Dual-Shaft Shredding Machines

SHREDDERS

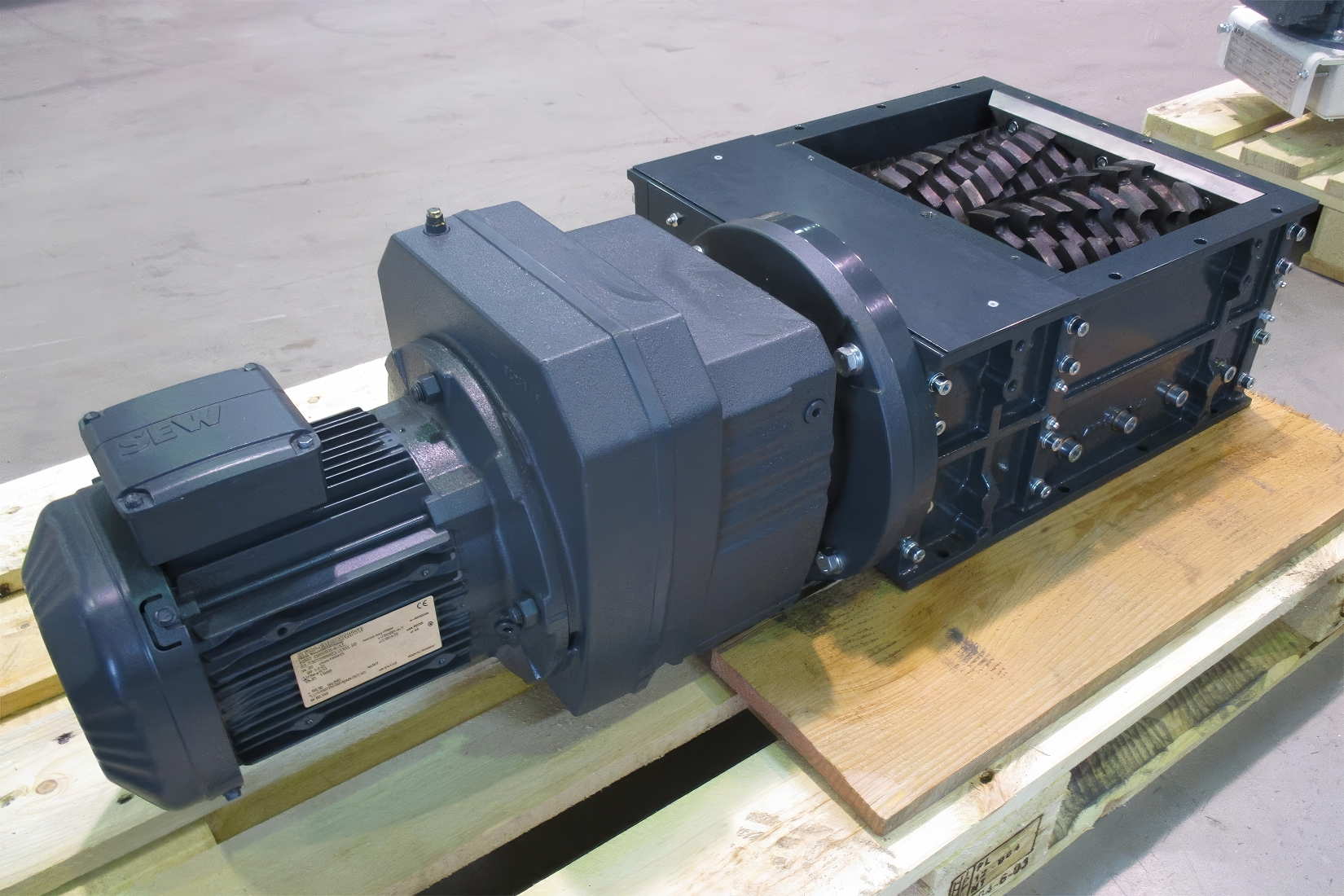

Dual Shaft Shredding Machines – ITR TSS

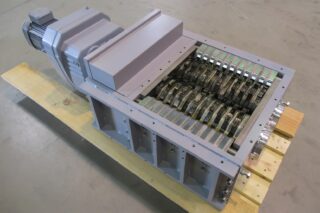

ITR Recycling Technology’s TSS dual-shaft shredders are engineered for volumetric reduction and rough material processing, preparing waste for further recovery and separation stages.

