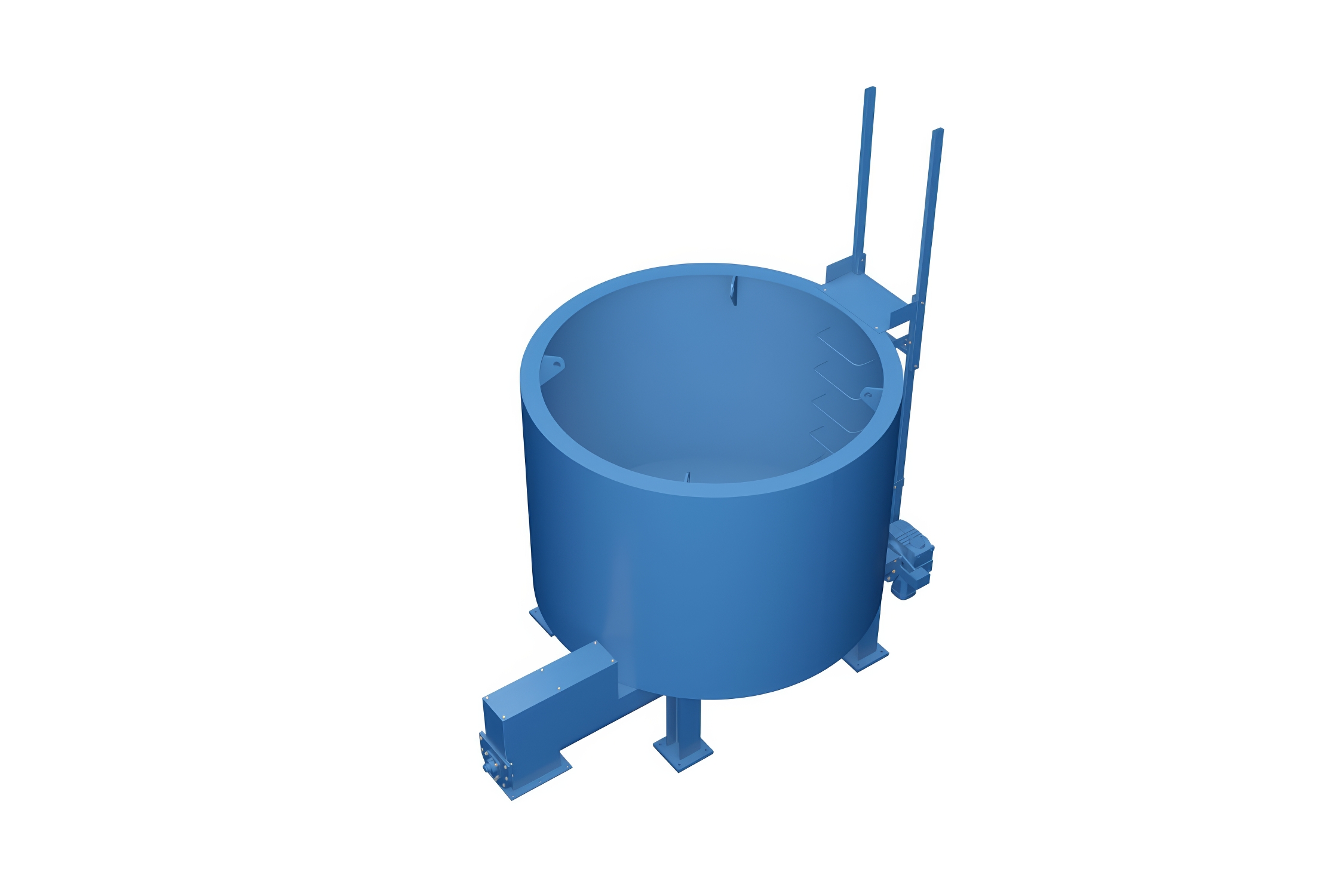

ARP offers tailored storage solutions to meet diverse processing requirements, including the Chip Bunker 6 m³ and the Container Bunker 18 m³. The Chip Bunker 6 m³ is designed for efficient storage and handling of metal chips, featuring a raker with a 0.75 kW drive and worm conveyors available in two capacities: 500 kg/h with a 0.55 kW drive and 1,000 kg/h with a 0.75 kW drive. The unit’s empty weight is approximately 2,800 kg, and its dimensions are 3,160 mm in length, 2,700 mm in width, and 3,700 mm in height. It accommodates a feed height of at least 2,400 mm and a maximum opening diameter of 2,100 mm, facilitating the efficient collection and processing of metal chips.

