Equipment for Waste & Metal Treatment Mobile Hammer Mills

MOBILE HAMMER MILLS

Mobile Hammer Mill | ITR HMM 060

Mobile Hammer Mill | ITR HMM 080

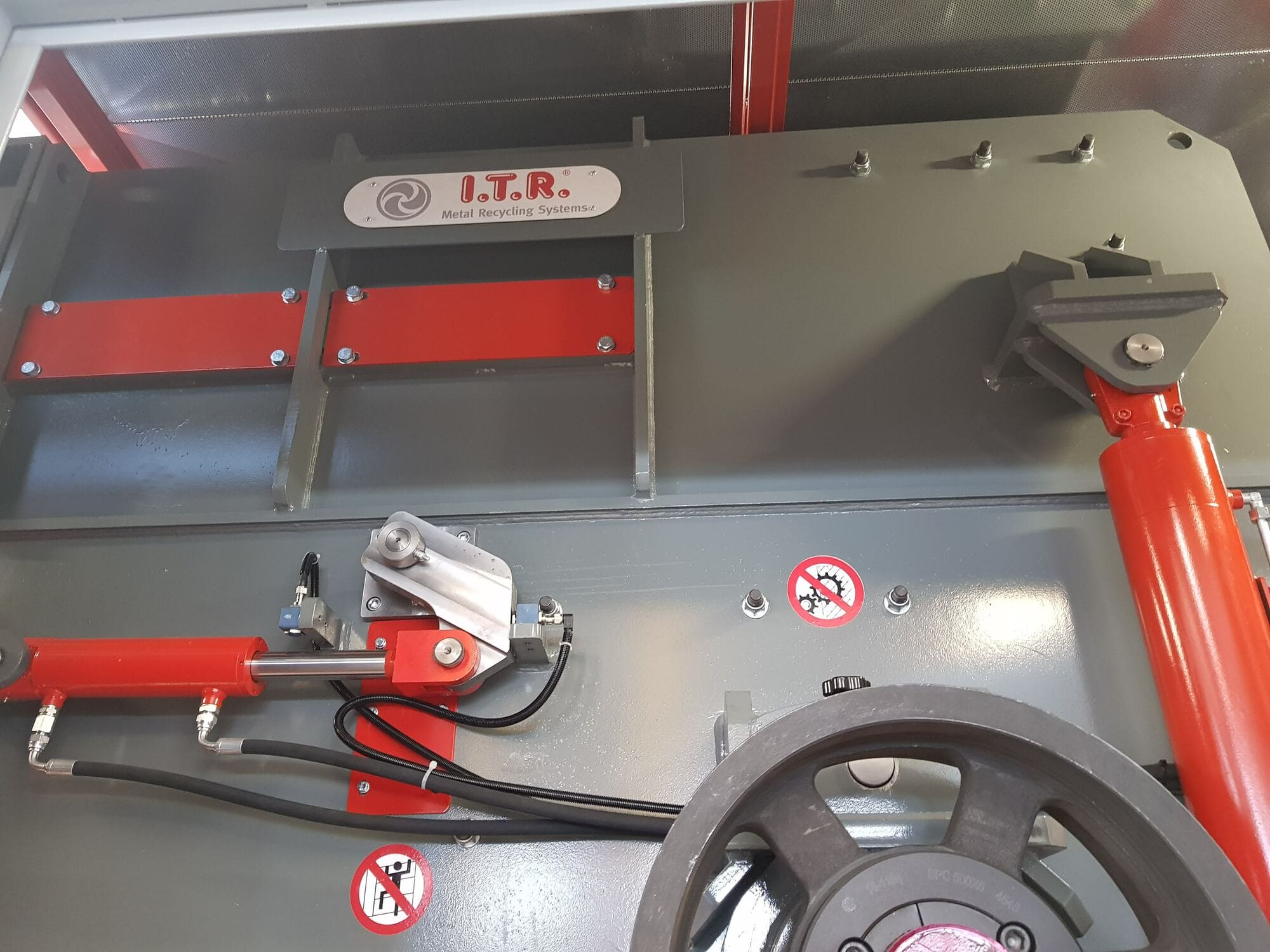

The ITR Recycling System‘s HMM 080 hammer mill is a complete grinding system mounted on a demountable platform, featuring a conveyor belt for material extraction from the soundproof booth and a magnetic drum separator.

Positioned as an intermediate solution between roughing and refining hammer mills, it is equipped with a 160 kW electric motor with a soft starter and a grinding chamber designed for processing medium-small materials, producing an ideal output for subsequent separation processes.

The HMM (Mobile) series shares the core features of fixed hammer mills, including hydraulic operation of main components, rotor lifting via the upper hood, and a quick grid replacement system. These features deliver increased production capacity and reduced operational costs. Compact and mobile, the HMM 080 is designed to meet diverse space and production requirements.

Mobile Hammer Mill | ITR HMM 100

Mobile Hammer Mill Refiner | ITR HMM 130