Chip Pumping Stations and Briquetting Presses

CENTRIFUGES, FRICTION WASHERS & CHIP PUMPING STATIONS & BRIQUETTING PRESSES

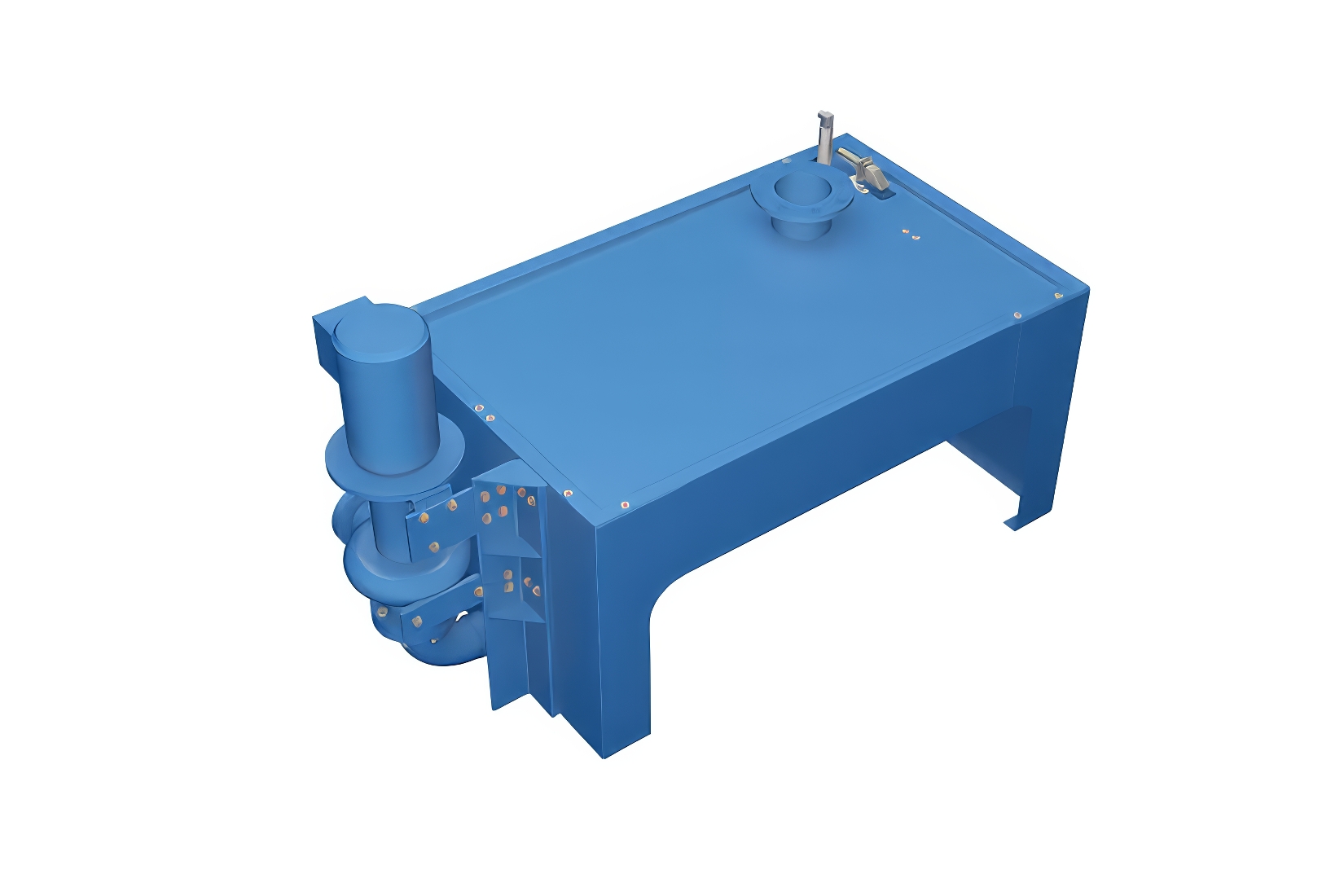

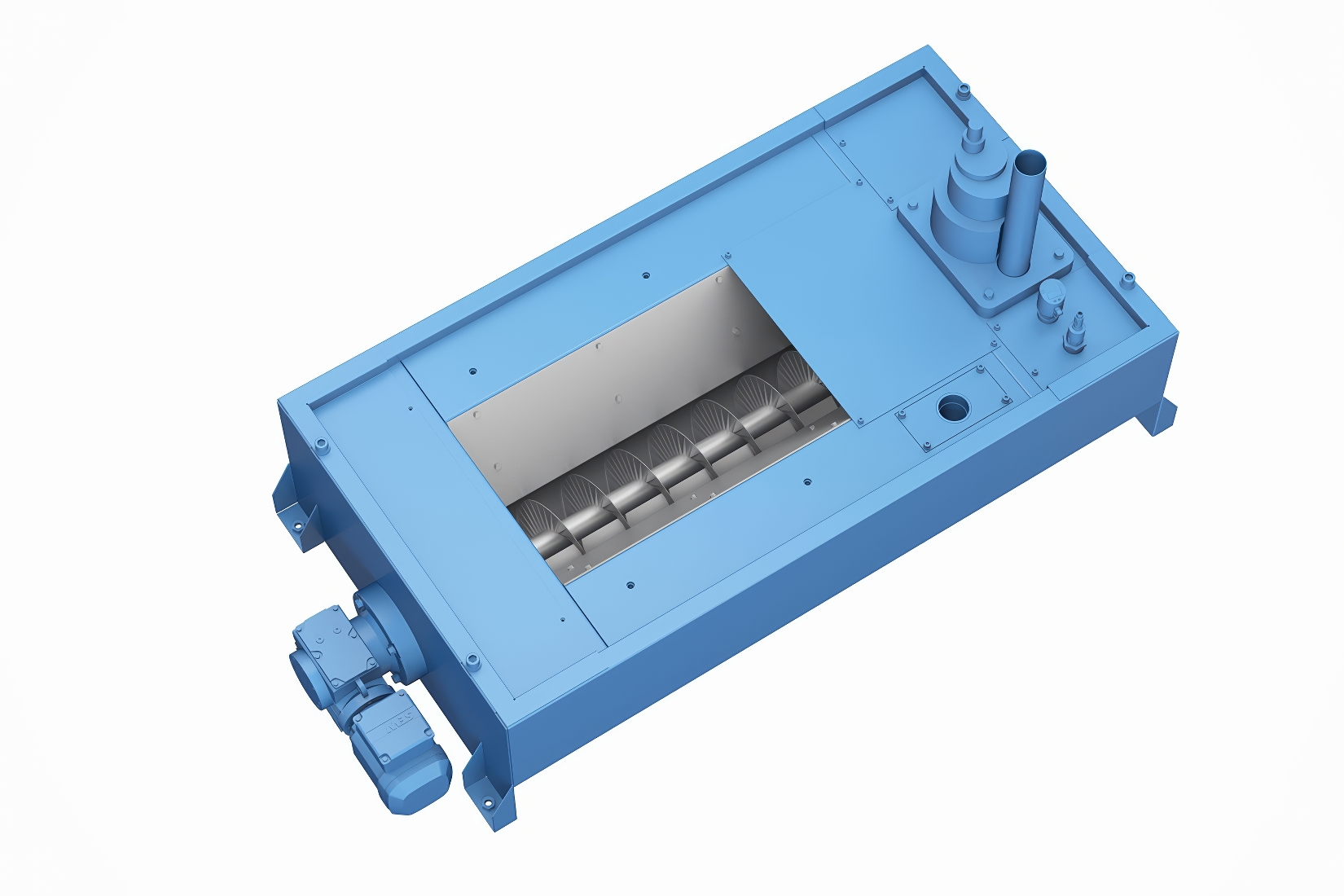

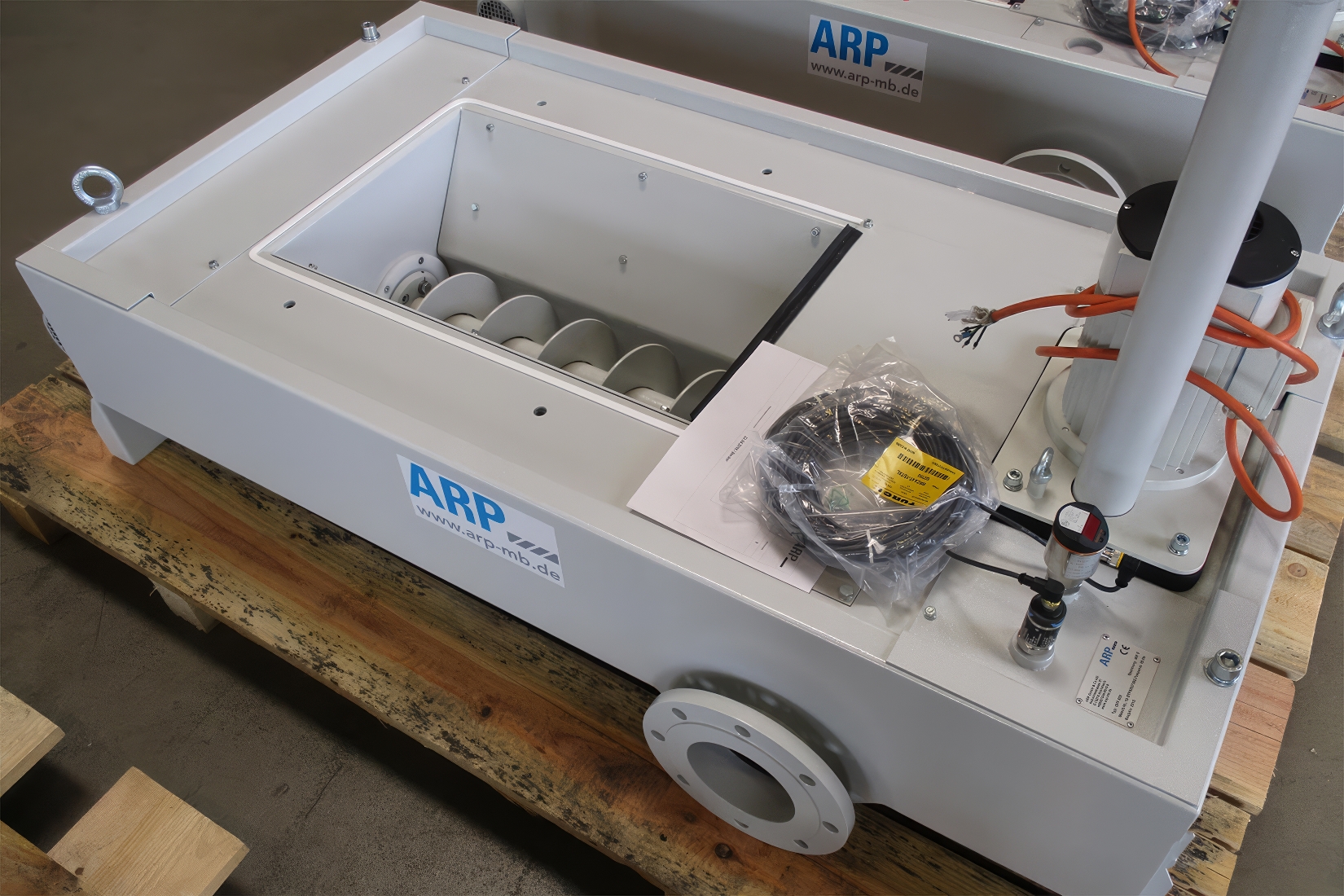

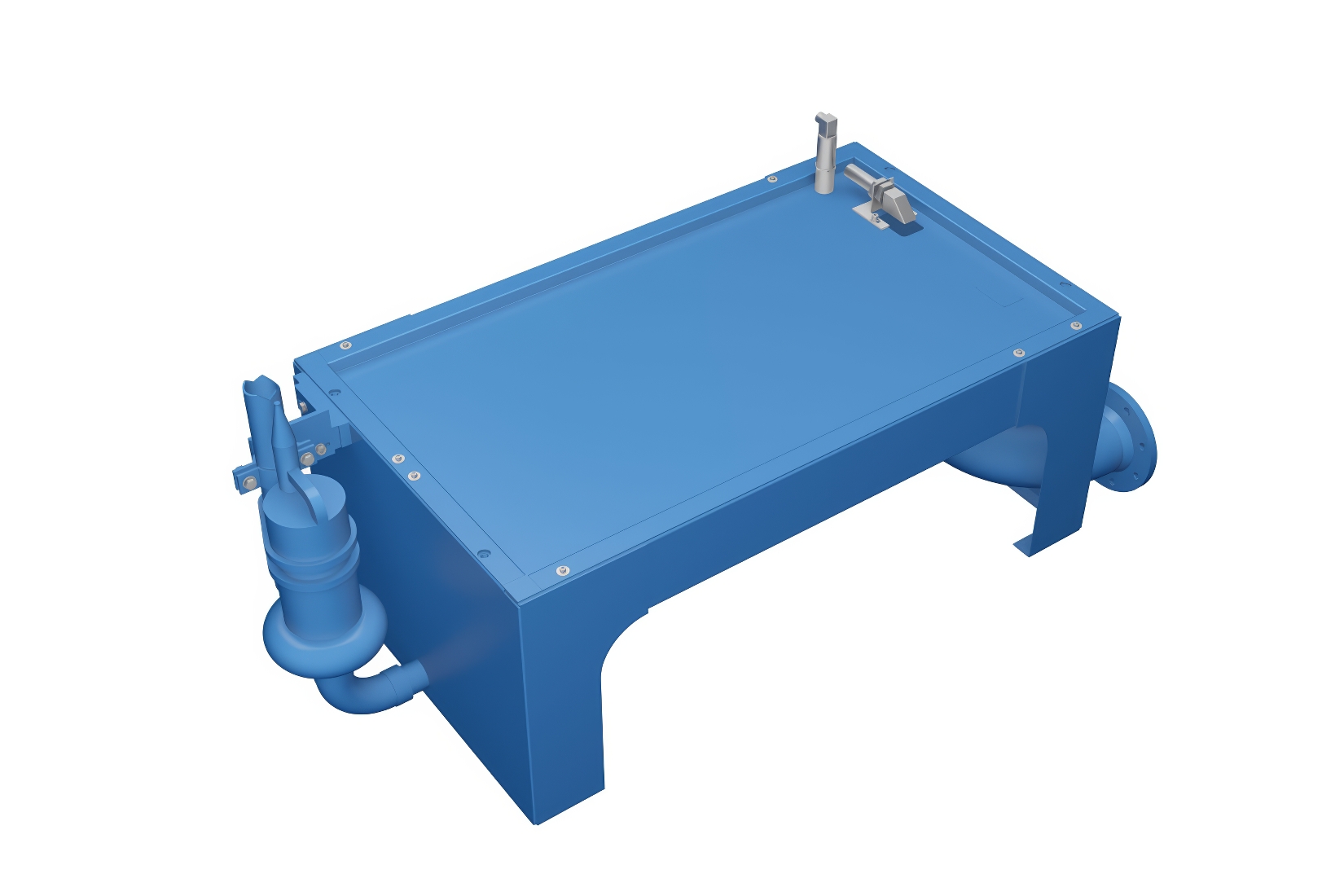

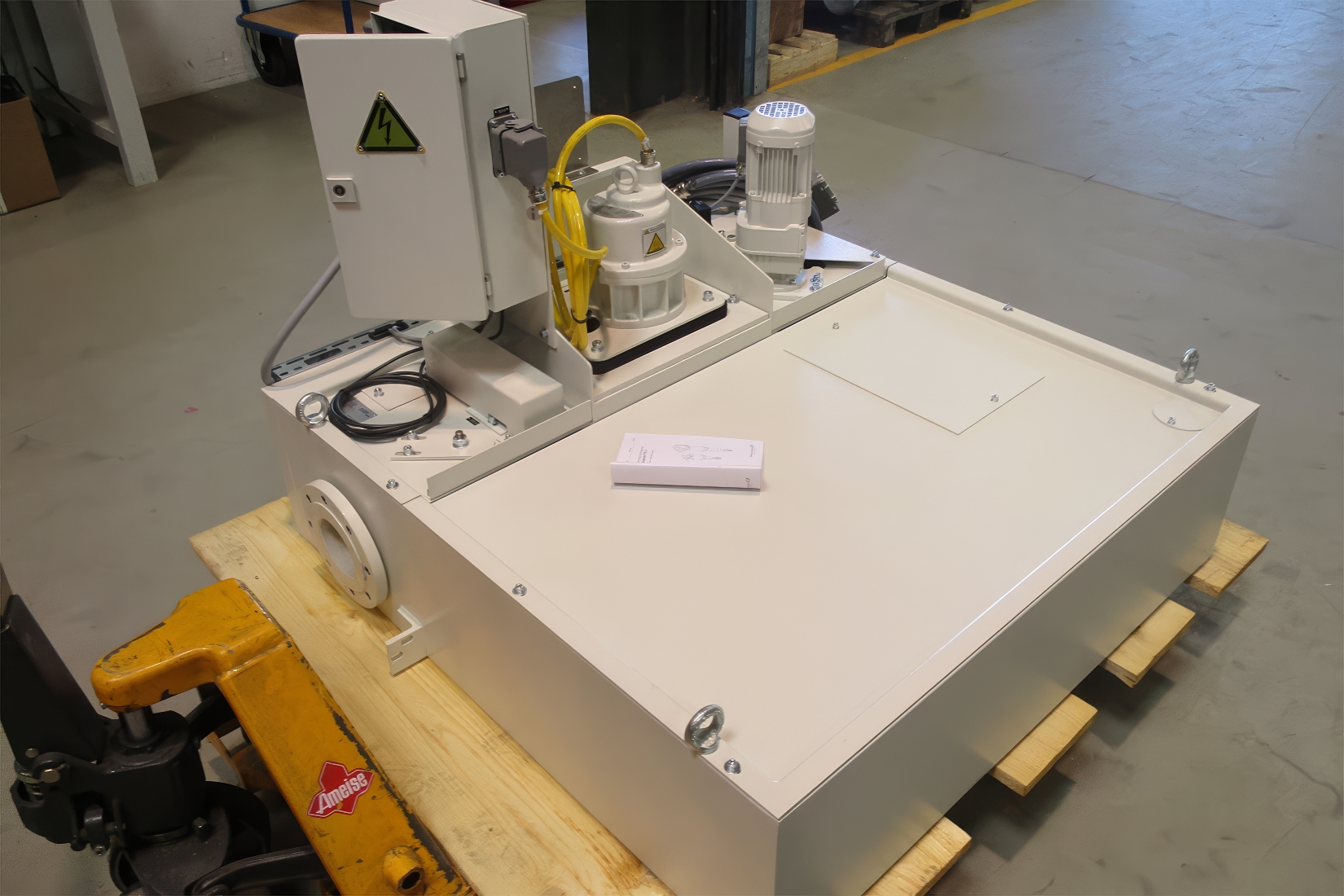

