Depackers and Bale Breakers

DEPACKERS AND BALE BREAKERS

Depacker Systems – TECNOFER

TECNOFER offers a range of advanced depacker systems designed to efficiently separate packaged waste into recoverable contents and recyclable packaging. These systems are tailored for various industries, including food and beverage, pharmaceuticals, and consumer goods, and can handle diverse packaging types such as plastics, aluminium, Tetra Pak and composites. The depackers ensure minimal contamination of both contents and packaging, optimising material recovery while reducing waste disposal costs.

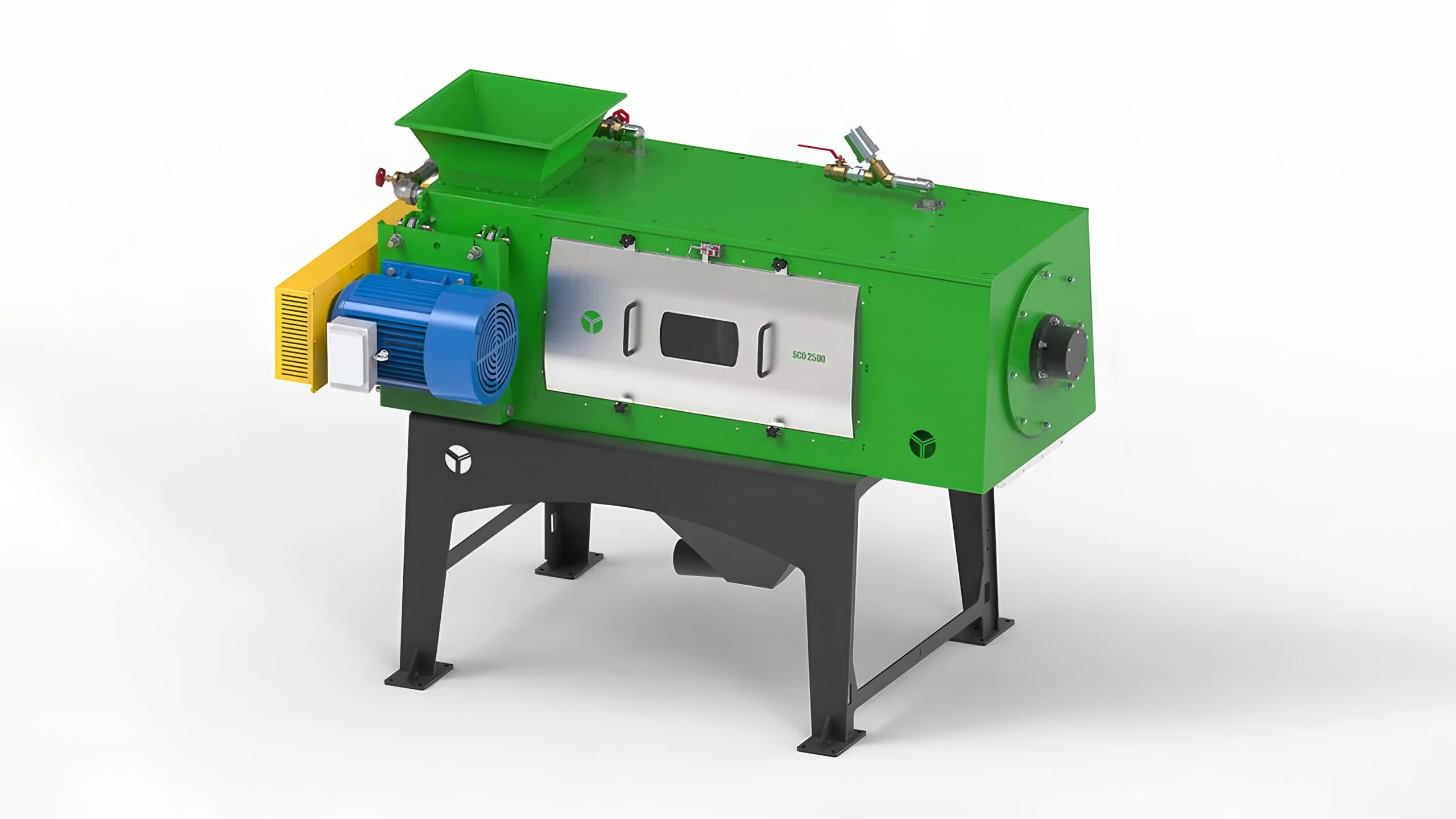

One of TECNOFER’s flagship solutions is the SCO 2000, an all-in-one system designed for high-capacity operations. It employs a high-torque rotary blade mechanism that delicately opens packaging without damaging the contents, ensuring effective separation. The recovered liquids, powders, or pastes are directed to dedicated outlets for storage or reuse, while the packaging materials are sent for recycling. Fully automated and capable of processing mixed waste streams, the SCO 2000 integrates seamlessly into existing recycling lines, delivering precision and efficiency for large-scale operations.

