Stationary Trommel (Rotating) & Vibrating Screens and Equipment

SCREENS

Rotating (Trommel) & Disc Screens

These machines produced by ITR Recycling Technologies are designed for the mechanical pre-processing of MSW, and allow the waste materials to be separated by size.

The interchangeable perforated metal sheets or grilles allow the waste or processed material to be divided into two or more sizes; undersize material (that which passes through the holes in the metal sheet), and oversize material (that which, being larger than the holes in the perforated metal sheet, remains on top of the metal sheet itself).

Dynamic disc screens are also used for the mechanical pre-treatment of MSW, facilitating dimensional separation. By adjusting the rotation and speed of the discs, these screens separate the material into two streams: undersized material and oversized material.

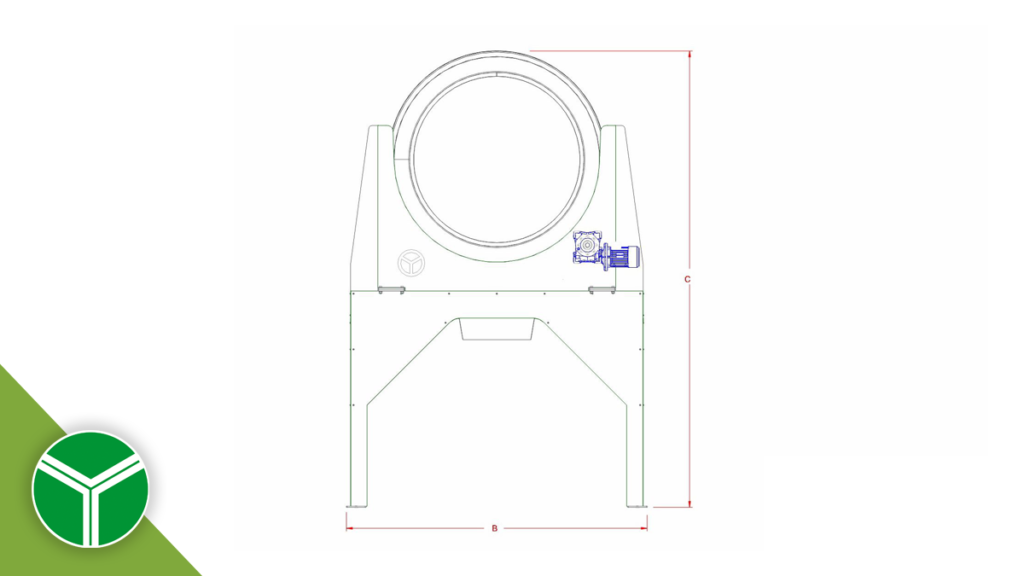

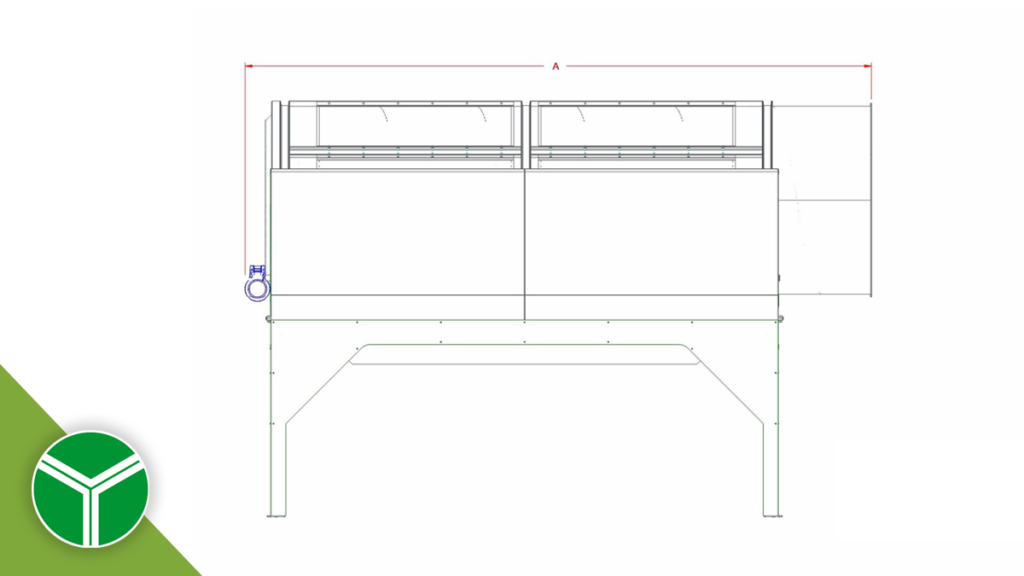

Rotating (Trommel) Screens – TECNOFER

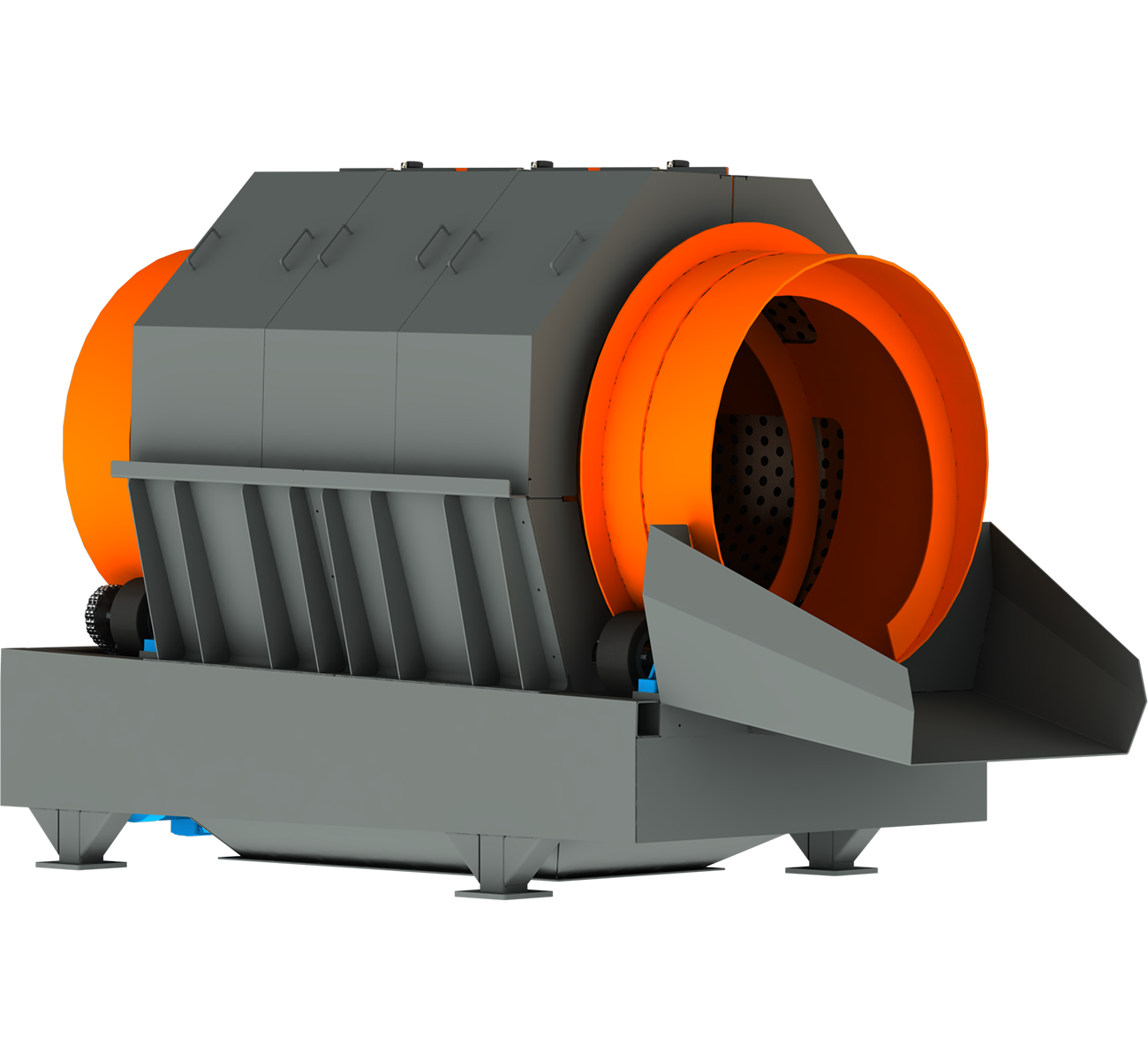

TECNOFER’s Trommel is a robust rotary screen designed to separate and classify plastic materials based on size, making it an essential component in plastic recycling lines. The cylindrical drum features perforations or mesh openings that allow smaller particles, such as dirt, dust, or granules, to pass through while larger materials are retained and conveyed for further processing. This mechanical separation process improves the quality of the plastic material and reduces contamination in downstream equipment.