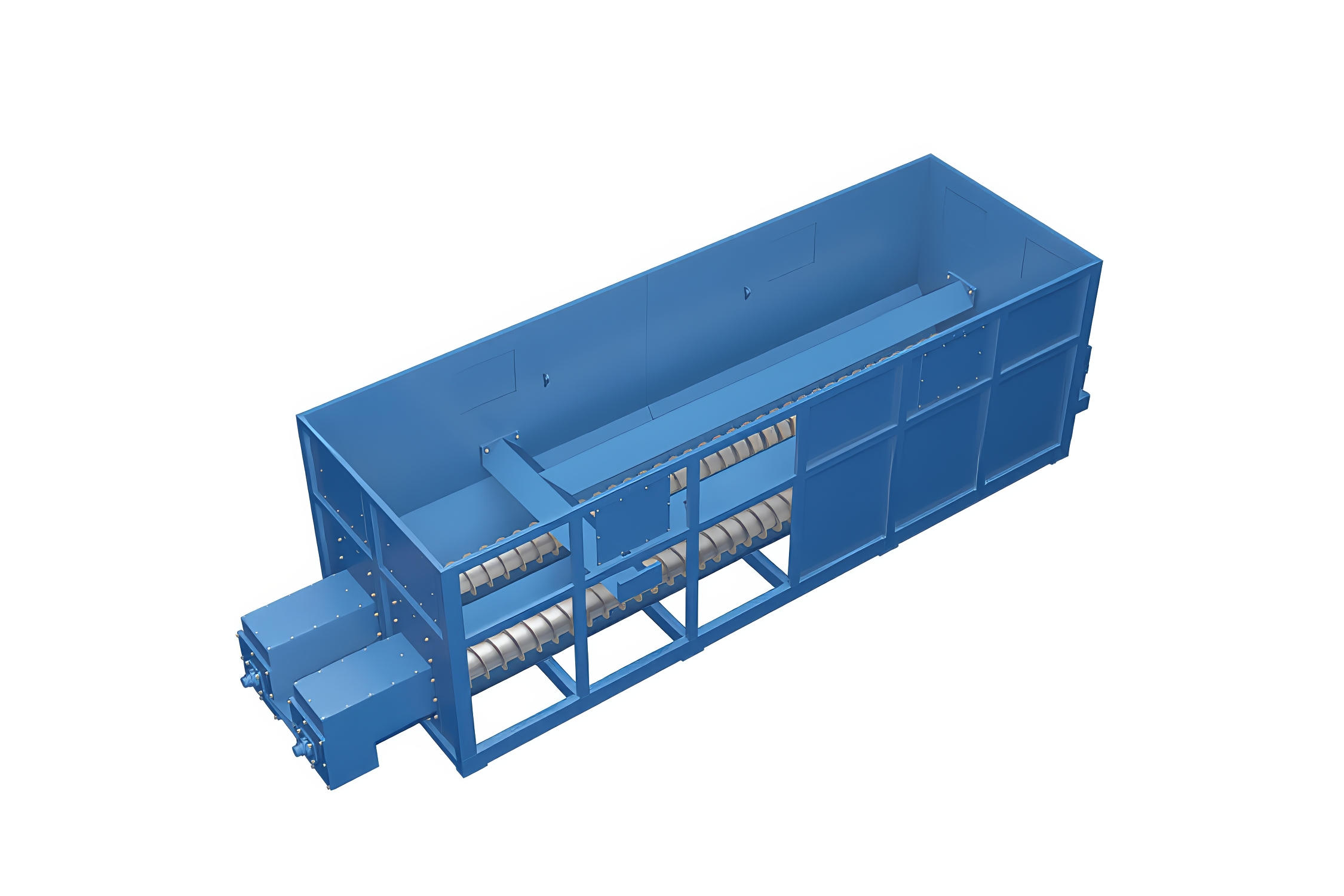

For larger storage needs, the Container Bunker 18 m³ provides a substantial capacity with dimensions of 7,400 mm in length, 2,000 mm in width, and 2,000 mm in height, which is extendable to suit specific requirements. It is equipped with dual worm conveyors, each powered by a 4 kW drive, ensuring efficient material handling. The unit’s weight is approximately 4,050 kg, reflecting its robust construction designed to handle significant volumes of material. Both storage solutions are engineered to integrate seamlessly into processing lines, offering flexibility and efficiency in material management.

