Single-Shaft Shredding Machines

SHREDDERS

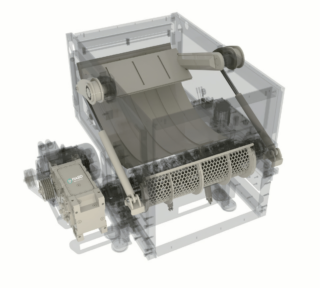

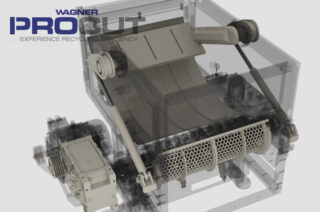

Single Shaft Shredding Machines – WAGNER PROCUT

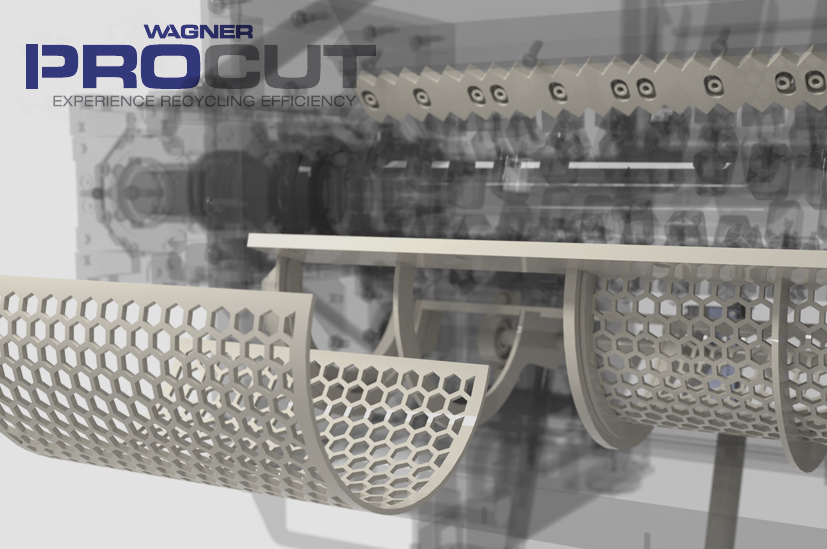

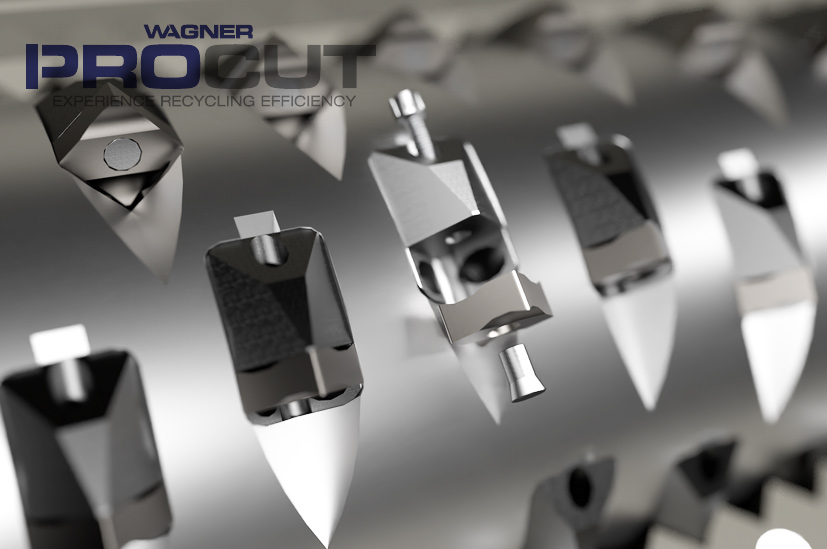

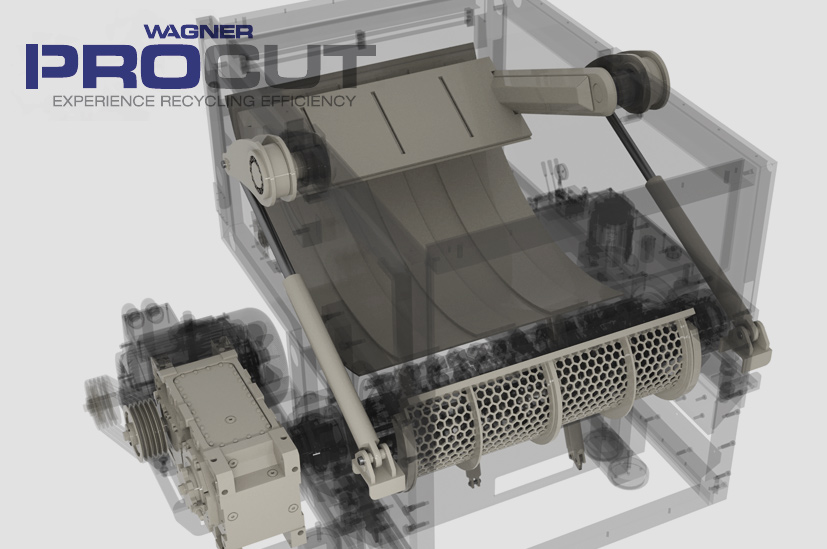

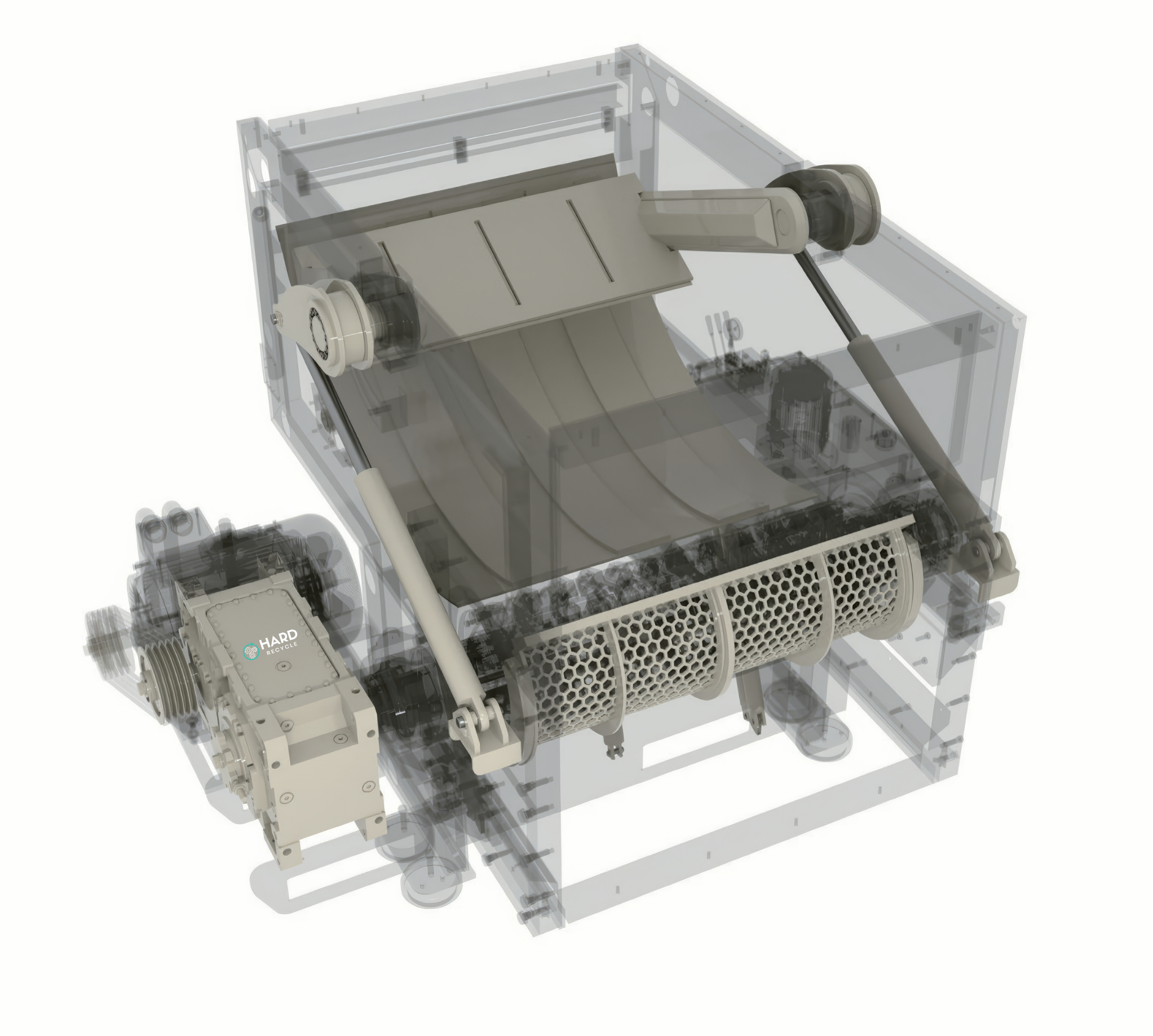

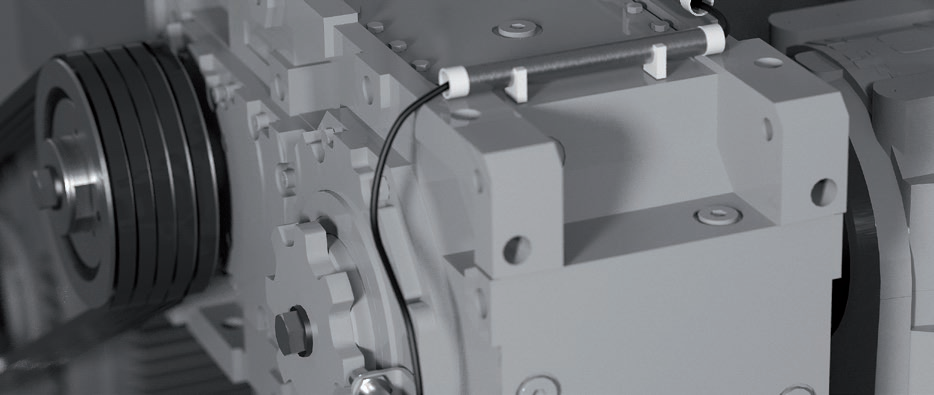

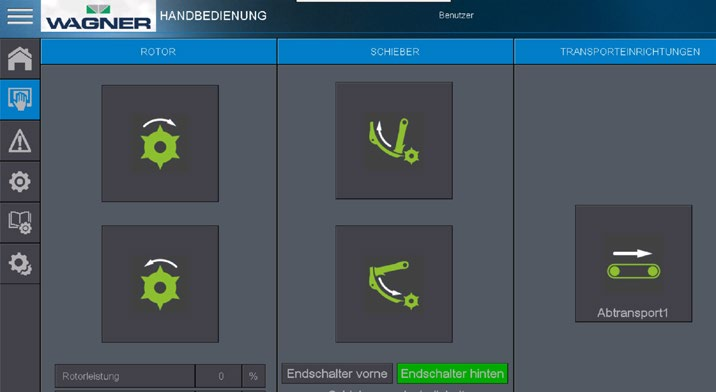

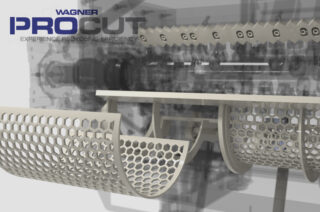

The WAGNER PROCUT range of universal single-shaft shredders, including the PROCUT 1300, 1600, and 1900 models, represents the