Pre-Washing, Washing and Flotation Tanks

Tanks for Plastics Recycling Industry

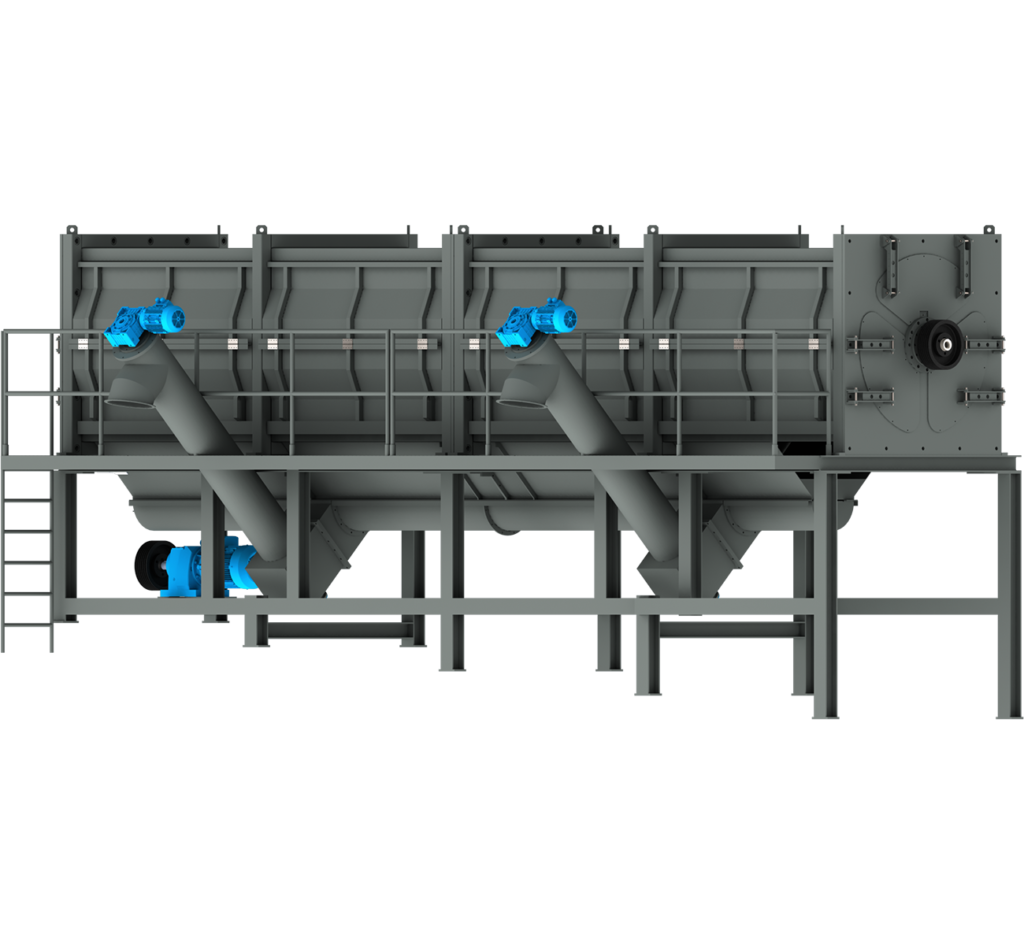

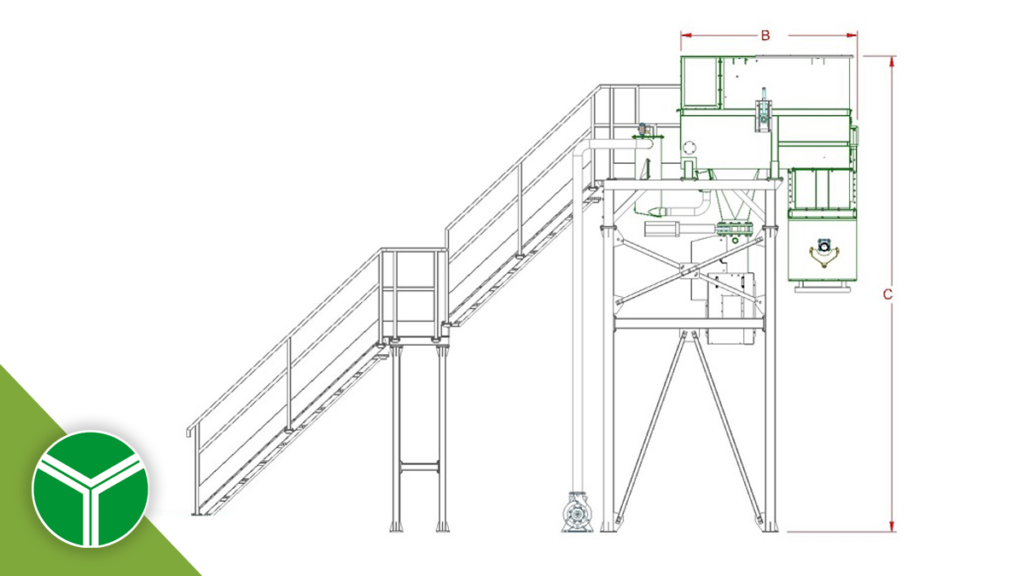

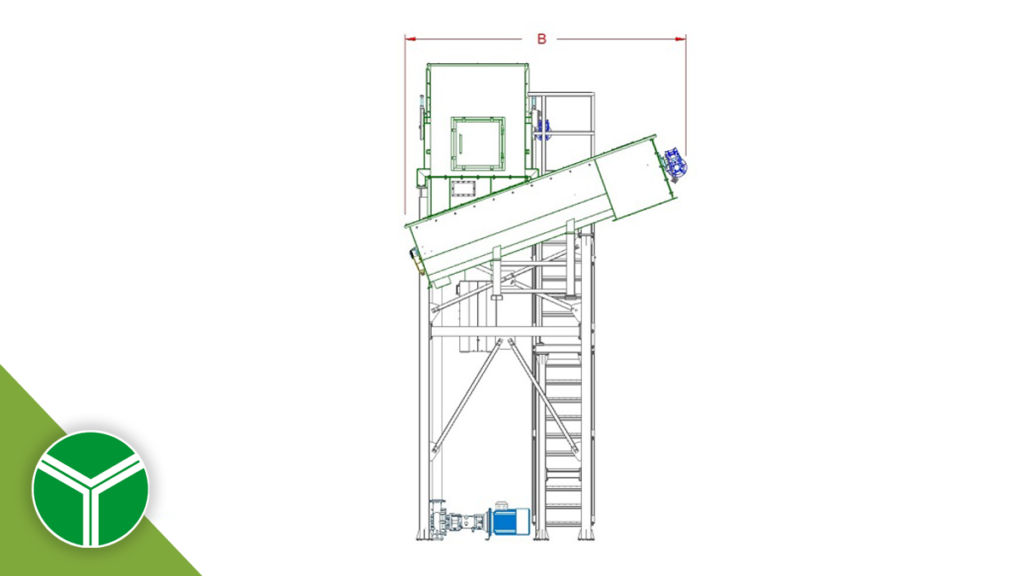

Pre-Washing Tank – TECNOFER

TECNOFER’s Pre-Washing Tank is a specialised system designed for the initial cleaning and separation of plastic materials in recycling processes. Using a water-based density separation method, it removes heavy contaminants such as stones, metals, and glass, ensuring the plastic feedstock is pre-cleaned before entering subsequent washing stages.

The tank operates with controlled agitation and water flow to separate heavier impurities, which settle at the bottom for easy discharge, while lighter plastic materials remain on the surface. The system is equipped with automatic discharge mechanisms for contaminants, ensuring continuous operation and reduced manual intervention. Its design enhances the overall efficiency of recycling lines by minimising wear and tear on downstream equipment and improving the quality of the recycled plastics.

Built with durable materials to withstand heavy-duty operations, Tecnofer’s Pre-Washing Tank is ideal for handling high volumes of contaminated plastic waste, making it a crucial component for modern, efficient plastic recycling workflows.