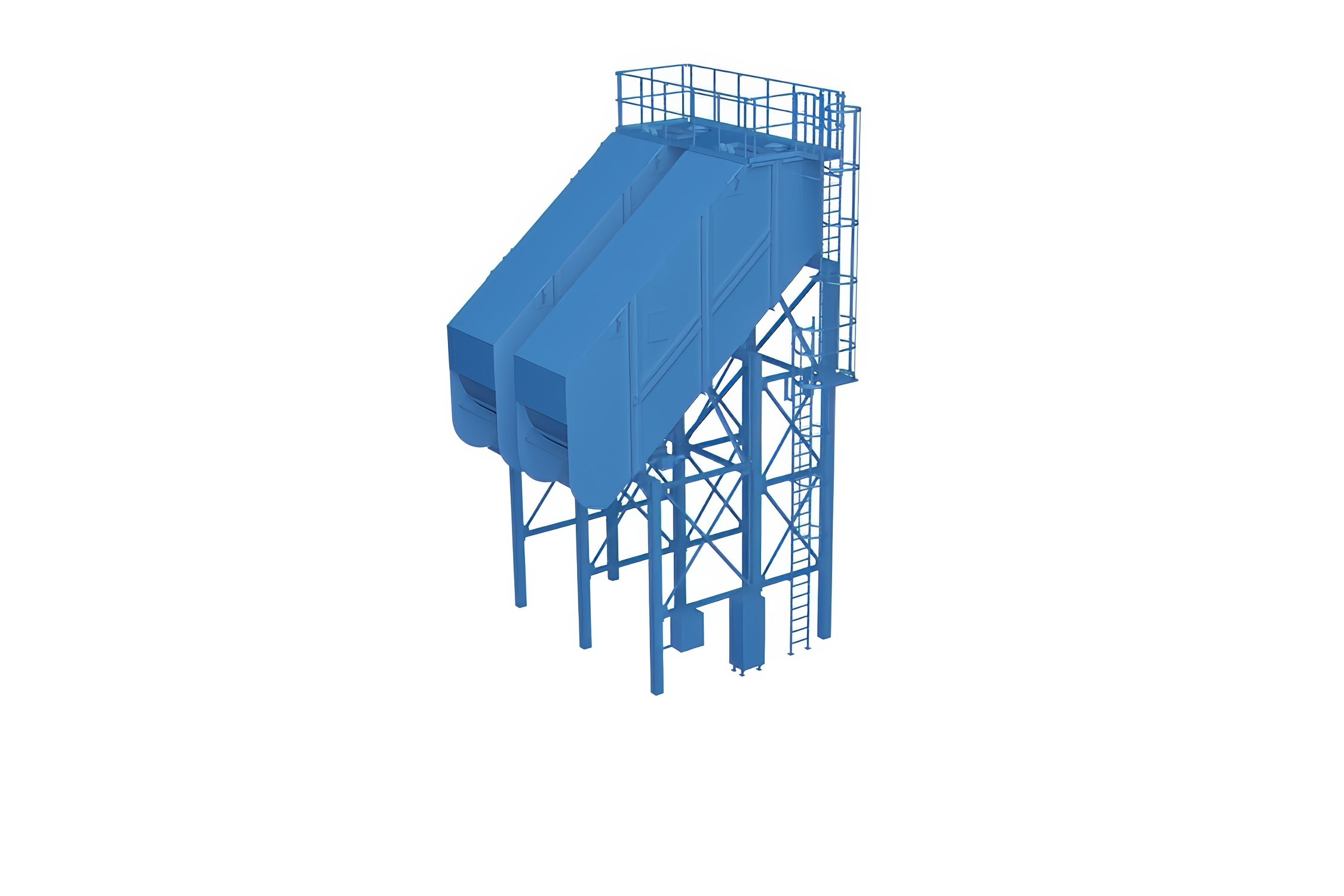

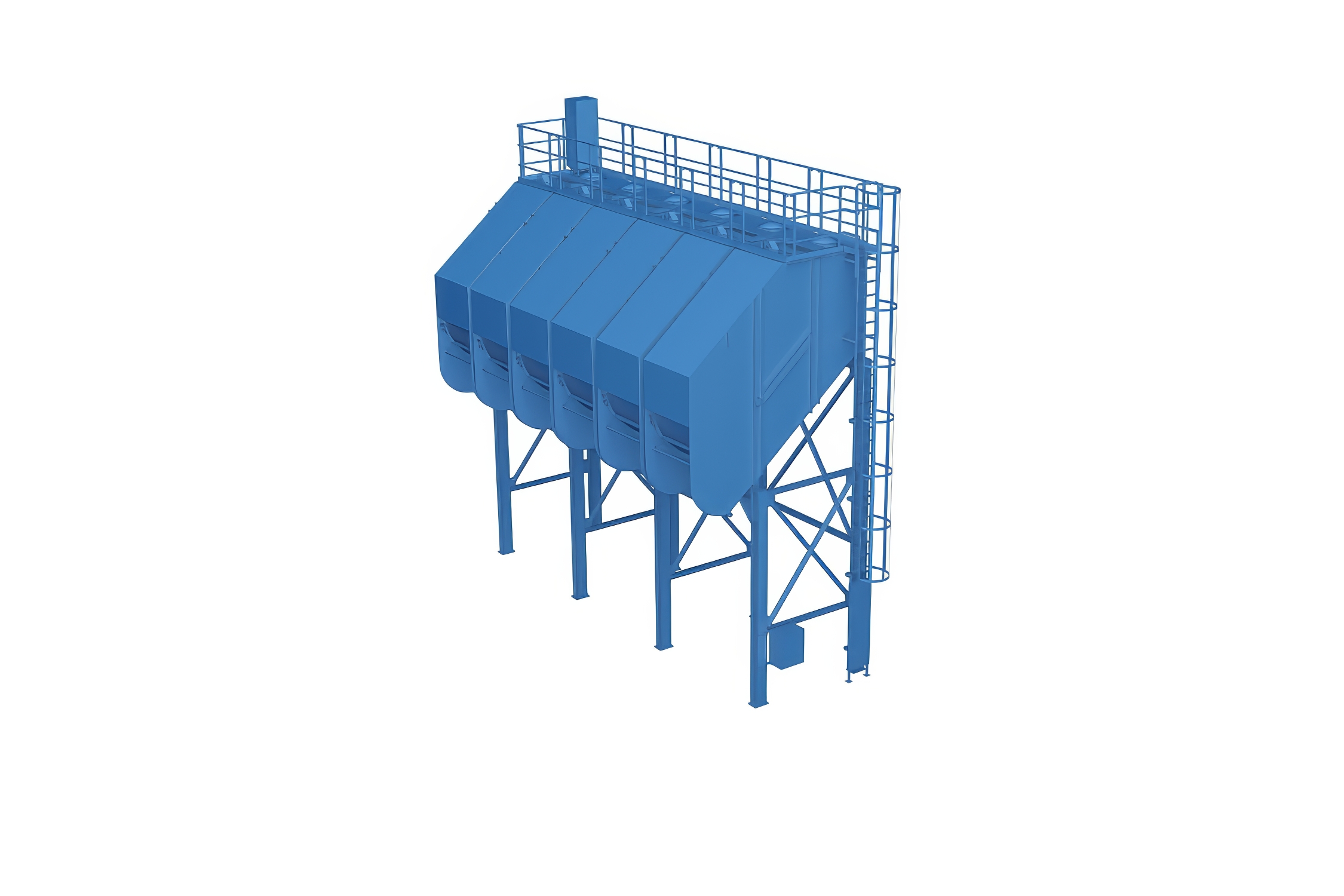

ARP® SILOS

ARP provides versatile storage solutions tailored to diverse processing requirements, including the Silo System 10 m³ and the Silo System 25 m³. The Silo System 10 m³ features a modular design with customizable chamber configurations, each offering a volume of 10 m³ and a filling capacity of up to 20,000 kg per chamber. This flexibility allows for efficient storage and handling of various materials, accommodating specific operational needs. Additional options are available upon request to further tailor the system to particular applications.

For larger storage capacities, the Silo System 25 m³ offers similar adaptability, with chambers designed to hold 25 m³ each and a filling weight capacity of 18,000 kg per chamber. This system is suitable for operations requiring substantial storage volumes and can be configured with any number of chambers to meet specific processing demands. As with the 10 m³ system, additional options can be provided to customize the setup according to particular requirements.

