Presses and Squeezers

PRESSERS, DRYERS AND HOT THERMAL UNITS

Waste Squeezer – TECNOFER

TECNOFER’s Waste Squeezer is a high-performance system designed for drying and densifying plastic materials, particularly films and flexible plastics, after the washing process. It operates using a robust mechanical screw press that applies controlled pressure to reduce moisture content to below 3%, effectively removing over 97% of residual water. The system’s design integrates a perforated cylinder for efficient water drainage and a high-torque screw mechanism to ensure consistent material flow.

Compared to traditional thermal drying methods, the Squeezer significantly reduces energy consumption—up to 70%—making it a cost-effective and environmentally friendly solution. Its advanced engineering optimises material preparation for downstream processes like extrusion or pelletising. Built with durability and low-maintenance features, the Waste Squeezer ensures long-term reliability and enhanced efficiency for modern plastics recycling operations.

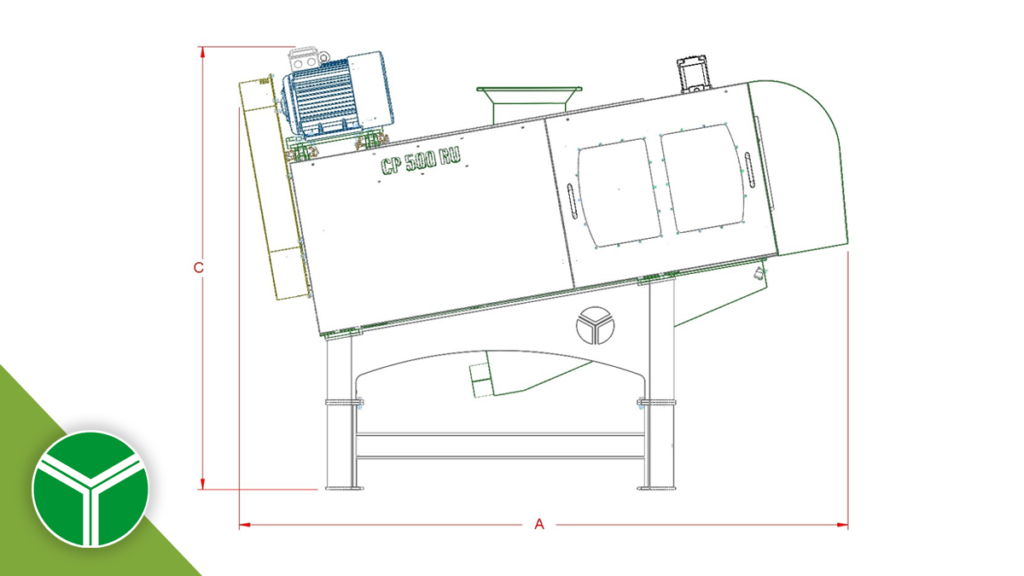

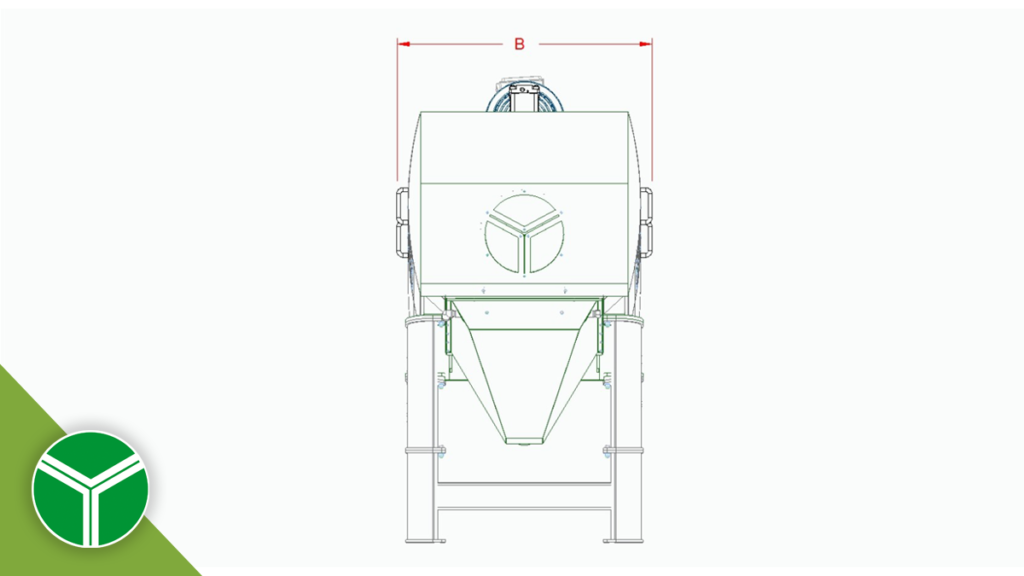

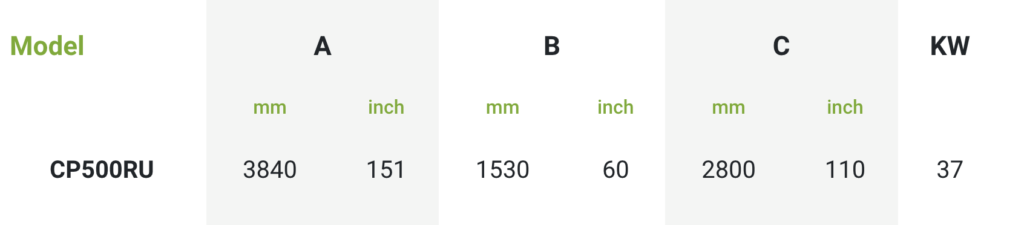

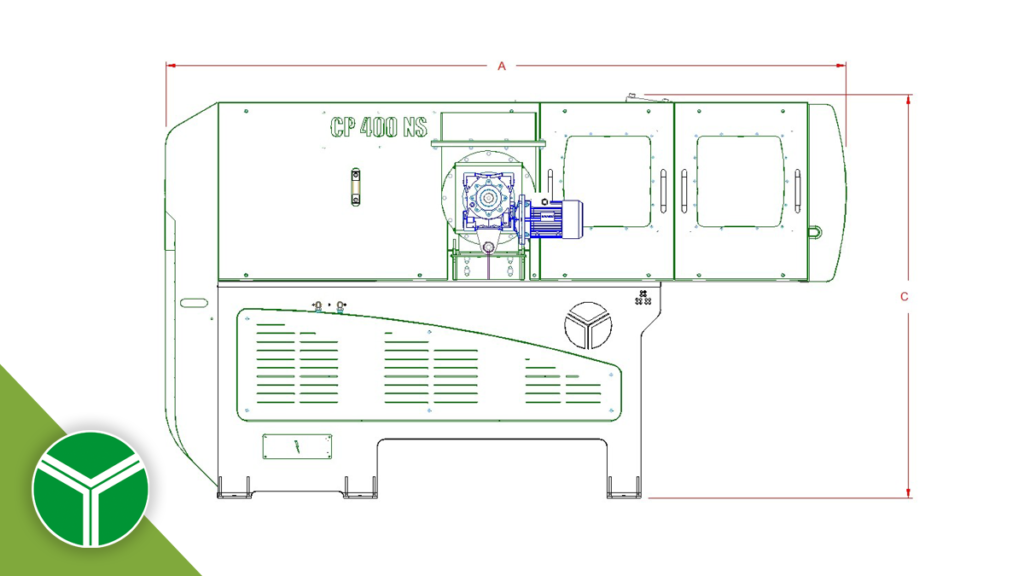

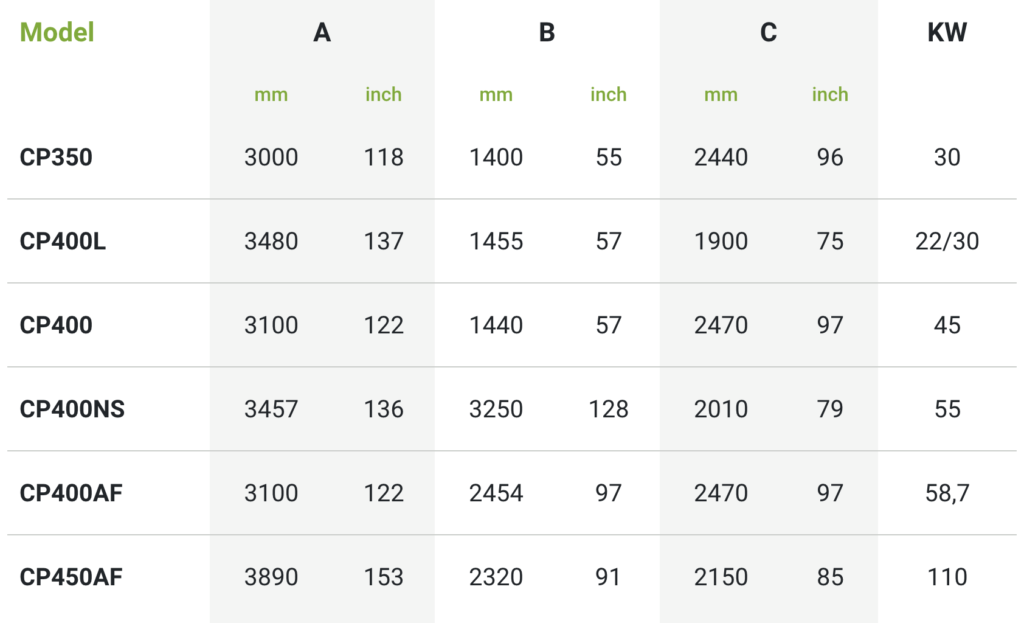

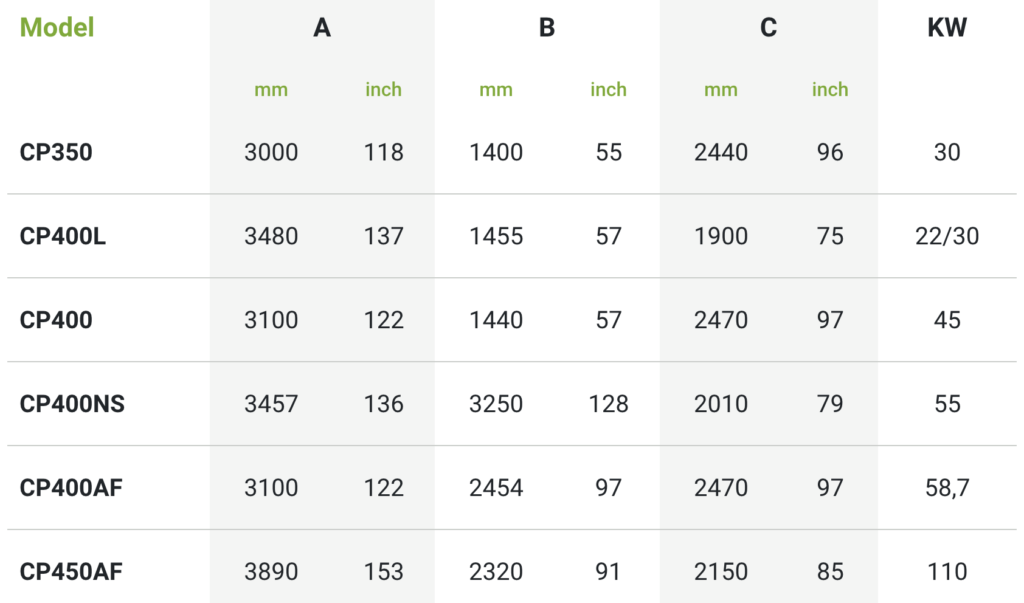

Drawing | Dimensions & Capacities

Screw Presses for Pulper Rejects – TECNOFER

TECNOFER’s Screw Press for Pulper Rejects is an efficient system for processing materials such as plastics and fibrous residues from paper pulping operations. Designed for heavy-duty applications, the screw press reduces the moisture content of pulper rejects from initial consistencies of 8-10% solids to an output consistency of up to 90%, depending on the material.

The system features a robust screw press mechanism with adjustable backpressure and temperature controls, ensuring optimal performance across various material types. By extracting water and densifying the material, it significantly reduces disposal costs and maximises the recovery of valuable materials. Its durable construction and energy-efficient design make it an essential solution for industries handling pulper rejects or similar waste streams.