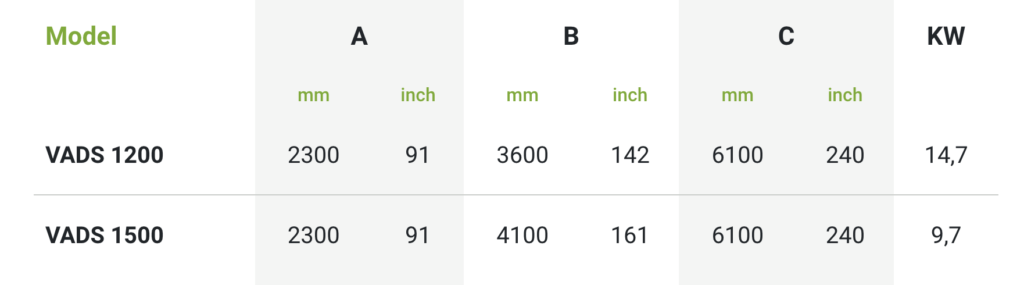

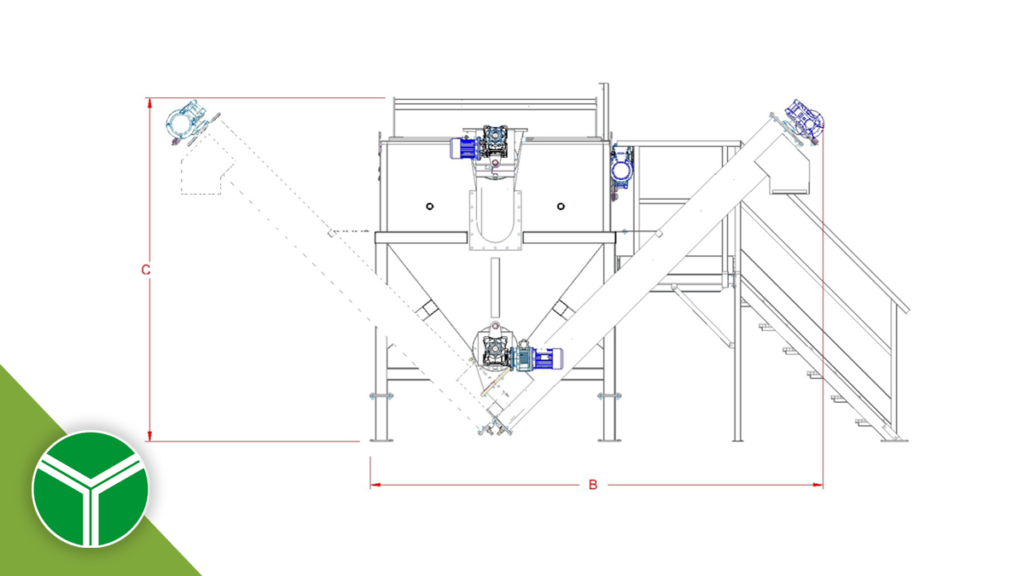

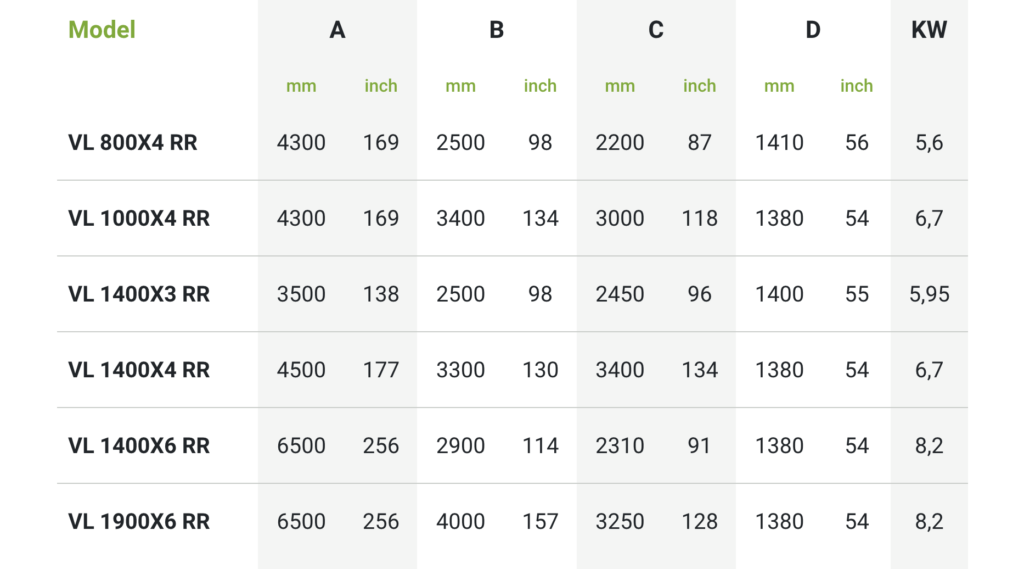

Drawing | Dimensions & Capacities

Plastic Pre-Wash Stations | MLS Makina

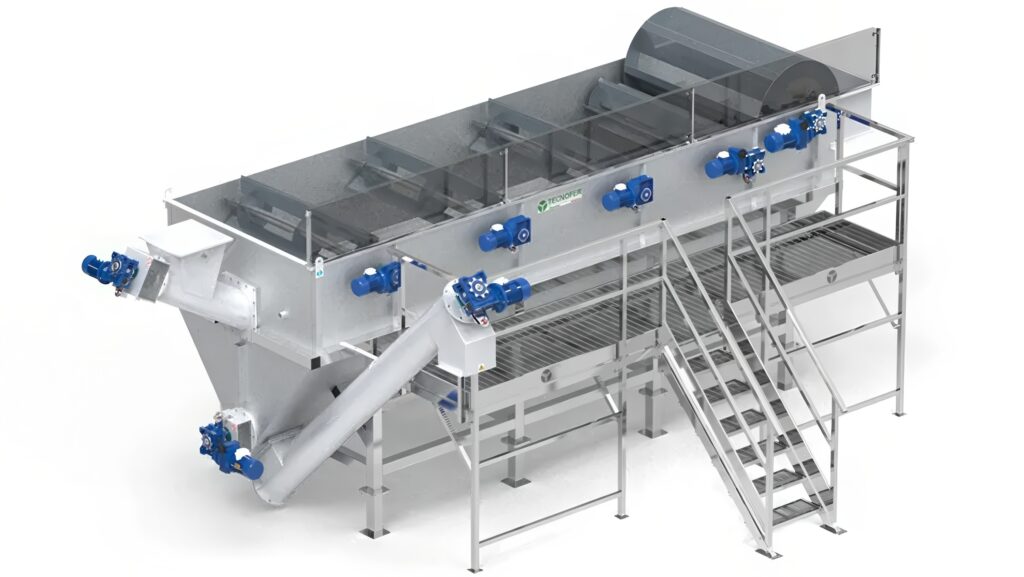

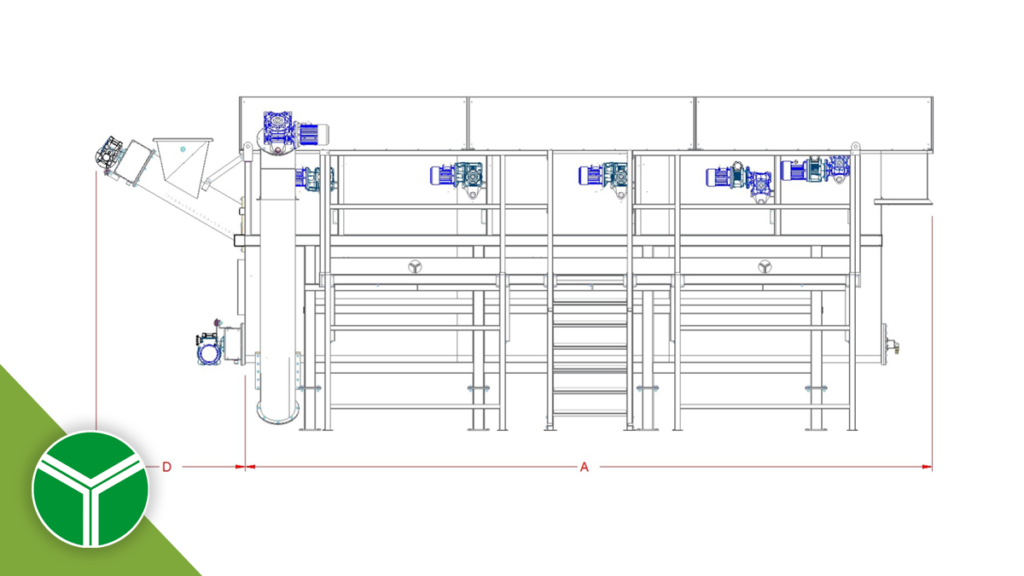

Washing Tanks – TECNOFER

TECNOFER’s Washing Tank is a specialised system for cleaning plastic flakes by removing lighter impurities such as labels, dirt, and residual adhesives. It is an integral part of plastics recycling, designed to process and prepare materials like PET, HDPE, and PP for further stages in the recycling line.