pinnacle of efficiency, durability, and flexibility in the recycling and waste management industry. Engineered to deliver high performance, these shredders feature precision cutting rotors with tight manufacturing tolerances, optimised knife arrangements for increased throughput, and optional rotor cooling for processing meltable materials. With robust designs and field-proven heavy-duty gearboxes, they ensure long service life and peak reliability.

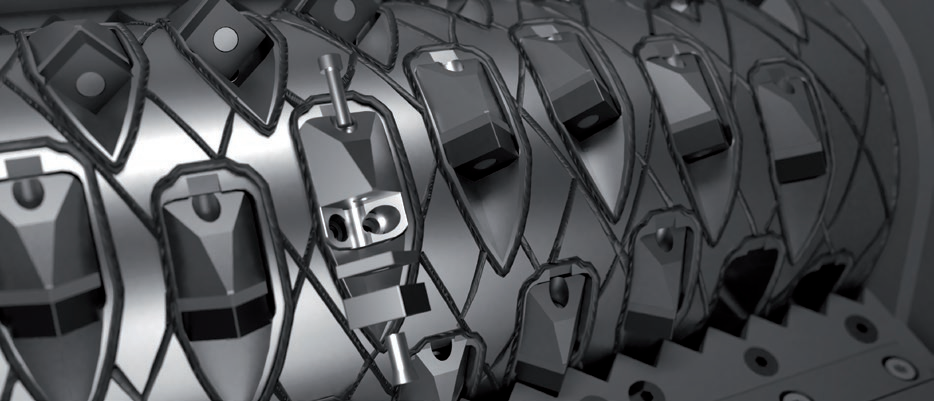

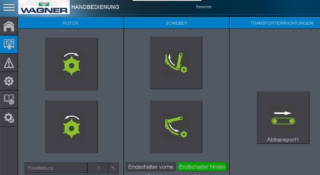

Tailored for versatility, the Procut shredders offer adjustable knife systems made from high-quality tool steel or carbide, allowing for eight-fold knife use and quick replacement to minimise downtime. Equipped with sensor-monitored hydraulic swing pushers and hydraulically operated HARDOX® screen baskets, they adapt seamlessly to diverse materials and output requirements. Their innovative control panels enable precise power management, multiple working programs, and remote maintenance. With a focus on energy efficiency, low maintenance, and intelligent technology, the Procut range sets new standards for sustainable and effective material processing.