ARP SP & SPF Chip Pumping Stations

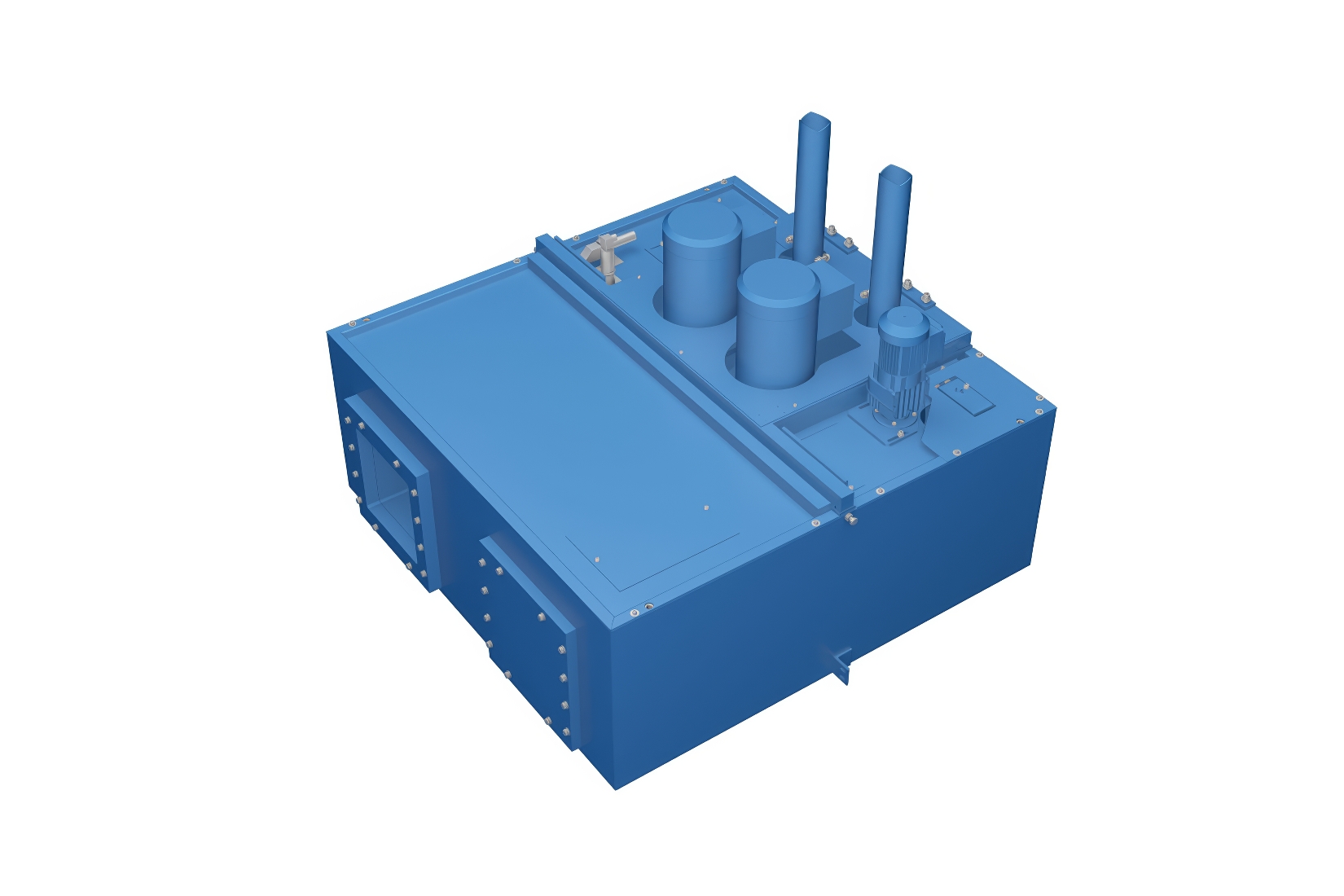

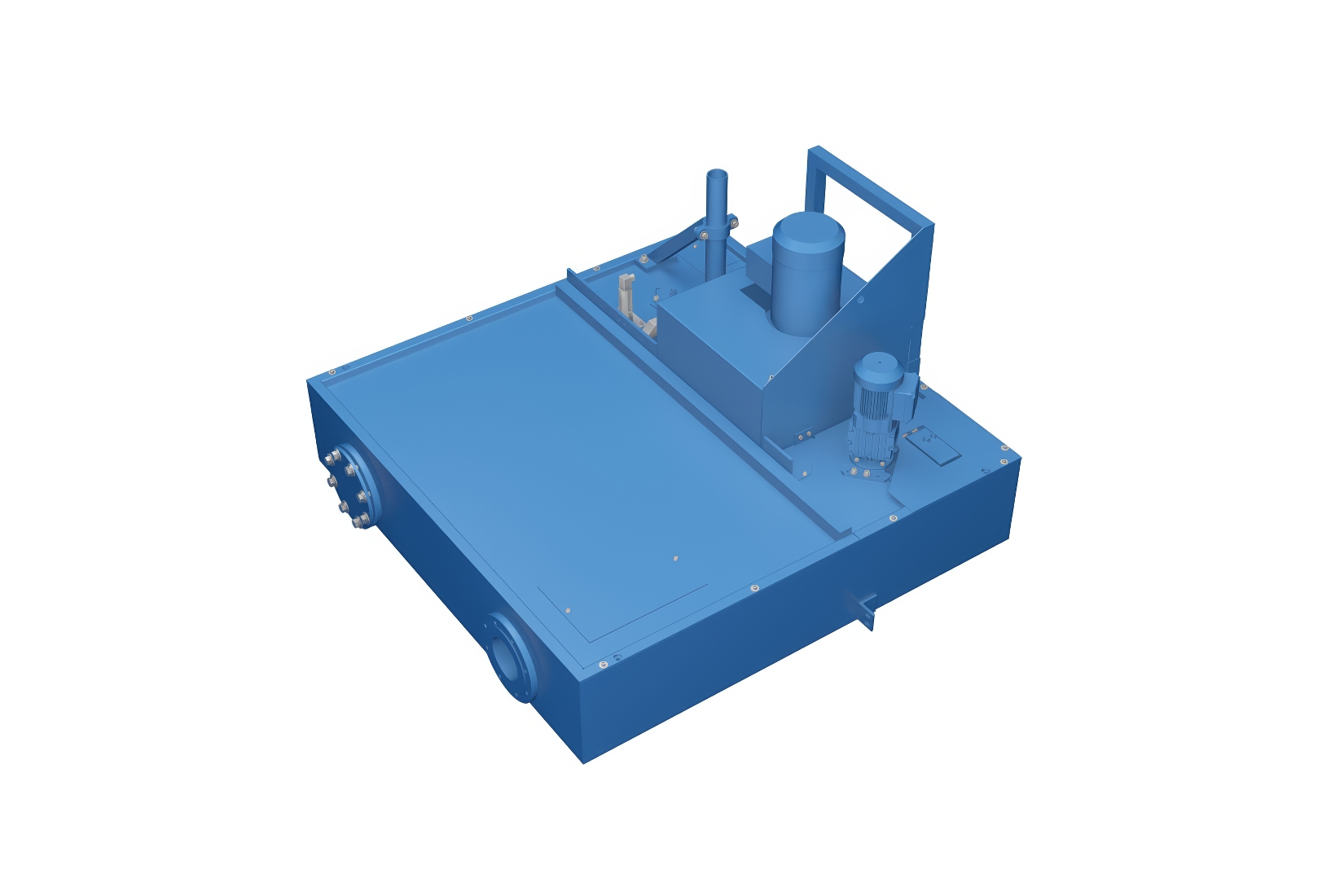

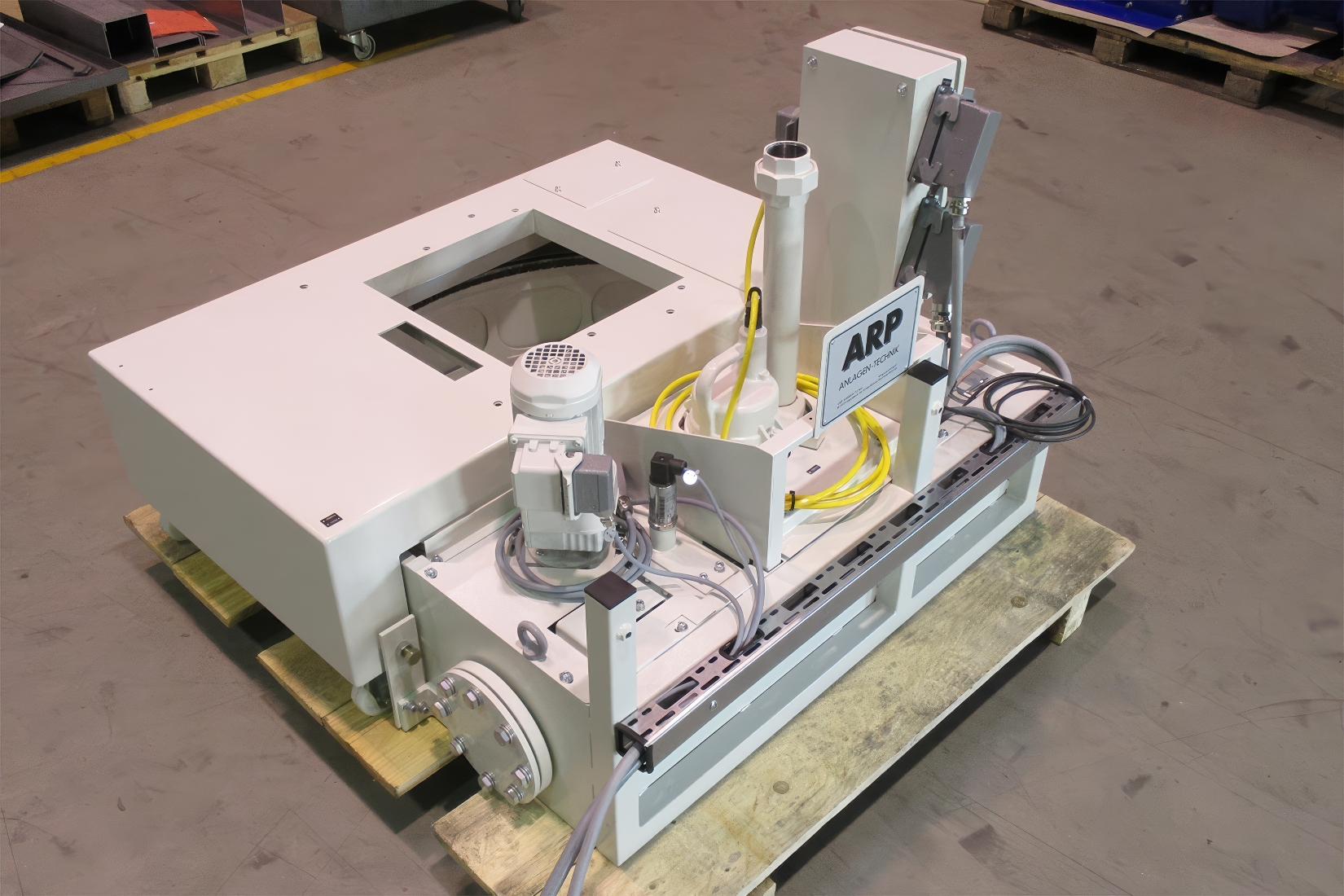

ARP offers a range of individually optimized pumping stations for chip disposal systems and grinding technology, designed for their respective tasks. These pumping stations