The tank operates by submerging the plastic flakes in water and utilising controlled agitation and water flow to dislodge contaminants. Lighter impurities float to the surface and are skimmed off, while clean plastic flakes are directed toward the discharge point for further processing. The Washing Tank’s design optimises the cleaning process by maintaining steady material flow and reducing the risk of blockages or inefficiencies.

Constructed with robust materials to withstand prolonged use, the Washing Tank ensures consistent performance in high-volume recycling operations. Its ability to deliver thoroughly cleaned plastics makes it a vital component in achieving high-quality recycled material output.

Drawing | Dimensions & Capacities

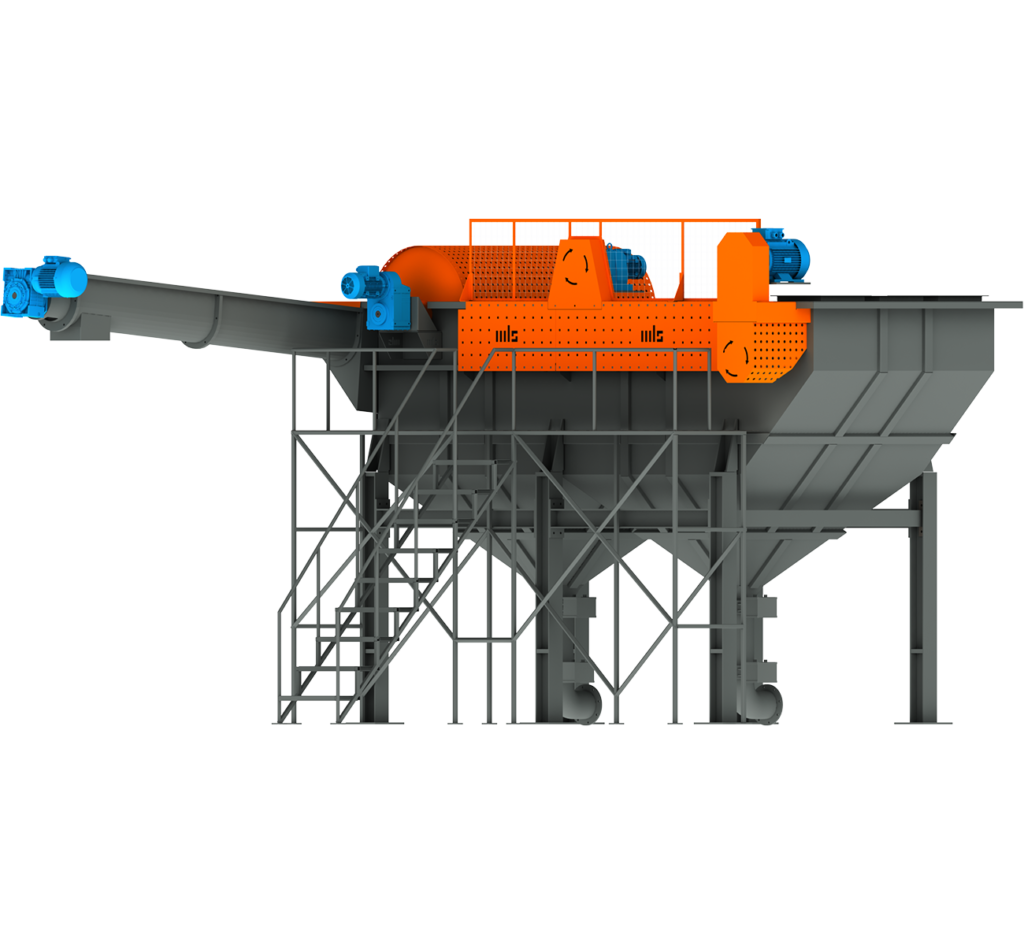

Flotation Tanks | MLS Makina

MLS Makina’s Flotation Tanks are used in plastic washing lines; one of the most important separation machines used to separate plastics that have undergone size reduction from foreign substances such as dust, soil, mud, stones, metals, and paper. Mixed plastics, where high-density materials sink and low-density materials float, are fed into the flotation tank. When materials enter the separation tank, specially designed rotating drums move the materials forward and transport them with water.