Single Shaft Shredding Machines – WAGNER WS Series

The WAGNER WS series of universal single-shaft shredders represents a versatile and robust solution for a wide range of material processing needs. From the compact WS 5 to the industrial-scale WS 50 and WS 70, these shredders are designed for handling diverse materials such as plastics (hard and soft), wood, paper, textiles, foam, electric cables, and more. Their adaptability makes them ideal for applications across industries, including waste management, recycling, and material preparation.

Each model in the WS series features a cutting rotor equipped with wear-resistant knives made from high-quality steel or hard metal, ensuring durability and efficient processing. With innovative knife geometry and precise arrangements, the shredders deliver optimal cutting performance while minimising downtime through quick and easy knife replacements. The advanced drive system, incorporating high-quality European gearboxes and hydraulic shock absorbers, ensures reliable operation with low maintenance requirements. A sophisticated control system offers 10 programmable work settings, precise power adjustments, and options like Soft Start or frequency converters for enhanced energy efficiency. Whether processing smaller loads with the WS 11-15 or tackling industrial-scale tasks with the WS 50 or WS 70, the WS series combines performance, efficiency, and reliability to meet the demands of modern recycling and waste processing operations.

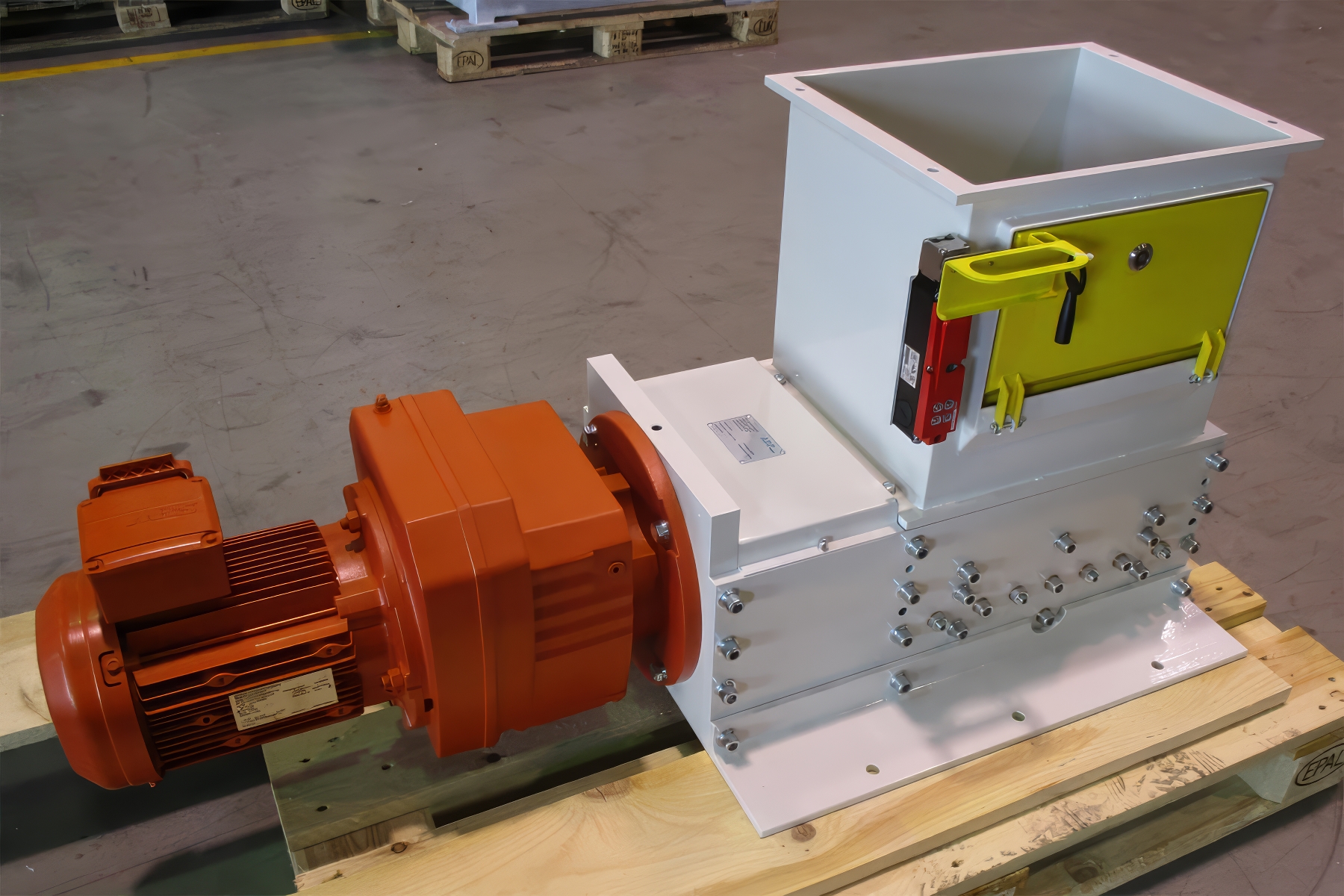

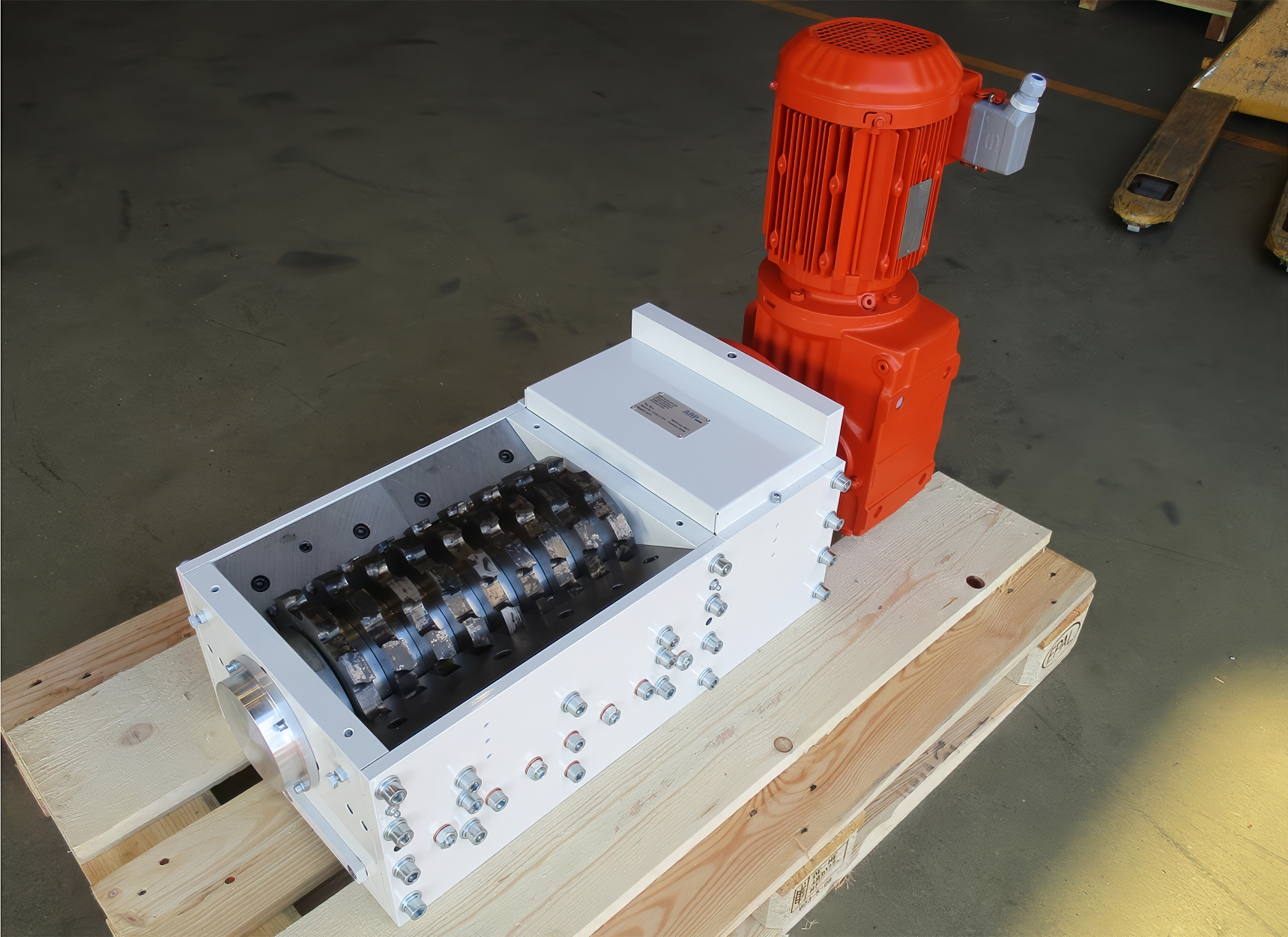

