Pre-separation and Dry Filtration OMAR -Dry Filters

PRE-SEPARATION AND DRY FILTRATION

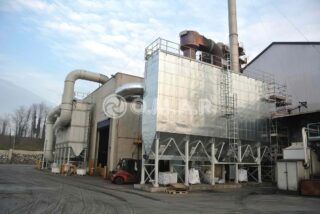

Self-cleaning Modular Bag Filters with Panels | OMAR PJ

Self-cleaning Bag Filters for High-Temperature Smoke & Gas | OMAR PJt

Self-cleaning Bag Filters, Cell Filters & Special Filters | OMAR PJs

Vertical and Horizontal Cartridge Filters | OMAR CF

Static Panel Filters – Pockets (Demister) | OMAR SPF

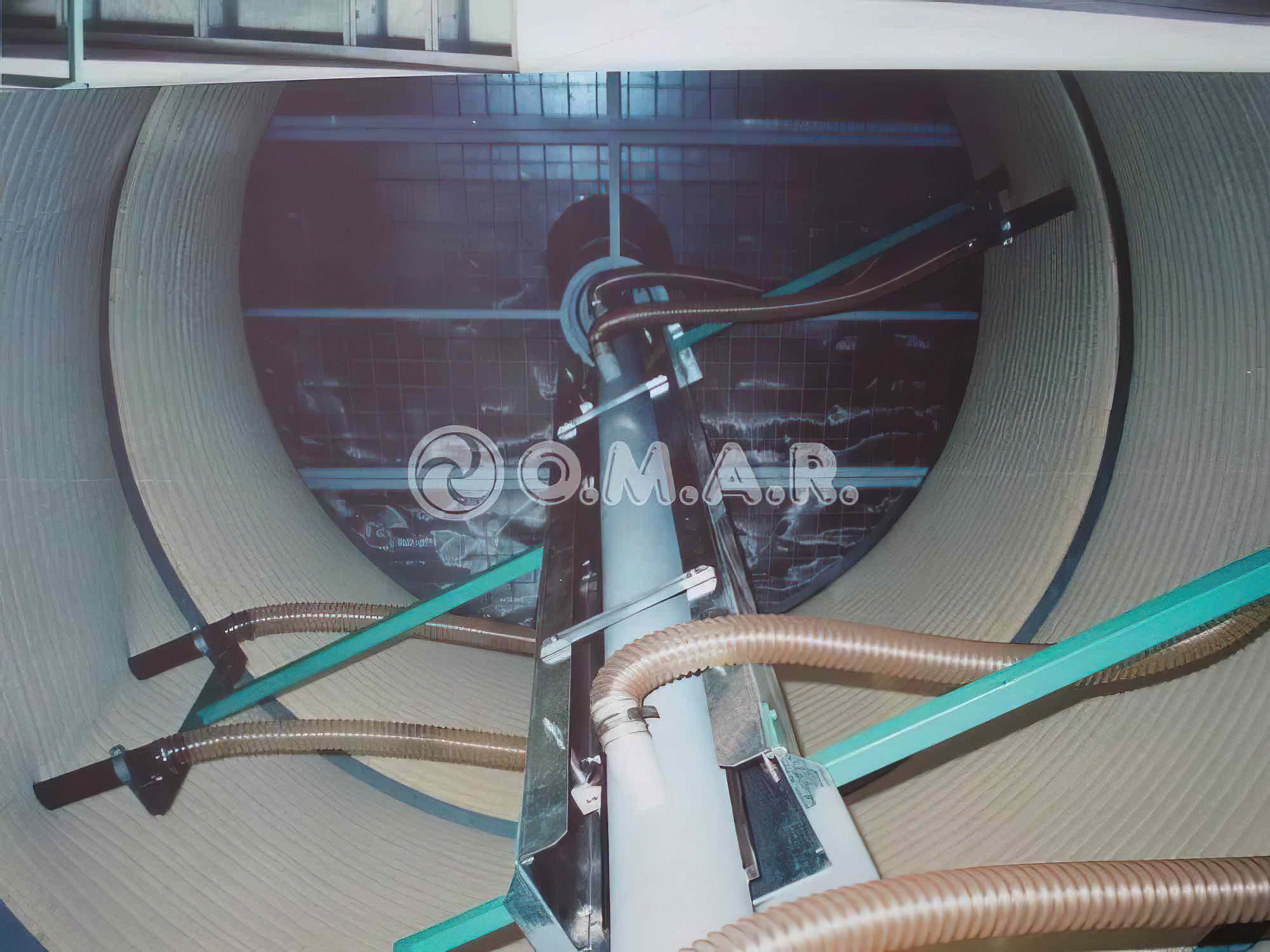