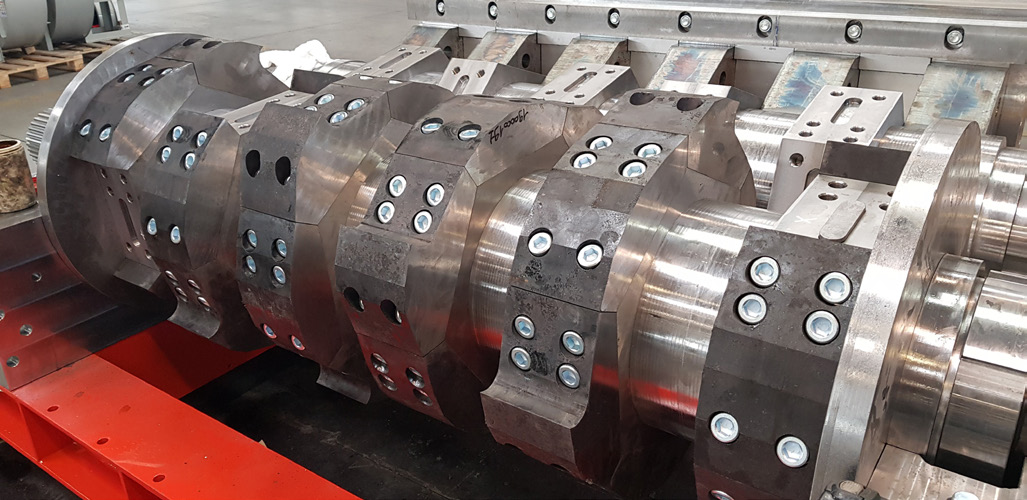

These shredders are equipped with a cutting chamber designed for easy maintenance, enabling quick replacement of wear components such as blades, spacers, and counter-blades, minimising operating costs and downtime.

With configurable blade setups tailored to different material types, TSS shredders offer exceptional versatility, making them suitable for a wide range of production applications.