Due to the differences in density, flotation & sinking separation tanks can be manufactured in different models and sizes according to various plastic types and operational capacities. Floatation & sinking tanks are customized based on the materials to be processed. Built on a robust construction, these tanks are designed to provide long-term service, making them one of the most important machines in the recycling process with a focus on maximum cleanliness and minimum waste.

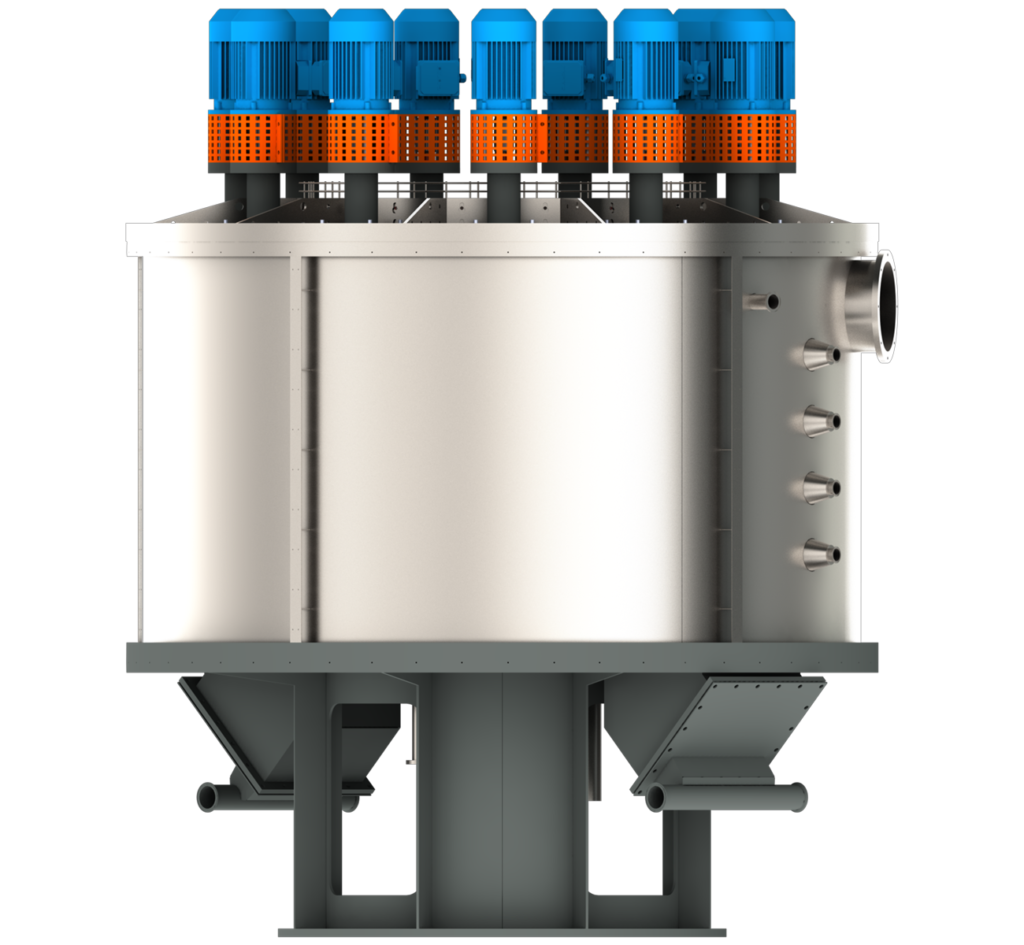

Caustic Washing Tank | MLS Makina

MLS Makina’s Caustic Washing Tank is engineered for industrial cleaning applications, particularly effective in processing PET flakes and removing stubborn contaminants. Its construction features stainless steel inlet units for durability and corrosion resistance, ensuring longevity in harsh industrial environments. An internal support column provides structural stability, while a rotary cover equipped with a mixer ensures thorough agitation of materials, enhancing the cleaning process.

Partition plates are incorporated to facilitate organized flow and separation within the tank, and a water level control system maintains optimal operating conditions, ensuring consistent and efficient cleaning performance.

This tank is particularly effective for cleaning PET flakes and removing stubborn contaminants, making it a reliable choice for industrial cleaning applications.