Single Shaft Shredding Machines – TECNOFER Plastic Shredders

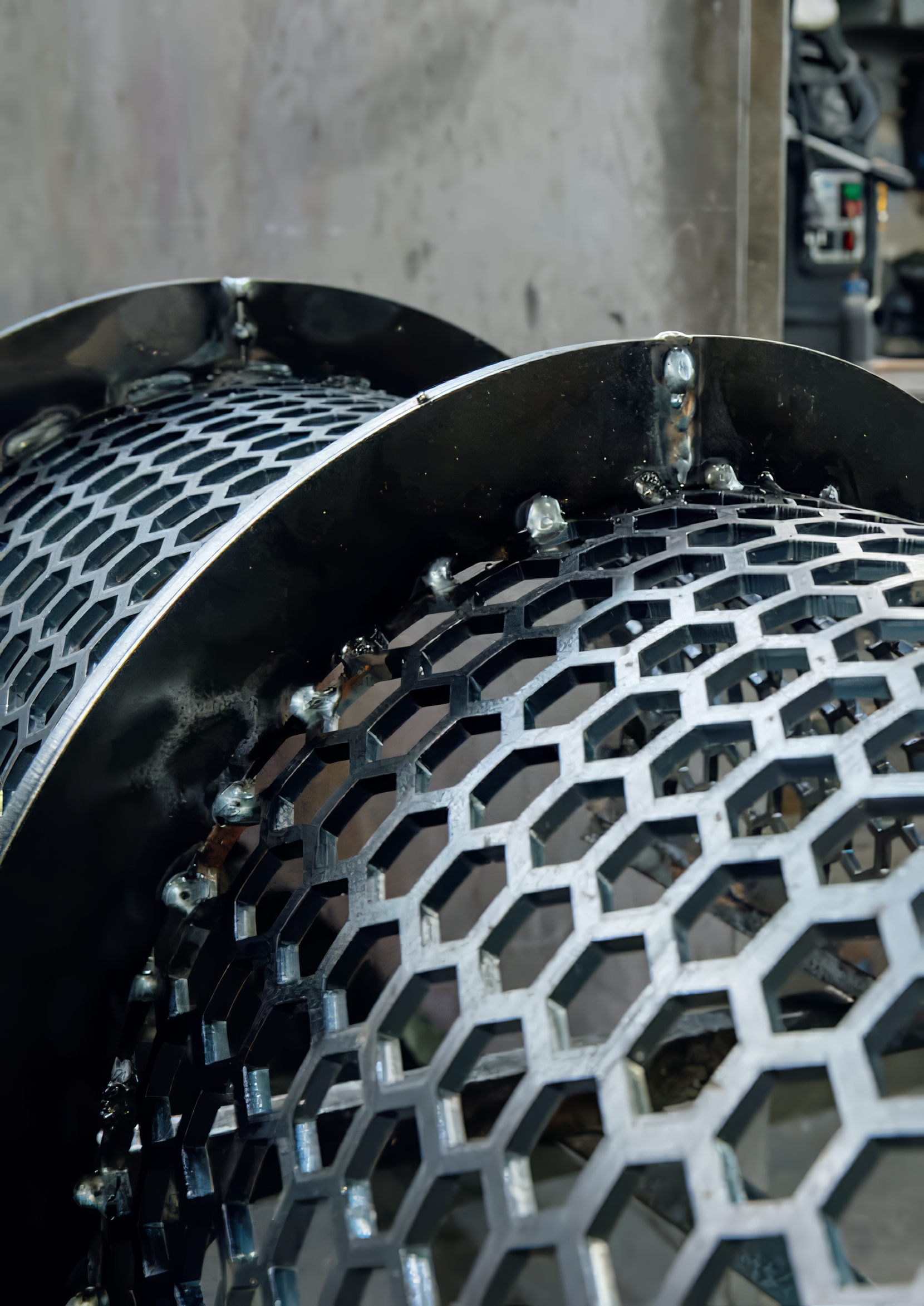

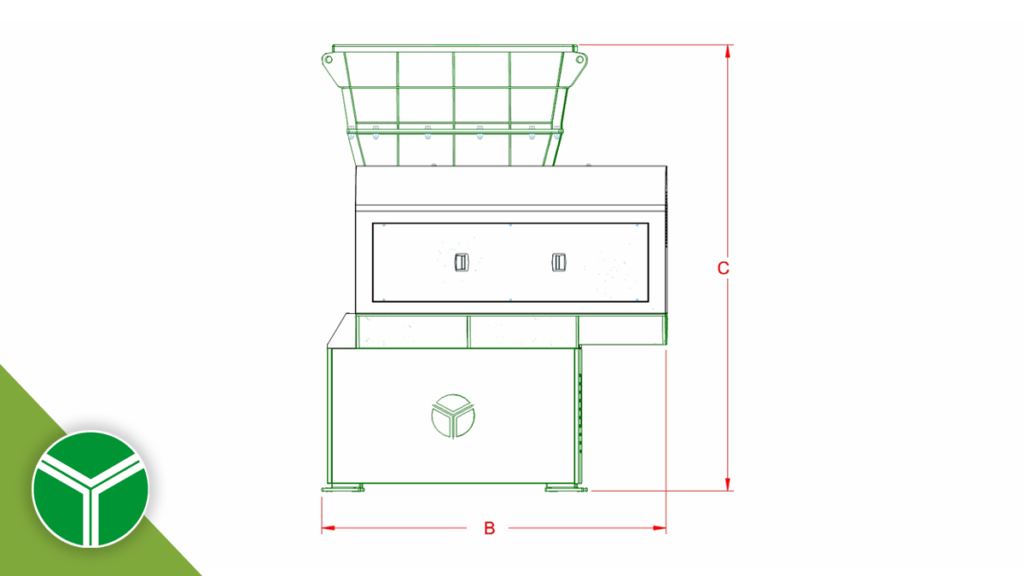

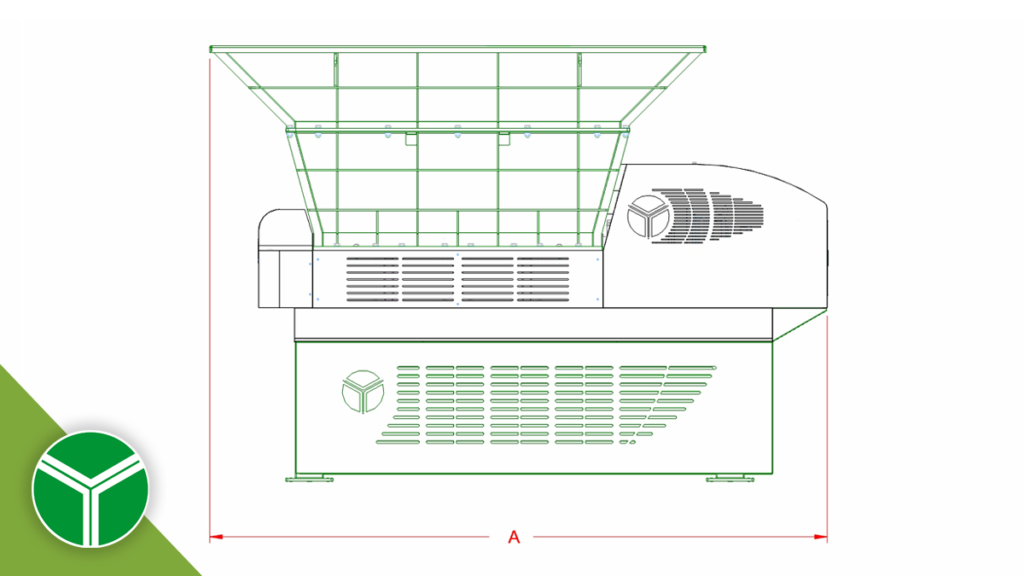

TECNOFER’s Industrial Shredder is a heavy-duty machine engineered for reducing various plastic materials—including films, rigid plastics, pipes, and bulky items—before they enter the washing and recycling phases. Built with a robust steel frame, it can process both light and thick plastic feedstocks, delivering consistent throughput and accommodating diverse input forms such as bales or lumps. A high-torque drive powers a cutting system of rotating blades and fixed counter-blades, which can be adjusted to maintain optimal blade clearances and limit material buildup. The large feeding hopper improves material flow, lowers the risk of blockages, and supports continuous operation. Maintenance and safety measures are incorporated into the shredder’s design through quick-access panels and strategic service points, simplifying blade changes and routine checks. Safety covers, emergency-stop systems, and overload-protection features further protect operators and minimize downtime. The Industrial Shredder can be paired with other TECNOFER machines—like washing tanks and friction washers—to form an integrated plastic recycling line. With various rotor lengths, drive powers, and configurations available, this versatile system accommodates different capacity requirements while providing a reliable, durable solution for effective plastic size reduction.