Built for durability, the Trommel is constructed with high-quality materials to withstand the wear and tear of continuous operation. Its design includes adjustable rotation speed and customizable drum perforations to accommodate different material types and recycling requirements. The Trommel integrates seamlessly with TECNOFER’s other recycling machinery, enhancing efficiency and ensuring consistent material flow throughout the process. With its reliability and adaptability, the Trommel is a critical tool for achieving high-quality results in plastic recycling systems.

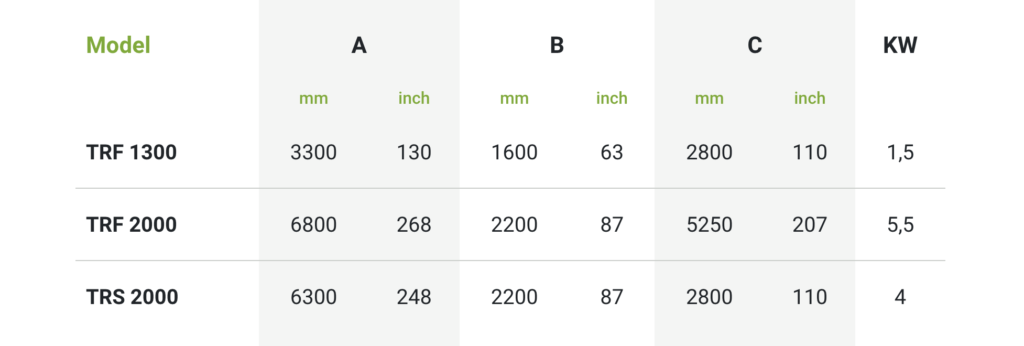

Drawing | Dimensions & Capacities

Rotating (Trommel) Screens – ZEMMLER

The ZEMMLER® MULTI SCREEN® range offers various mobile screening machines with double trommel technology tailored for different applications:

-

MS 6700-ST: The largest in the range, this machine has over 60 m² of screening area and a trommel length of 6.70 m, delivering up to 180 m³/h. It’s designed for high throughputs and small mesh sizes.

-

MS 5200-ST: With compact dimensions, it easily integrates into most screening lines. It features a 47 m² double trommel driven by a powerful electric engine and is adaptable to different applications and sites.

-

MS 3200-ST: Ideal for landscaping and soil prep, this model also uses proven double trommel technology. An optional slip-on ring enables screening into three fractions, while wire screen coverings ensure a clean, sharp separation.

-

MS 1600 Starter: The smallest option, designed for smaller users like landscapers, construction firms, or councils. Its lightweight, compact design fits trailers up to 2.5 tonnes, and an optional slip-on ring allows a quick switch from a two-fraction to a three-fraction screening machine.

Drawing | Dimensions & Capacities

Rotating (Trommel) Screens – MLS Makina

The Rotary Screen is a fundamental part of recycling and reflects the essence of Hard Recycle’s business. This durable, high-capacity equipment manufactured by MLS Makina is specially designed to clean and sort your materials. The rotary screen helps you isolate your valuable materials by separating unwanted small particles and dust, making your recycling processes more effective and efficient while maintaining workplace cleanliness and safety with its dust-sealing feature.

Furthermore, the Rotary Screen optimizes the recycling process by facilitating the smoother operation of subsequent machines. More precise separation of valuable materials supports sustainable recycling. Therefore, by introducing rotary screens from MLS Makina to the Australian market, we take pride in offering this essential equipment not only to various businesses but also in promoting sustainable recycling across the industry. Highlighting the importance of recycling and our commitment to conserving natural resources is a cornerstone of our business.

Vibrating Screens

The material introduced into the vibrating screen is moved by the combined effect of horizontal and vertical vibrations generated by the vibrating masses. As it progresses along the screening mesh, the material is efficiently separated, ultimately channeling the desired fractions toward the discharge.

Depending on operational requirements, ITR Recycling Technologies can design and manufacture vibrating screens of various sizes and throughput capacities, thereby increasing both hourly flow and overall screening efficiency.

By employing this solution, powders and granules of different diameters are separated effectively, ensuring optimal material classification for downstream processes and enhancing the overall recycling or production workflow.