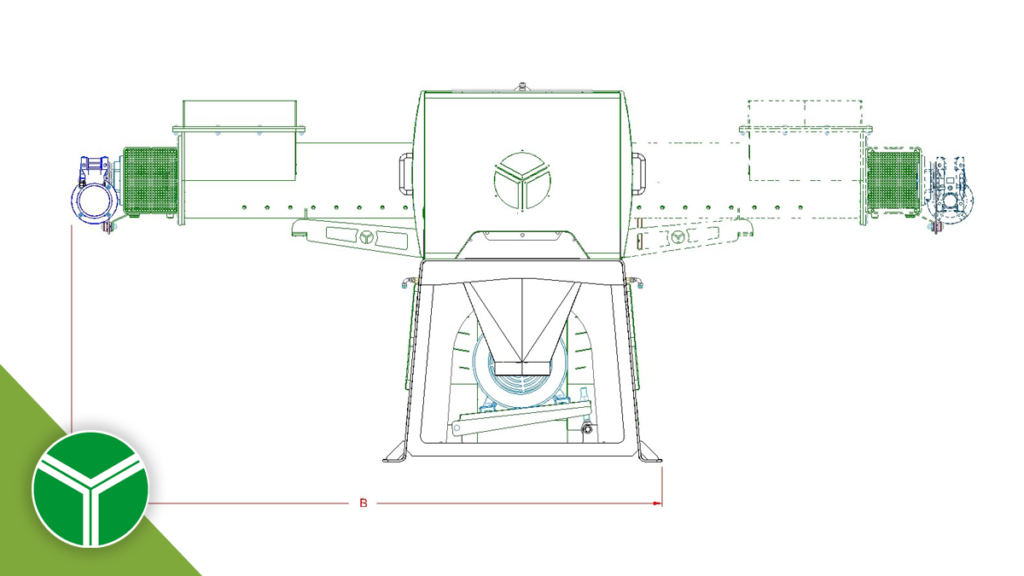

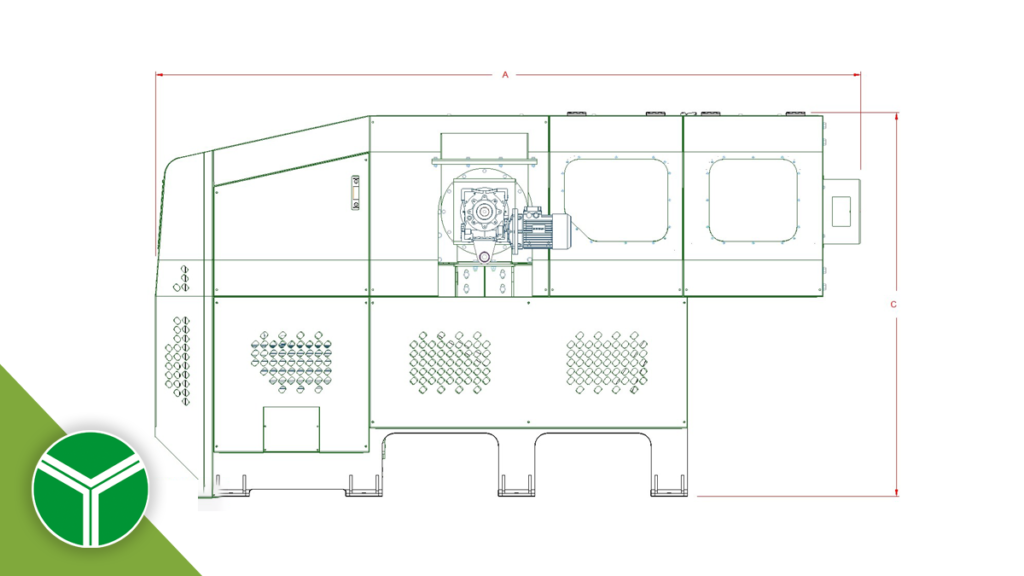

Drawing | Dimensions & Capacities

Screw Presses for Organic Waste – TECNOFER

TECNOFER’s Squeezer for Organic Waste is an advanced system engineered to efficiently dewater and densify organic materials, including food waste, compost, and biodegradable plastics. The system operates using a robust screw press mechanism that reduces moisture content to less than 30%, significantly lowering the weight and volume of waste for transport and disposal.

Designed for high performance, the Squeezer’s perforated cylinder and high-torque screw ensure consistent processing, even with materials of varying composition. This not only optimises waste management operations but also enhances the preparation of organic waste for subsequent treatment processes, such as anaerobic digestion or composting. Its energy-efficient operation, low maintenance requirements, and durable construction make it a sustainable and cost-effective solution for organic waste processing.

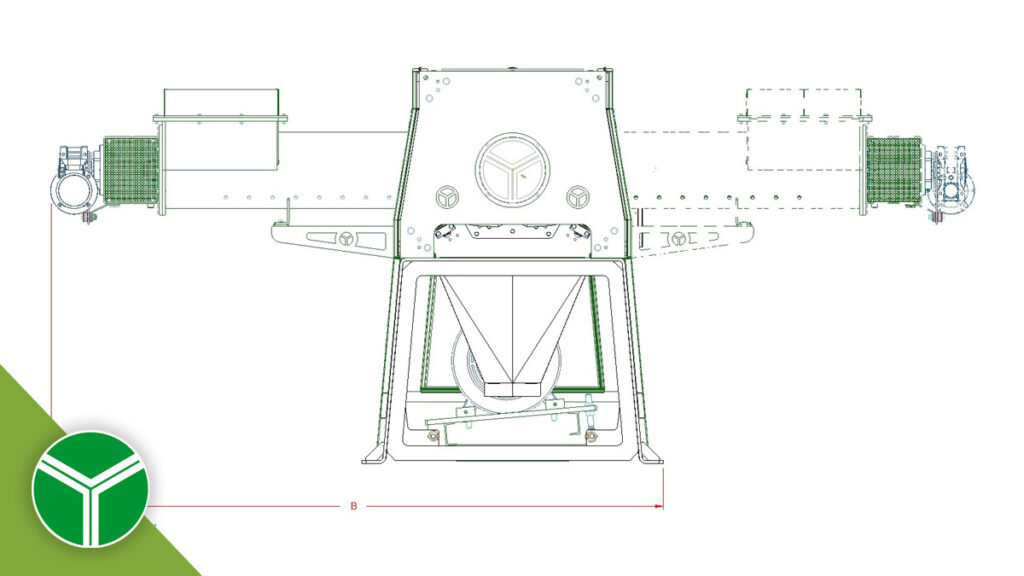

Drawing | Dimensions & Capacities