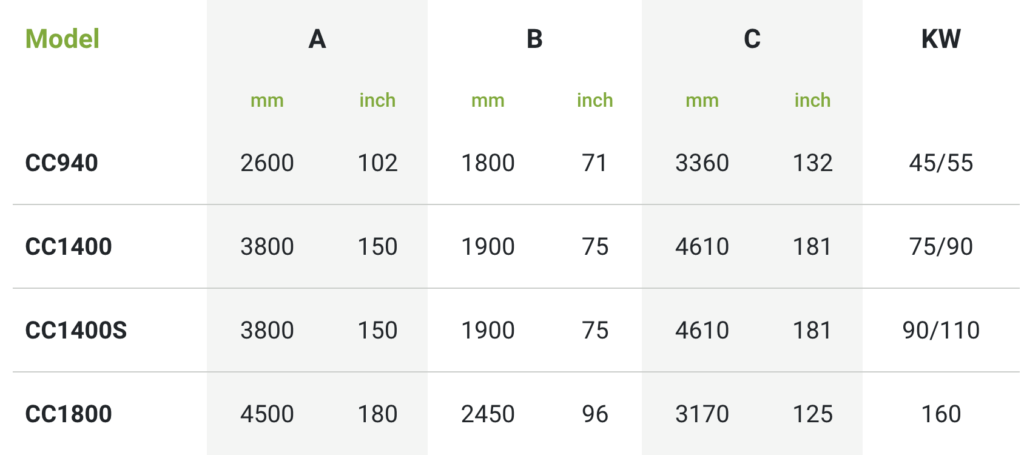

Drawing | Dimensions & Capacities

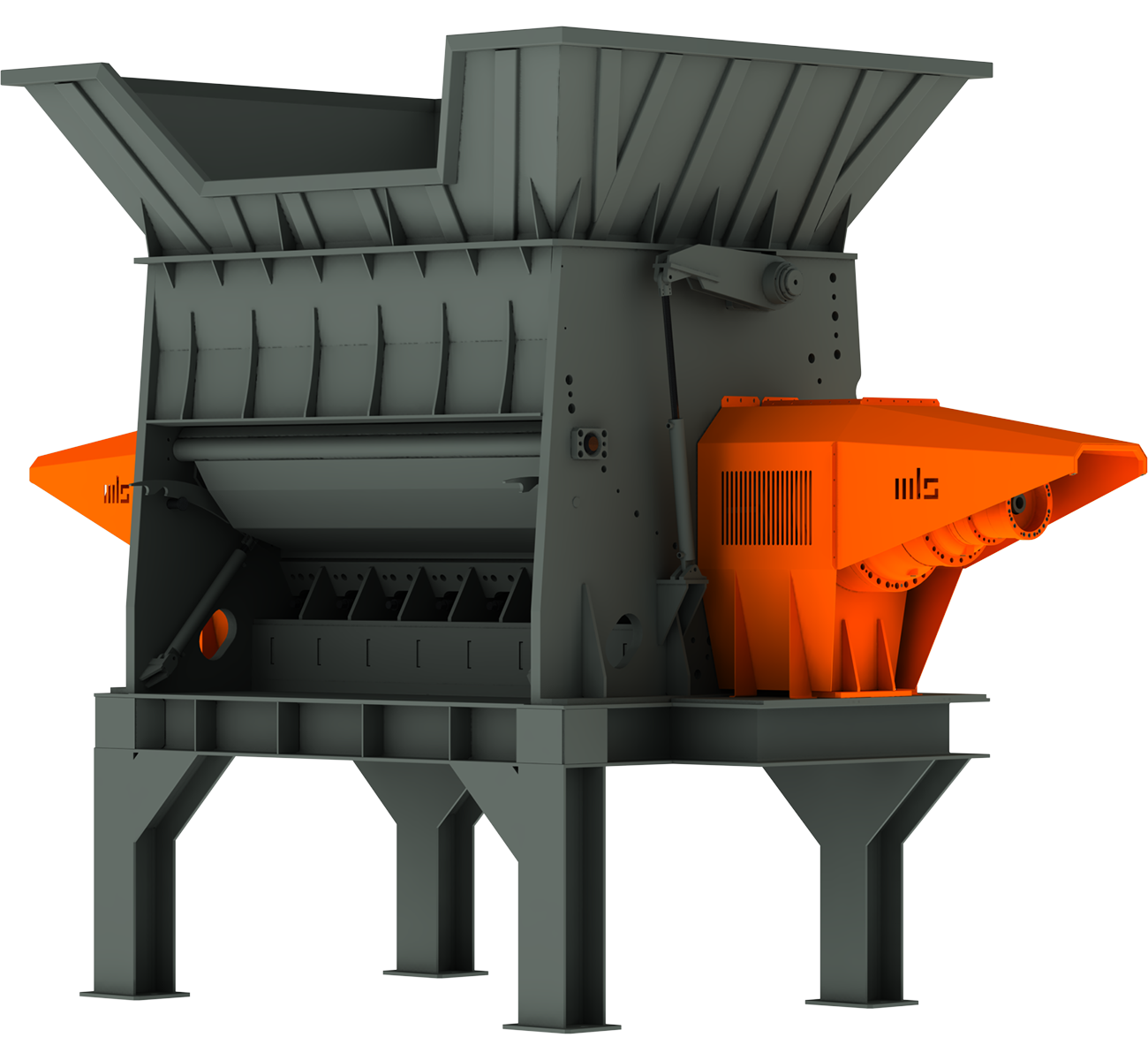

Single Shaft Shredding Machines – MLS Makina

The high-capacity shredder from MLS Makina represents the future recycling technology.

Specifically engineered for sorting materials other than aluminum from scrap, it uses a combination of fixed and movable blades for effective aluminum and metals recycling. Featuring a feed hopper and a specialized rotor, along with blades that are easy to replace, this machine significantly speeds up and streamlines operations. It not only improves waste management and recycling efficiency but also reflects our dedication to conserving natural resources.

MLS Makina introduces this vital piece of equipment to the industry, reinforcing the company’s commitment to sustainability and a cleaner future.