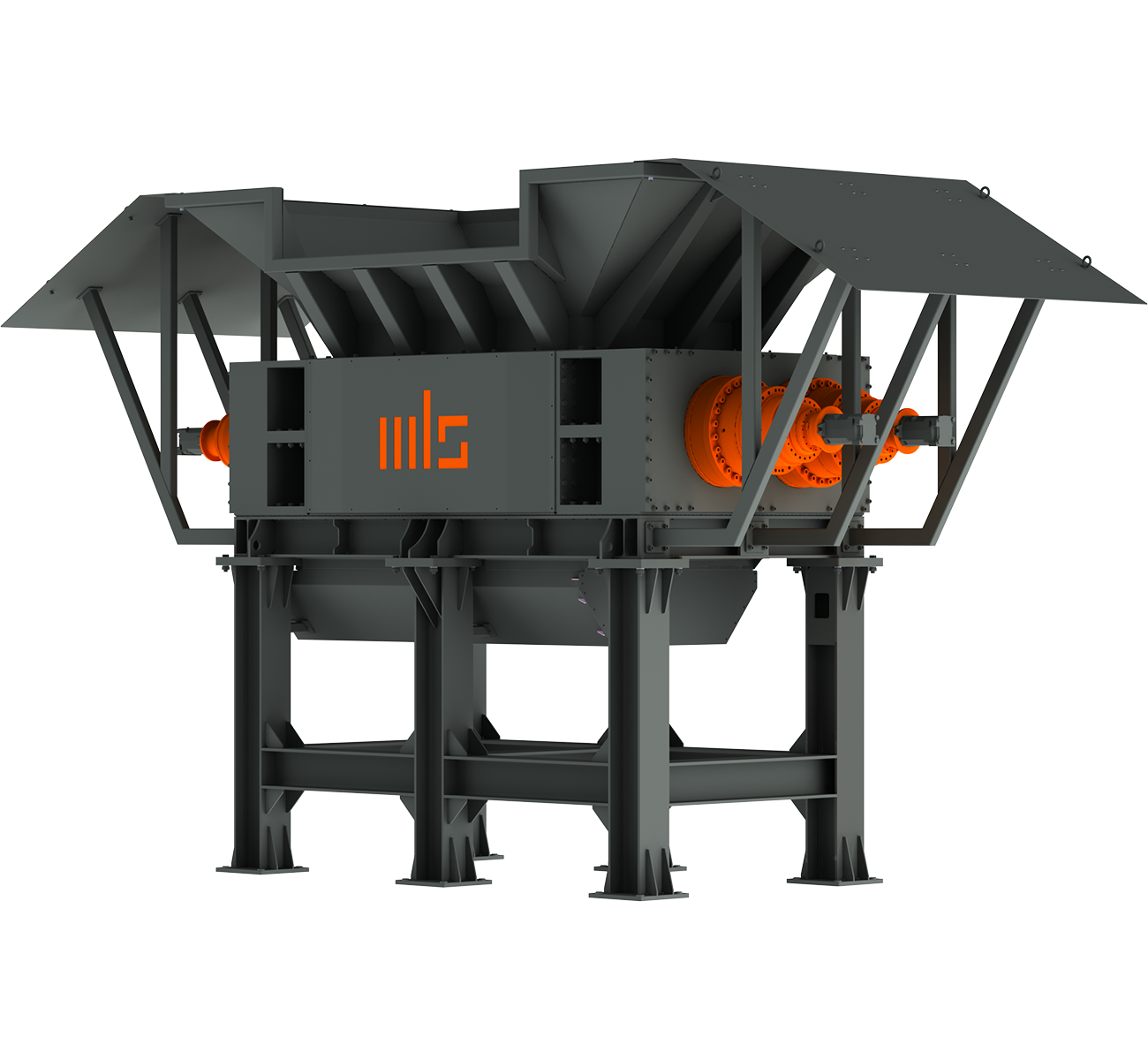

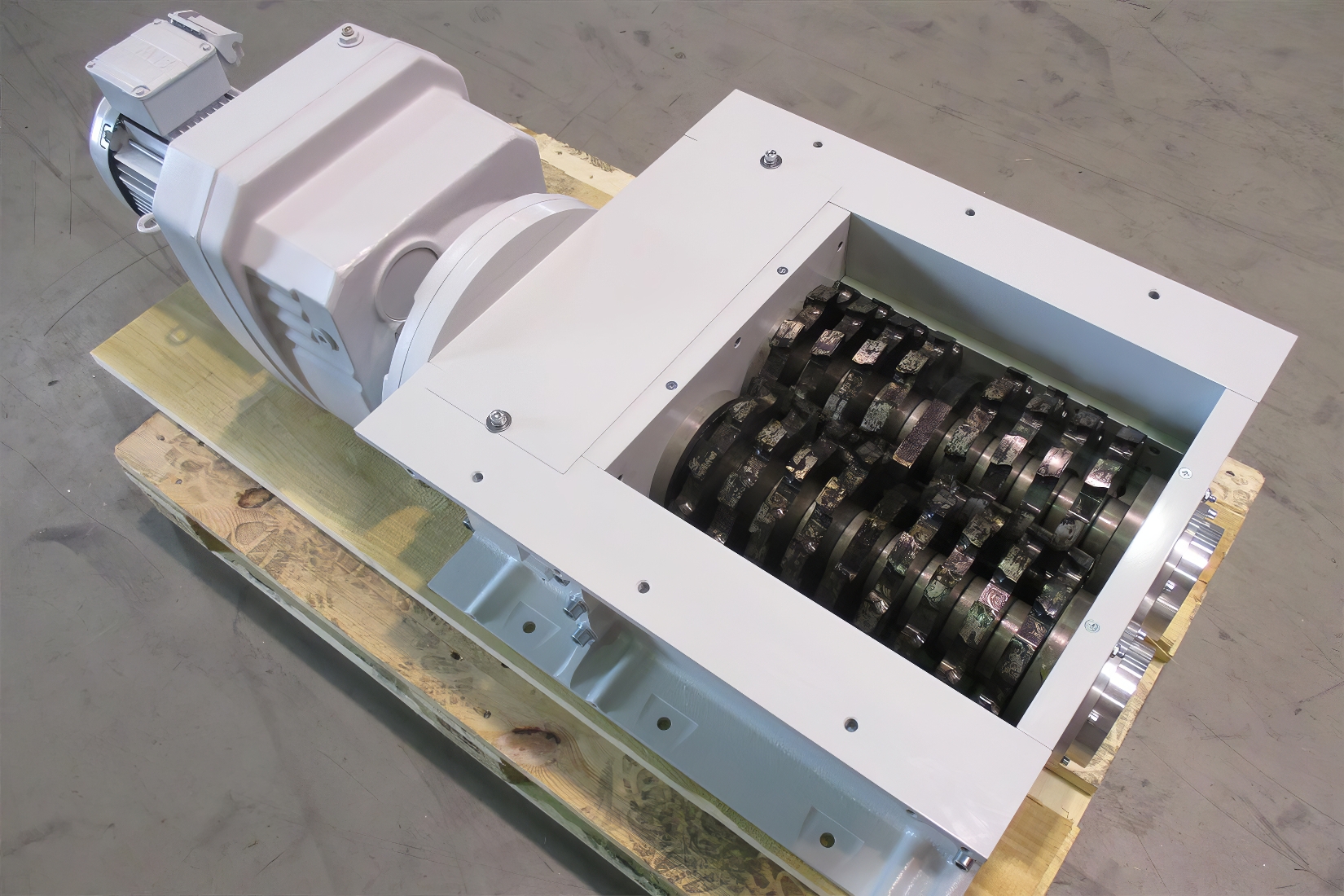

Dual Shaft Shredding Machines – MLS Makina

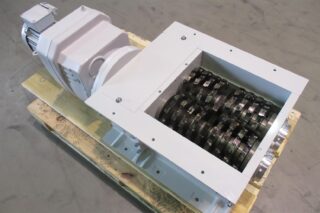

The two-shaft shredder from MLS Makina, represented by Hard Recycle in Australia, is a forward-thinking solution tailored for the recycling industry’s future. This versatile machine is adept at processing metals like aluminum but is also effective with hard plastics and other materials, allowing for the separation of various components from scrap. With its dual rotors and movable blades, it efficiently reduces materials into smaller pieces, enhancing recycling processes. The design includes easily replaceable blades, ensuring straightforward maintenance and operation. This shredder is a significant leap forward in improving waste management and recycling efficiency. At Hard Recycle, we are proud to offer this critical equipment to the Australian market as part of our dedication to a sustainable future. We’re excited to showcase our contribution to recycling, advancing towards a cleaner tomorrow.