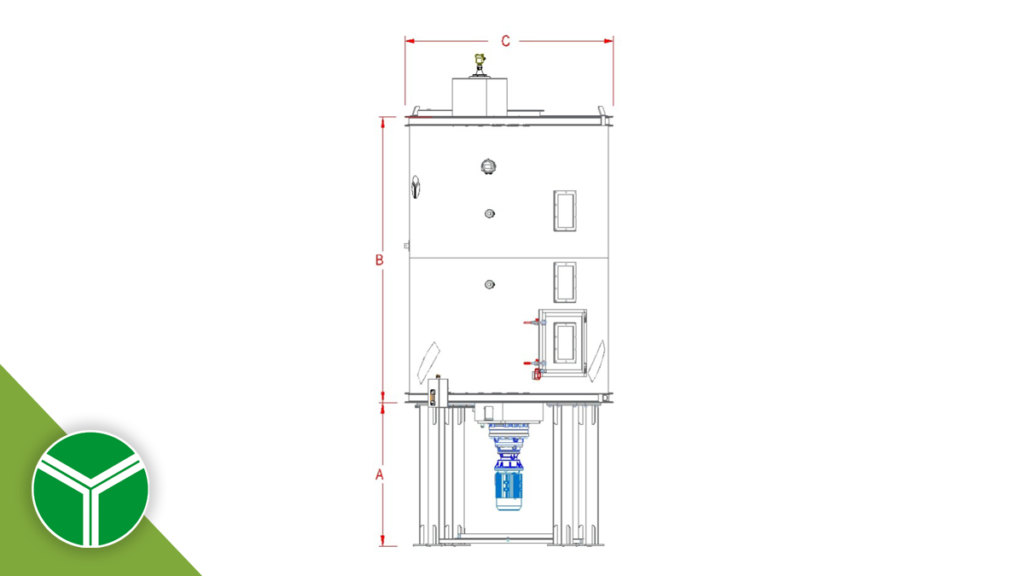

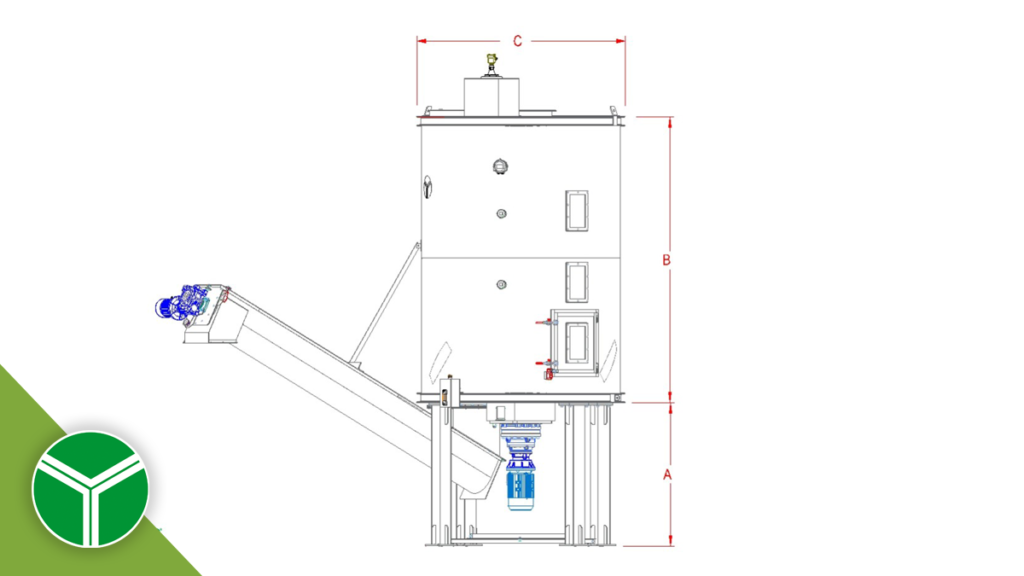

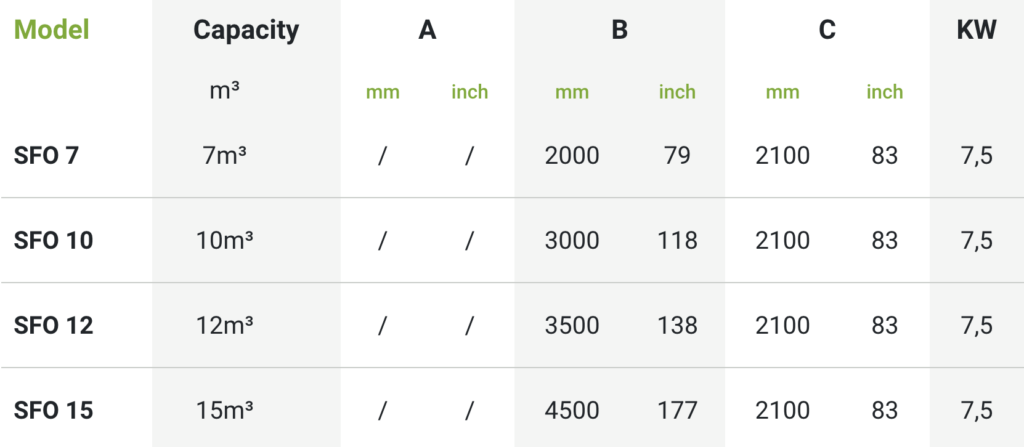

TECNOFER® FILM STORAGE SILOS

Drawing | Dimensions & Capacities

O.M.A.R.® SILOS

OMAR provides circular metal silos composed of flanged and bolted elements for storing solid materials in powder or granule form, equipped with legally compliant control and safety devices.

Depending on requirements and applications, they can be custom-manufactured from painted black sheet metal or galvanized sheet metal.