are extremely reliable and have proven effective in demanding everyday use. The SP series includes models SP 250, SP 500, and SP 1000, with throughput capacities of up to approximately 250 l/min, 500 l/min, and 1,000 l/min, respectively. Each model features a robust pump and raker system, with driving powers ranging from 1.5 kW to 5.5 kW for the pump and 0.15 kW for the raker. The inner container sizes are as follows: SP 250 has a diameter of 1,020 mm and a height of 270 mm; SP 500 shares the same inner container dimensions; and SP 1000 has a diameter of 1,346 mm and a height of 545 mm. The shredder opening sizes are variable, up to a maximum of 500 mm x 500 mm for all three models.

The SPF series, comprising models SPF 500, SPF 600, and SPF 1000, offers additional flexibility with integrated screw conveyors and internal pumps. These models provide throughput capacities similar to the SP series, with the SPF 500 and SPF 600 handling up to approximately 500 l/min and the SPF 1000 managing up to 1,000 l/min. The driving power for pumps in this series ranges from 1.5 kW to 5.5 kW, and the screw conveyors are powered by 0.25 kW drives. The container sizes are as follows: SPF 500 : 1,360 mm x 800 mm x 560 mm; SPF 600 measures 1,490 mm x 810 mm x 395 mm; and SPF 1000 is 1,600 mm x 1,000 mm x 800 mm. The shredder opening sizes are variable, with maximum dimensions of 500 mm x 500 mm for SPF 500, 900 mm x 400 mm for SPF 600, and 1,000 mm x 600 mm for SPF 1000. The compact design and varying dimensions of the SPF models make them suitable for installations with space constraints, while maintaining high performance in chip disposal and grinding applications.