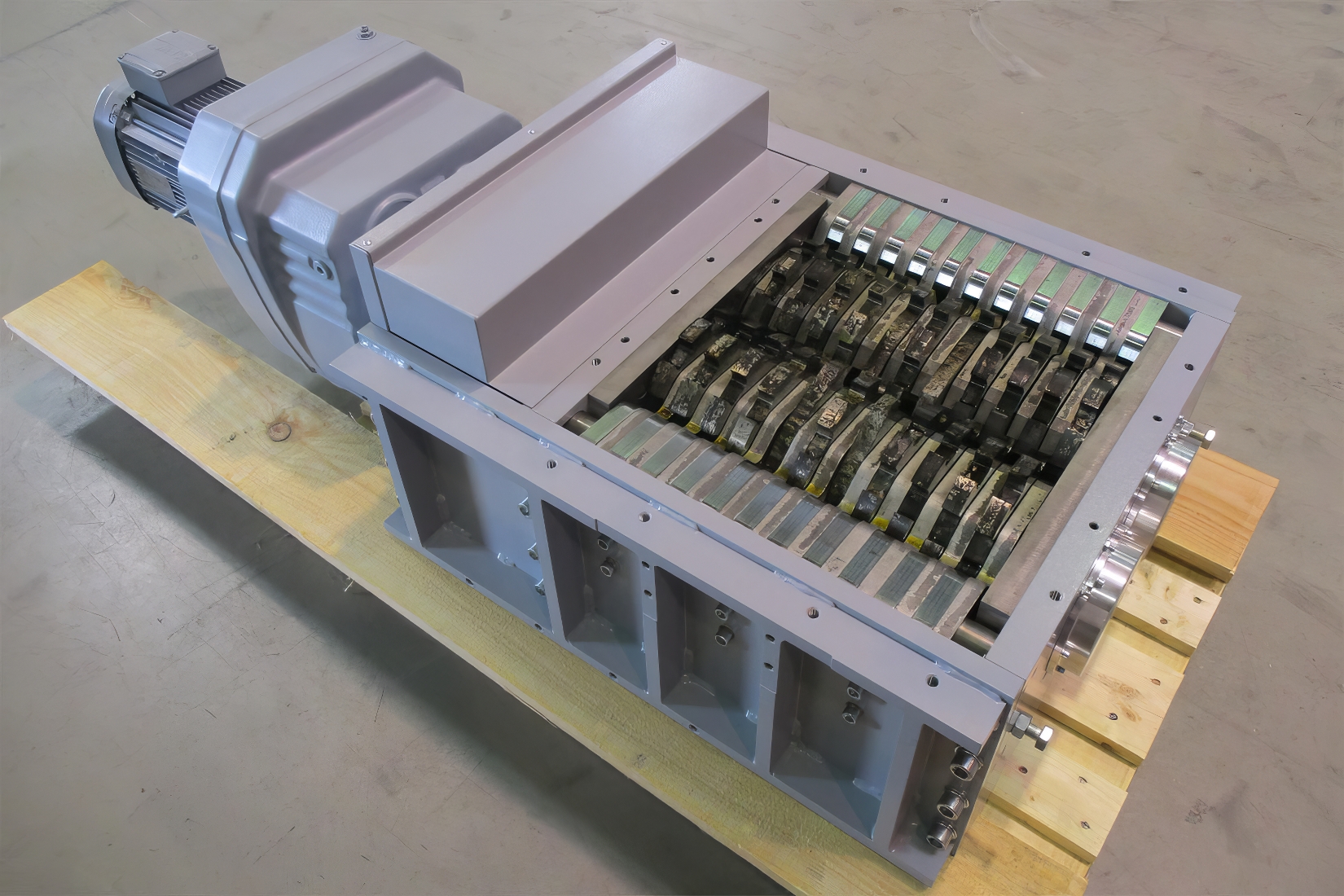

Dual Shaft Shredding Machines – ARP ZW & R Series

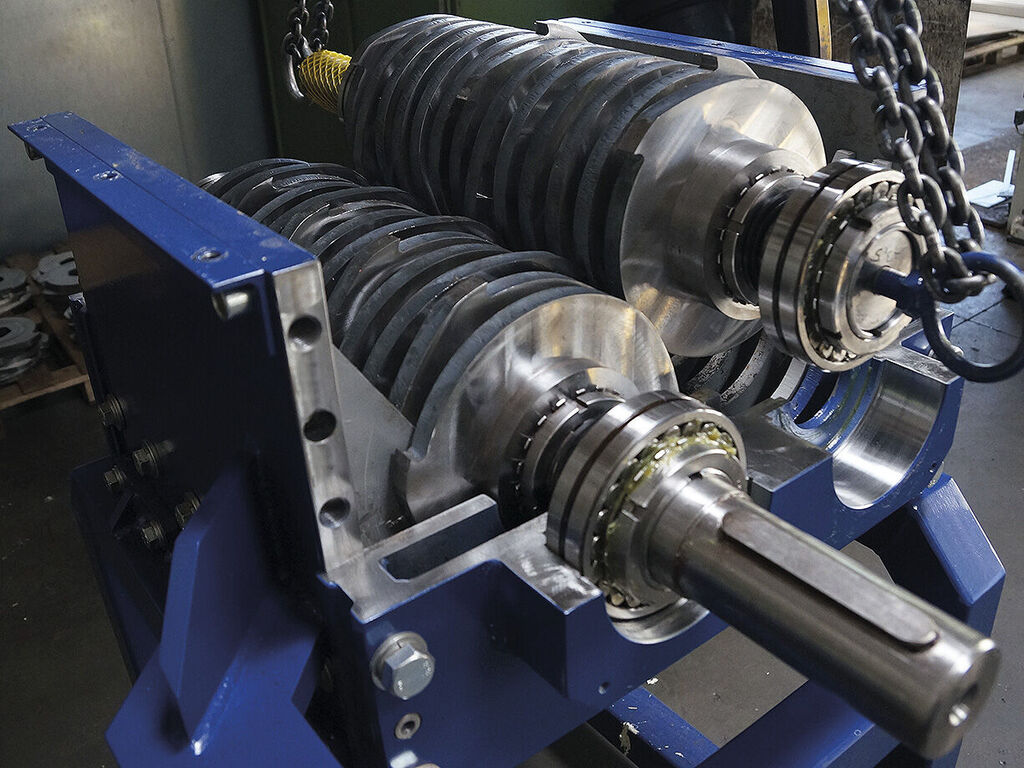

The ARP ZW and R series dual-shaft shredders are high-performance machines designed for volumetric reduction and material preparation, ensuring consistent granulate sizes for transport, pumping, or further processing. Suitable for a wide range of applications, they handle materials such as metal chips, plastics, rubber, textiles, tyres, glass, industrial and household waste, as well as specialised items like fluorescent tubes and hospital waste. Their robust construction features an accessible cutting chamber with interchangeable blades, spacers, and counter-blades, minimising maintenance costs and downtime.

With models tailored for varying capacities, the ZW series includes options like the ZW 500, which processes up to 400 kg/h of steel and 250 kg/h of aluminium, and the ZW 900, capable of handling 2000 kg/h of steel and 1500 kg/h of aluminium. For heavy-duty needs, the R1200 delivers industrial-scale shredding with a 45-55 kW motor. These shredders offer configurable blade setups for diverse materials, combining durability, efficiency, and flexibility to meet the demands of modern recycling and waste management operations.