Industrial Rotary (HV) Filters | OMAR IRF

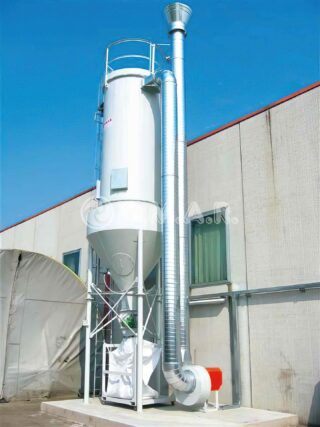

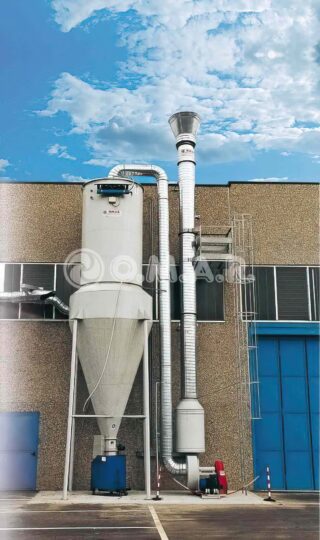

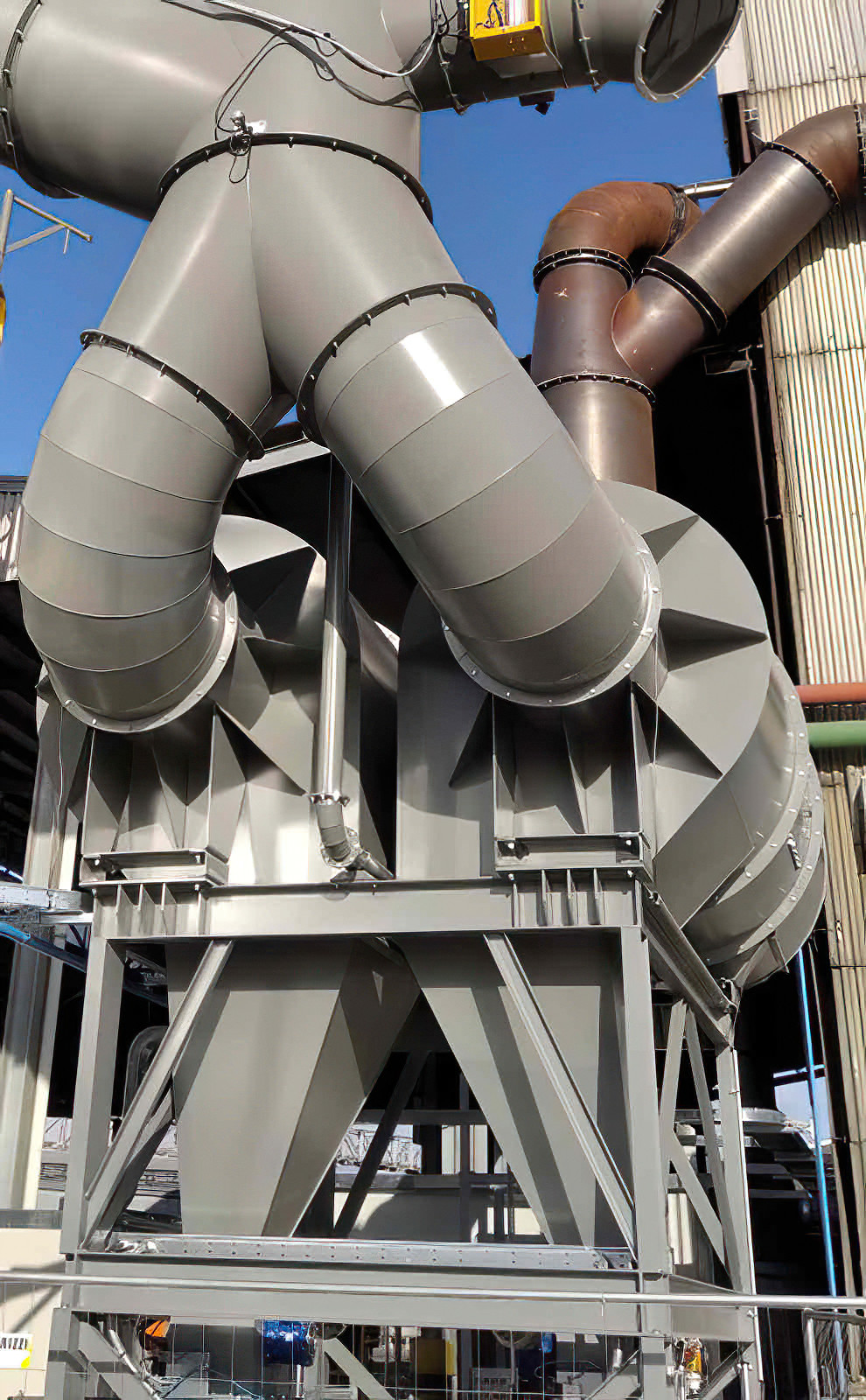

Self-cleaning Bag Filter Cyclones | OMAR BFC

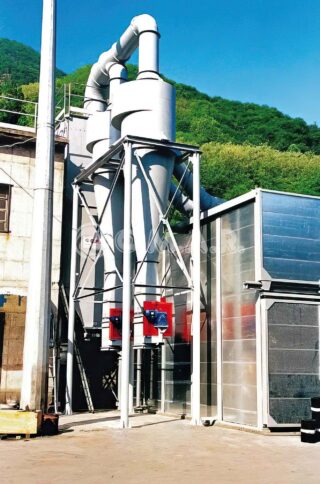

Pre-separator Cyclones | OMAR PsC

Multicyclones | OMAR MC

Static Spark Separators| OMAR SSS

Static Aeraulic Separators | OMAR SAS

Rotary Aeraulic Separators | OMAR RAS

Activated Carbon Filter | OMAR ACF