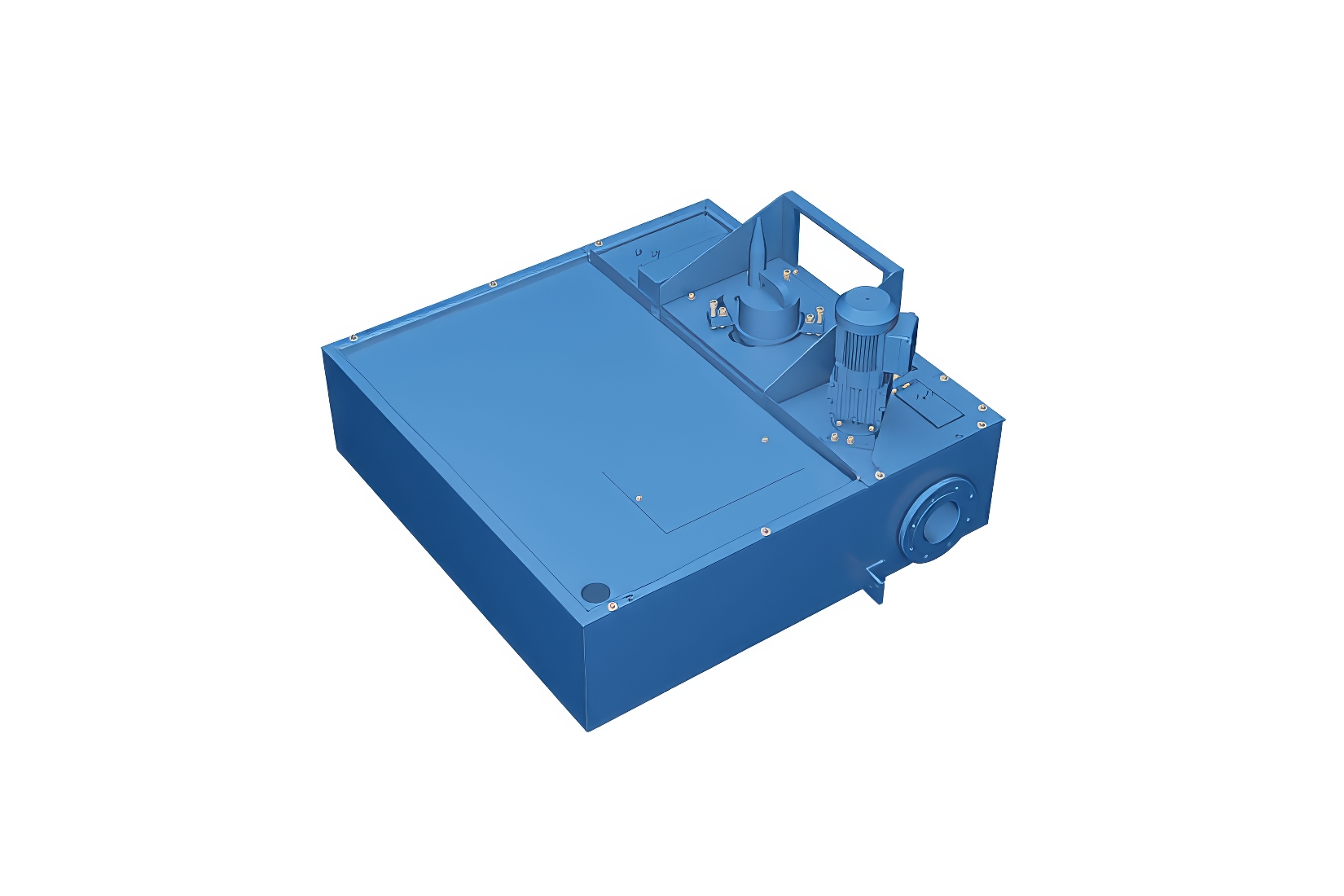

LANNER Briquetting Presses

LANNER‘s briquetting presses are engineered to compact metal chips and grinding sludge into high-density briquettes, enhancing material handling and recycling efficiency. Their compact, robust design ensures quick installation and reliable operation, delivering consistent briquette quality with minimal noise. By significantly reducing the volume of metal waste, these presses lower storage and transportation costs. The high compression achieved increases material value and recovers residual coolants, contributing to resource conservation.

The briquetting process involves feeding coolant-laden chips into the hopper, where a dosing screw continuously supplies them in precise amounts to the pressing chamber. A high-pressure cylinder then compresses the chips into solid briquettes, extracting the coolant in the process. For handling long or tangled chips, an optional integrated chip crusher with a tramp metal ejector is available, ensuring smooth operation and preventing equipment damage.