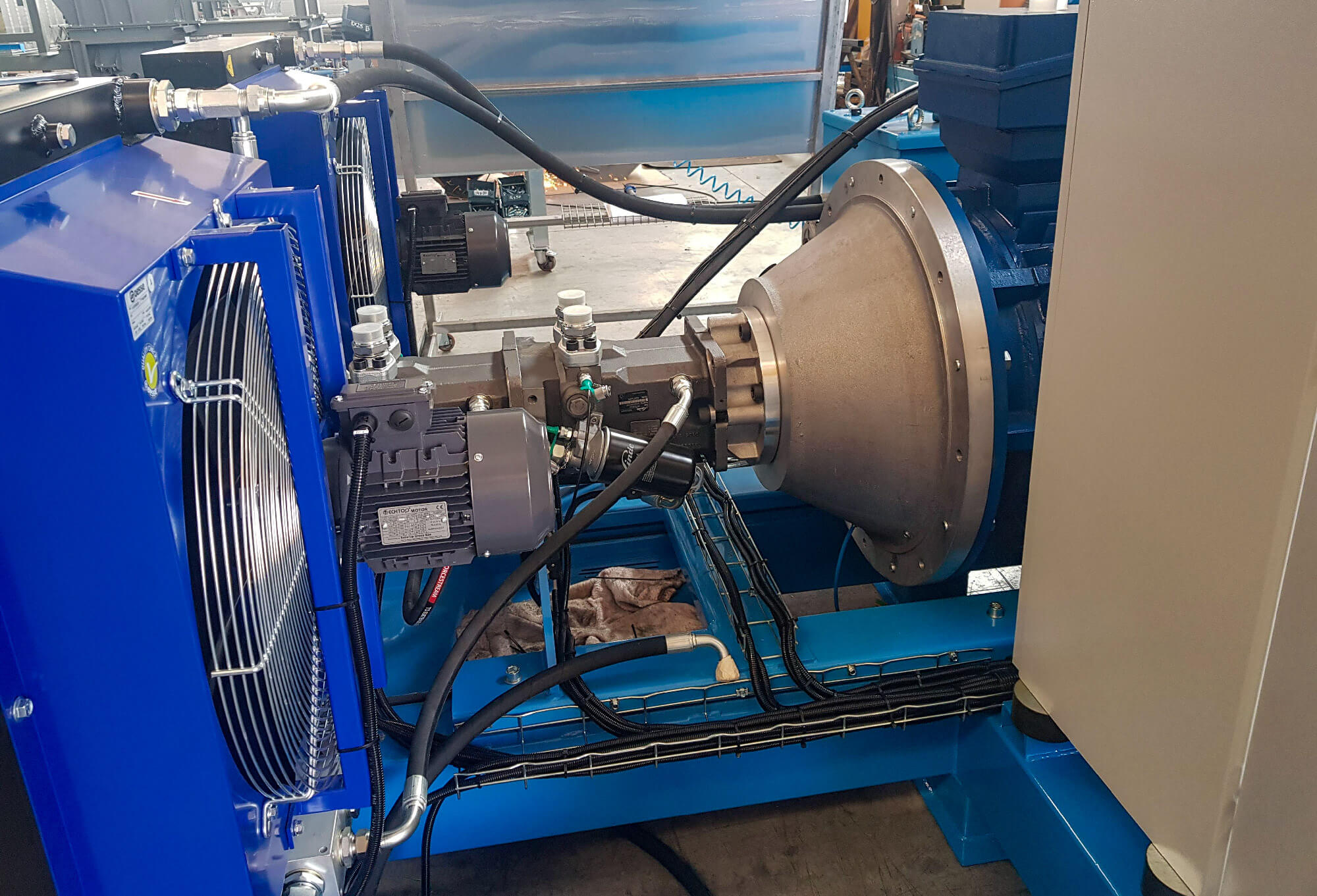

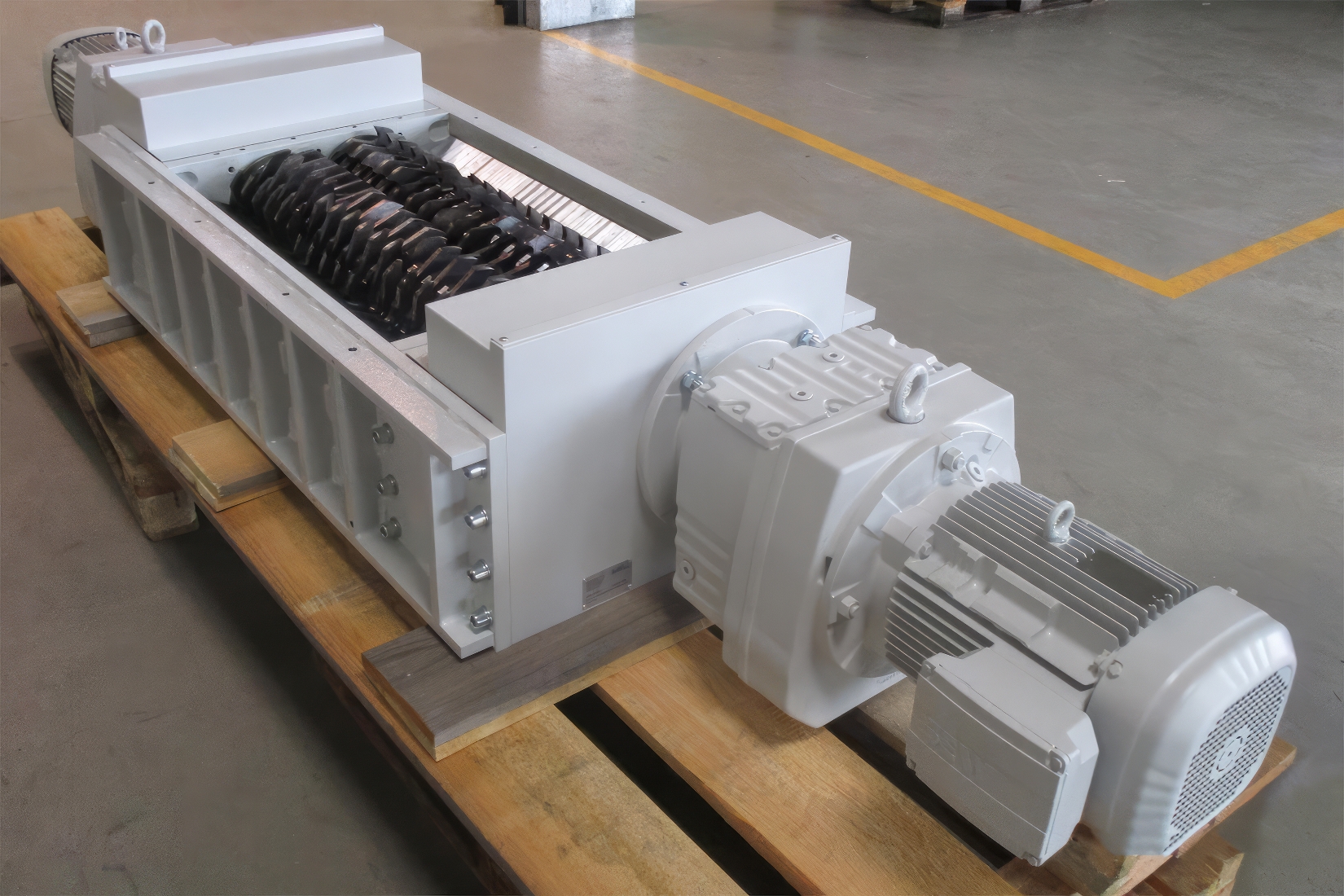

Dual Shaft Shredding Machines – WAGNER ProShred Series

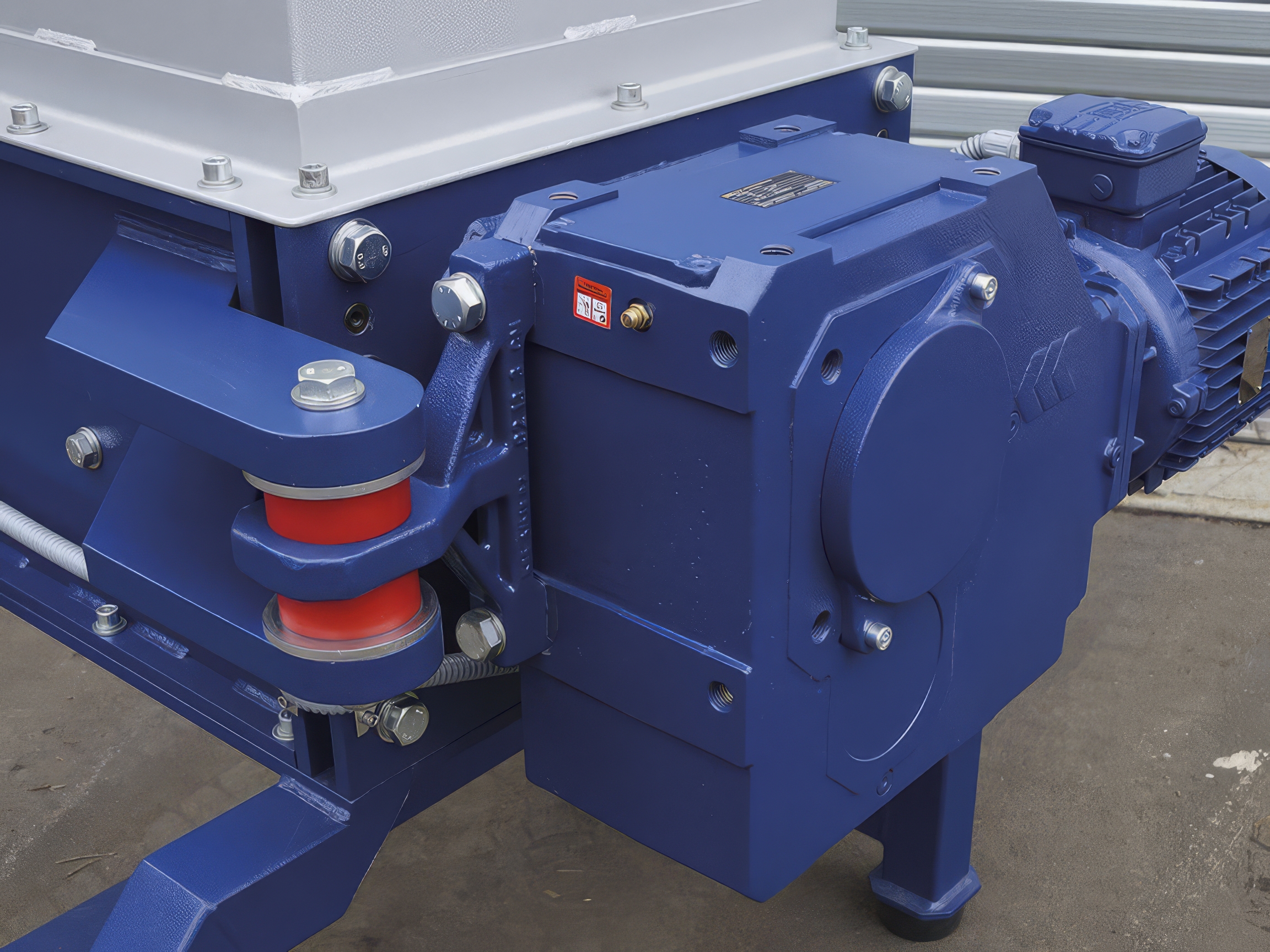

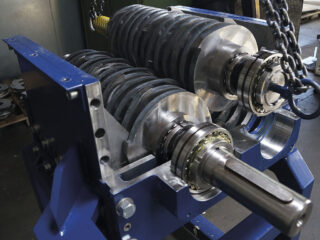

Wagner Twin-Shaft Shredders deliver efficient and economical shredding for a wide range of materials, including plastics, liquid and biological waste, electronic waste, metal shavings, oil filters, paper, wood, and industrial waste. Built with a robust, compact bolted housing, these shredders ensure durability in demanding environments. Self-aligning roller bearings are protected from dirt and liquids with bulkheads and seals, while shredding shafts can be replaced quickly and easily for minimal downtime. High-quality cutting discs, available in various geometries and materials, work with precise knife alignment to ensure effortless shredding of diverse materials.