LANNER Siebmaschine (Vibrating Screener)

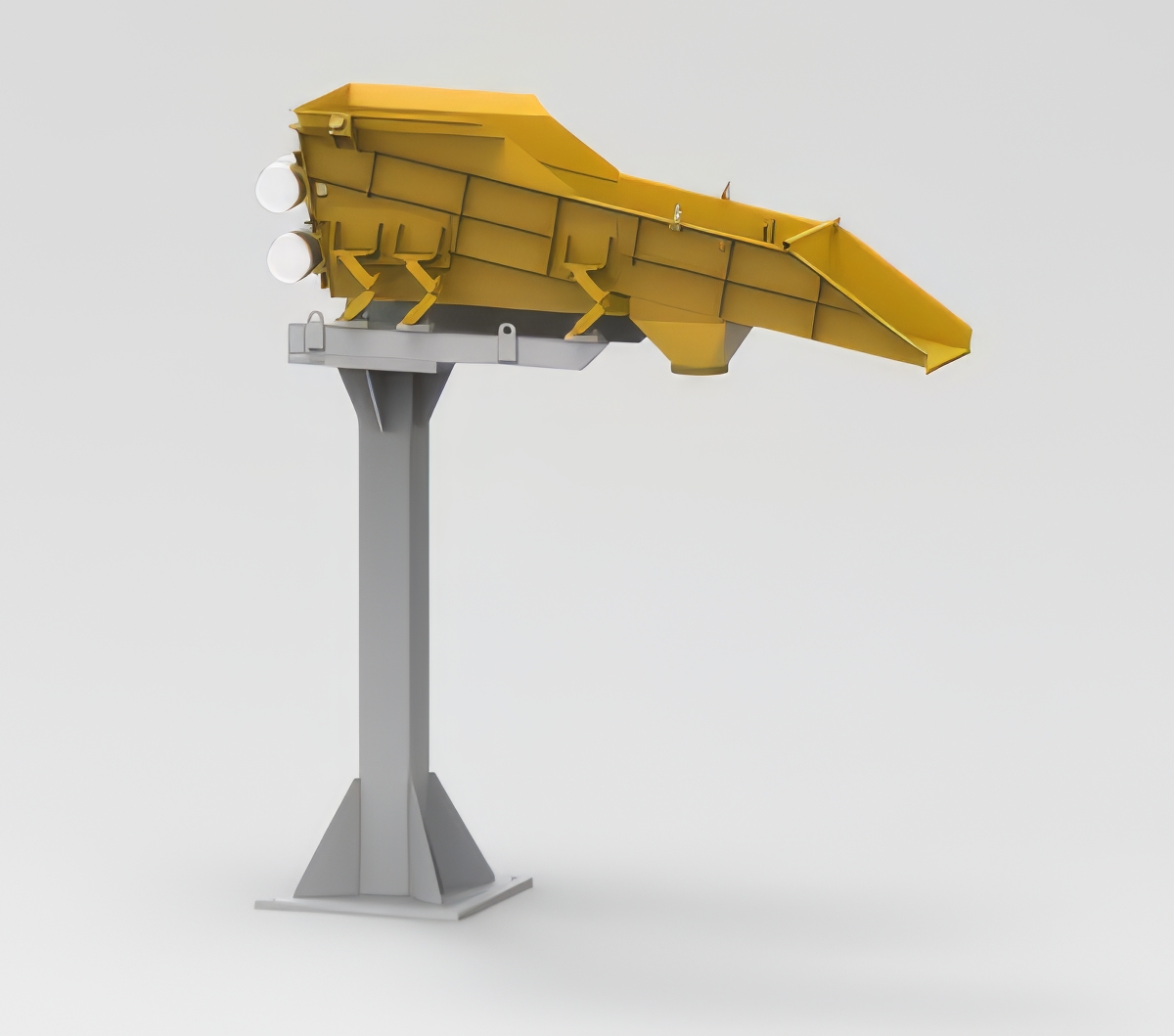

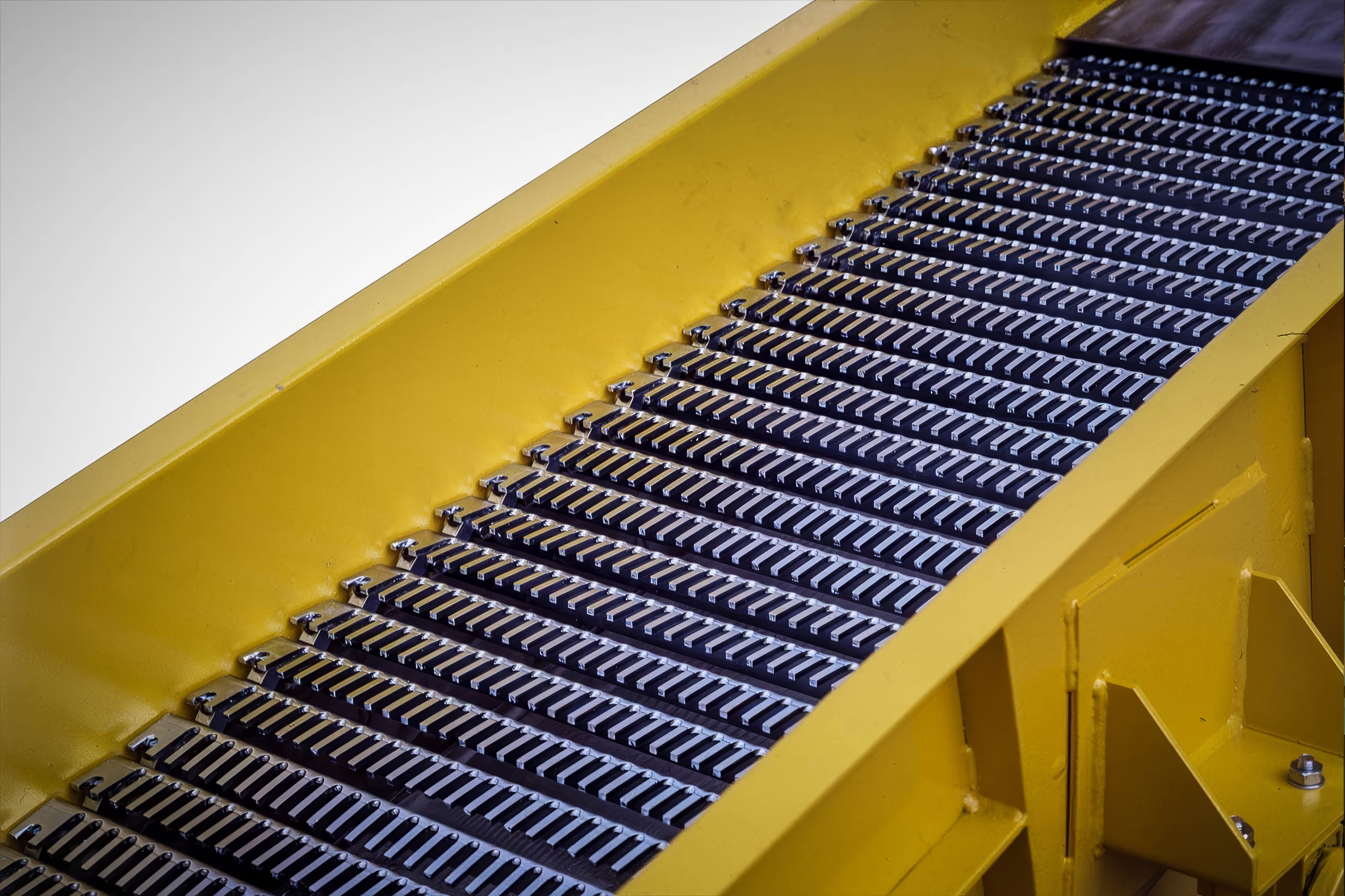

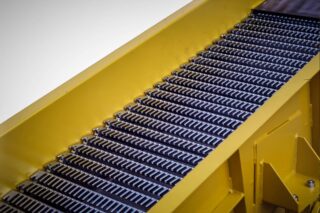

LANNER‘s Siebmaschine (Screener) is engineered to efficiently separate free-flowing metal chips from tramp metals and chip nests, ensuring optimal material preparation for subsequent processing stages. The system operates by continuously feeding material, typically via a steel belt conveyor, onto a vibrating screen. This vibration facilitates the separation process: short, free-flowing chips pass through the sieve for further processing, while larger tramp metals and chip nests are directed to a separate collection area.

Key features of the Siebmaschine include adjustable cascades and frames, allowing customization to specific material requirements, and unbalance drives that can be fine-tuned to achieve precise separation results. The screener’s design also incorporates a pivoting stand, simplifying maintenance procedures and reducing downtime. By effectively removing unwanted materials, the Siebmaschine enhances the efficiency and reliability of downstream processes such as centrifuging or briquetting, making it a valuable component in metal chip processing systems.