In addition to the SCO 2000, TECNOFER offers other depacker solutions to address specific waste separation needs. These include systems for processing expired products, damaged goods, and post-consumer waste, with configurations optimised for varying throughput requirements and material types. Each depacker is constructed with robust materials to withstand the demands of continuous use, ensuring long-term reliability and low maintenance. TECNOFER’s depackers are indispensable for industries aiming to achieve high recovery rates, sustainability goals, and operational efficiency in modern recycling workflows.

New Depacker | SCO 2000D

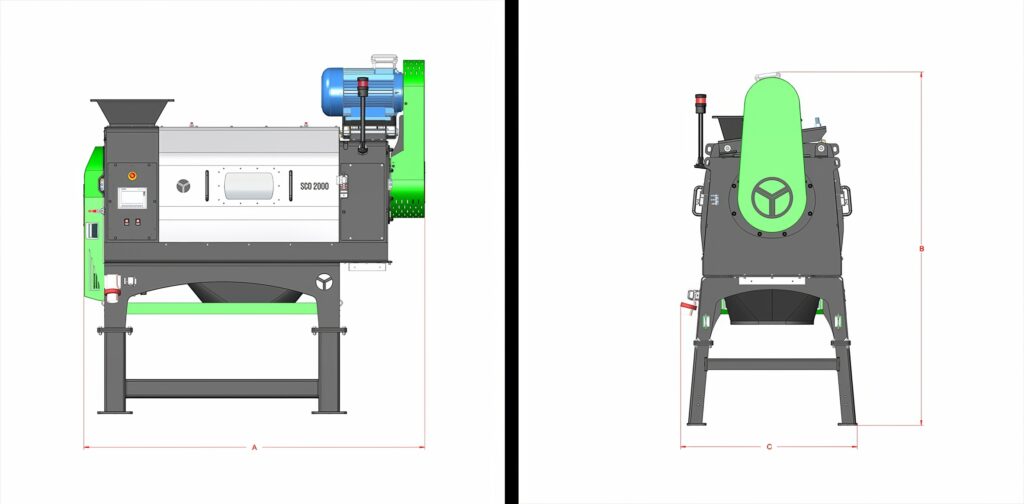

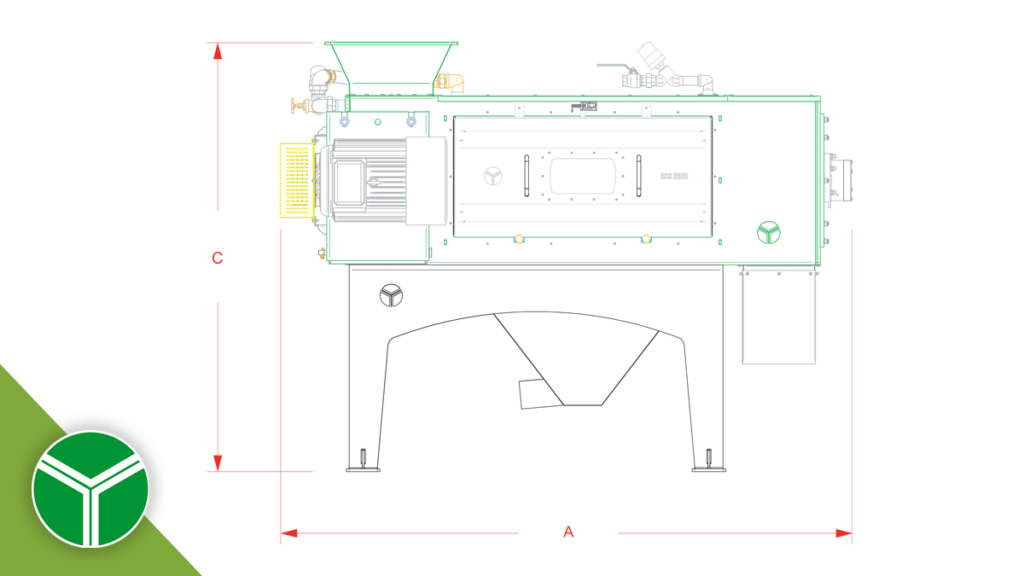

TECNOFER’s SCO 2000D is a depackaging machine: a one-step solution designed to combine high depackaging performance with smart features for operator and corporate process management.