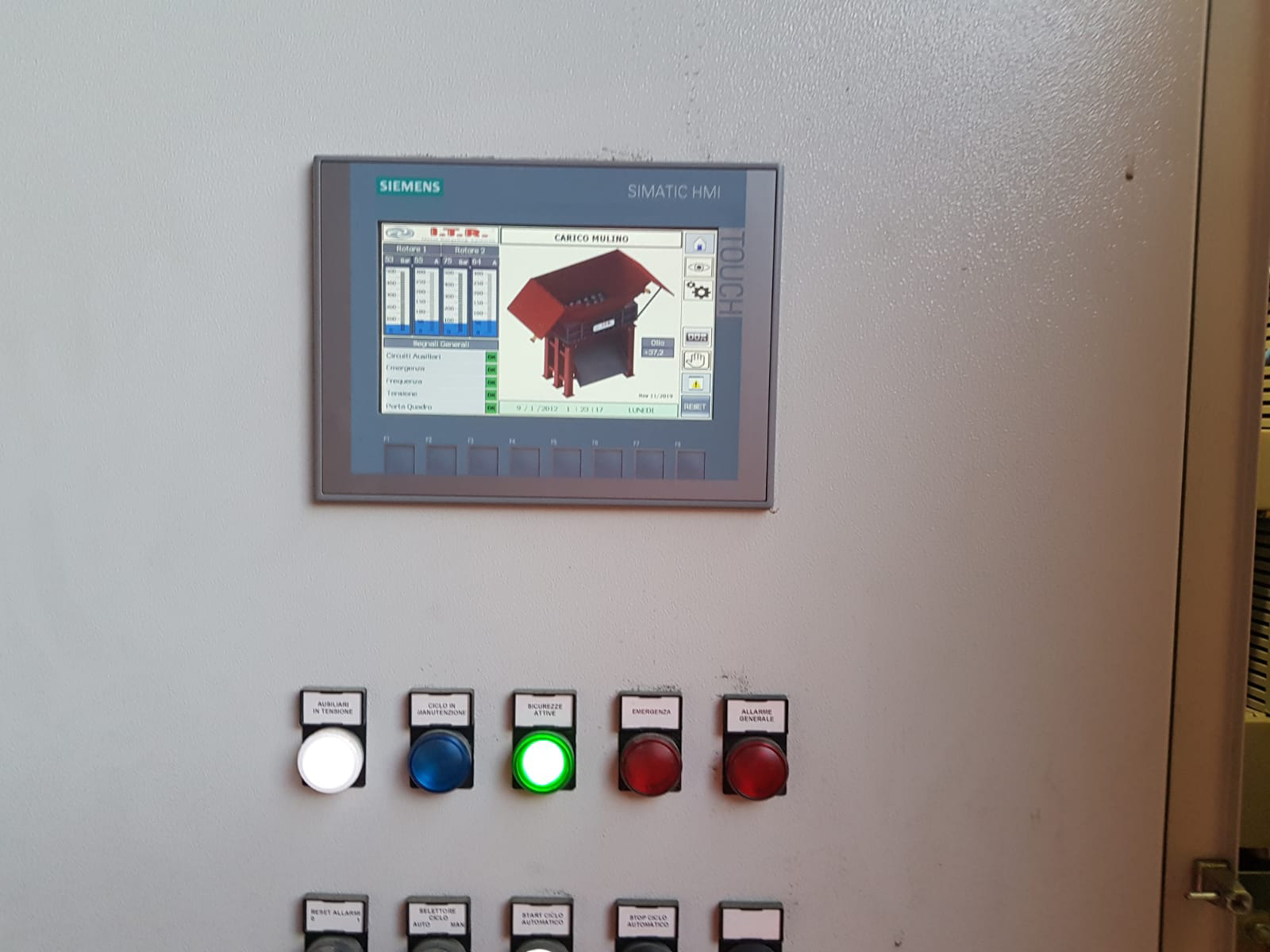

Equipped with a proven drive system, the shredders feature slip-on gear units with rubber bearings, ensuring low-maintenance operation, consistent torque, and reduced wear, noise, and dust. The innovative control system simplifies operation with a user-friendly display, allowing quick selection of work programs and intelligent activation of drives for increased throughput. Overload protection and real-time status notifications further enhance performance and reliability, making Wagner Twin-Shaft Shredders a powerful solution for industrial and recycling applications.