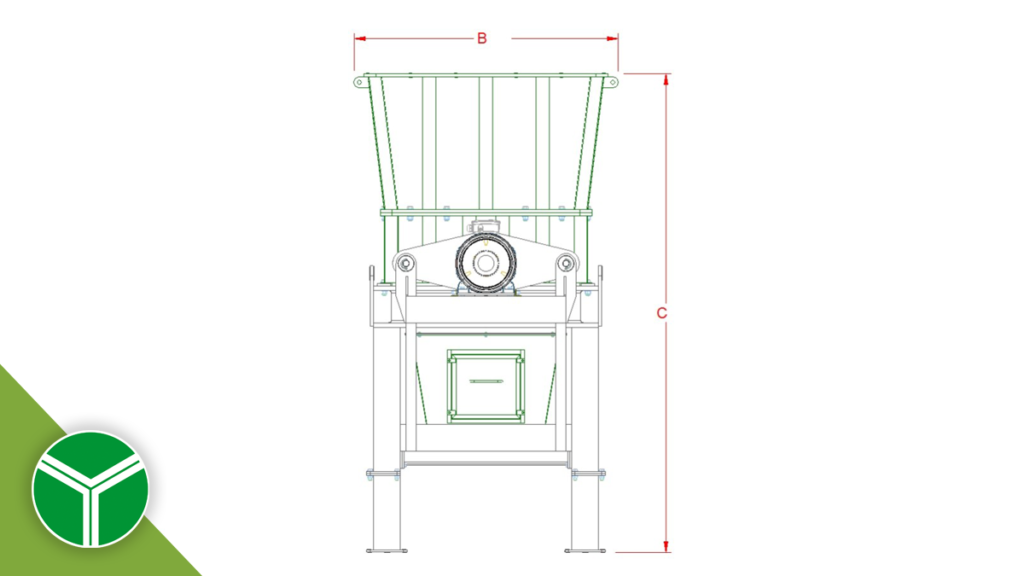

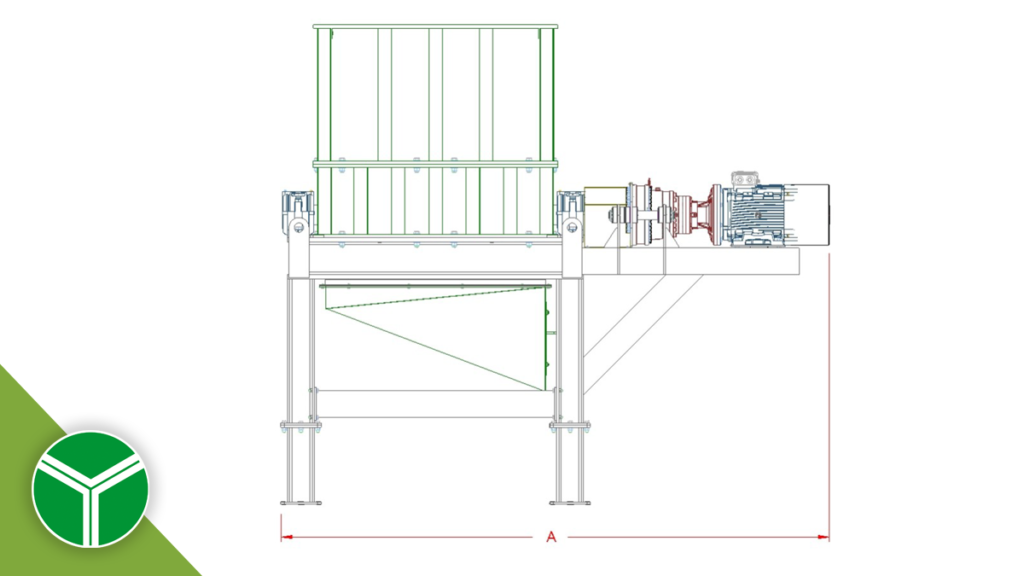

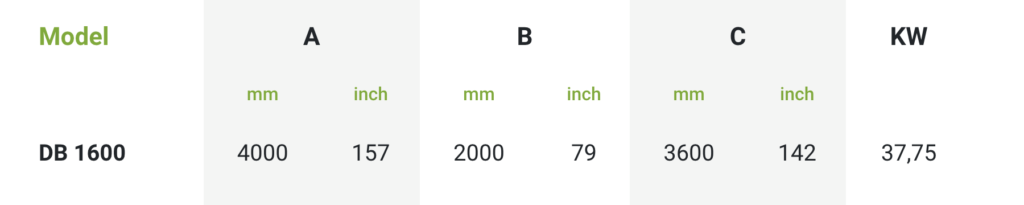

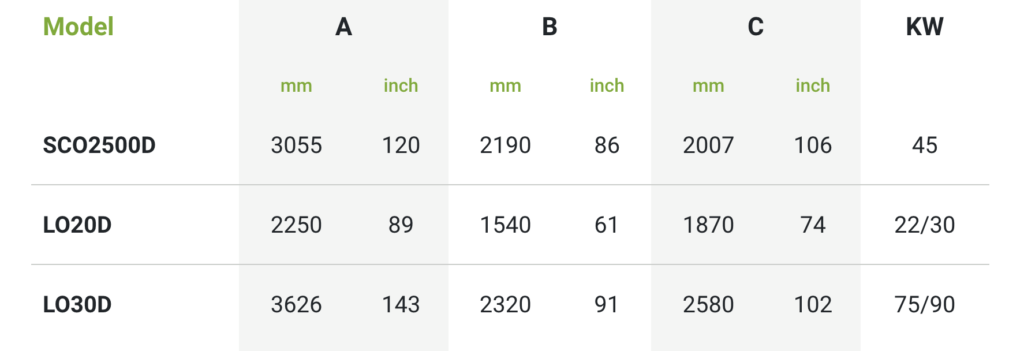

Drawing | Dimensions & Capacities

Bale Breaker – TECNOFER

TECNOFER’s Bale Breaker is a robust system designed to efficiently loosen and separate compressed bales of plastic materials, such as PET bottles, films, and other recyclables, preparing them for downstream recycling processes. This machine ensures smooth and continuous feeding of materials into subsequent equipment like washing systems, shredders, or sorting lines, optimising the efficiency of the entire recycling workflow. The Bale Breaker operates using rotating shafts equipped with blades or paddles that gently tear apart the compressed bales without damaging the individual plastic items. This ensures that the materials remain intact for effective cleaning, sorting, or processing in the next stages. The system is highly versatile and capable of handling bales of varying sizes and densities, accommodating a wide range of plastic waste streams.

Built with durable materials and engineered for long-term reliability, the Bale Breaker is ideal for recycling facilities handling large volumes of baled plastics. Its integration into recycling lines ensures consistent material flow, minimises blockages, and reduces manual labour requirements. By delivering uniform and well-separated materials, TECNOFER’s Bale Breaker enhances the efficiency and quality of plastic recycling operations.

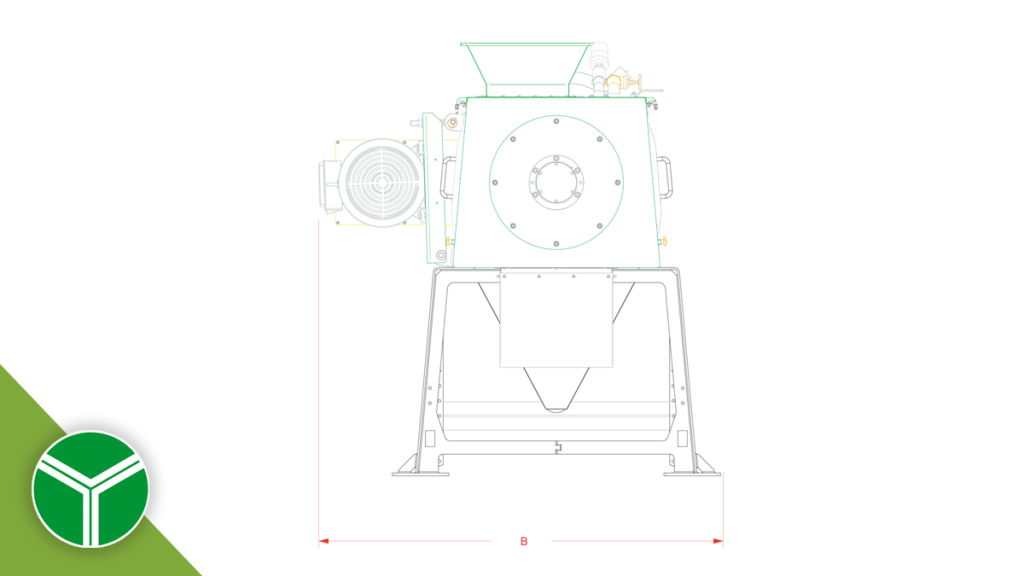

Drawing | Dimensions & Capacities