Equipment for Waste & Metal Treatment Separation Systems

SEPARATION SYSTEMS

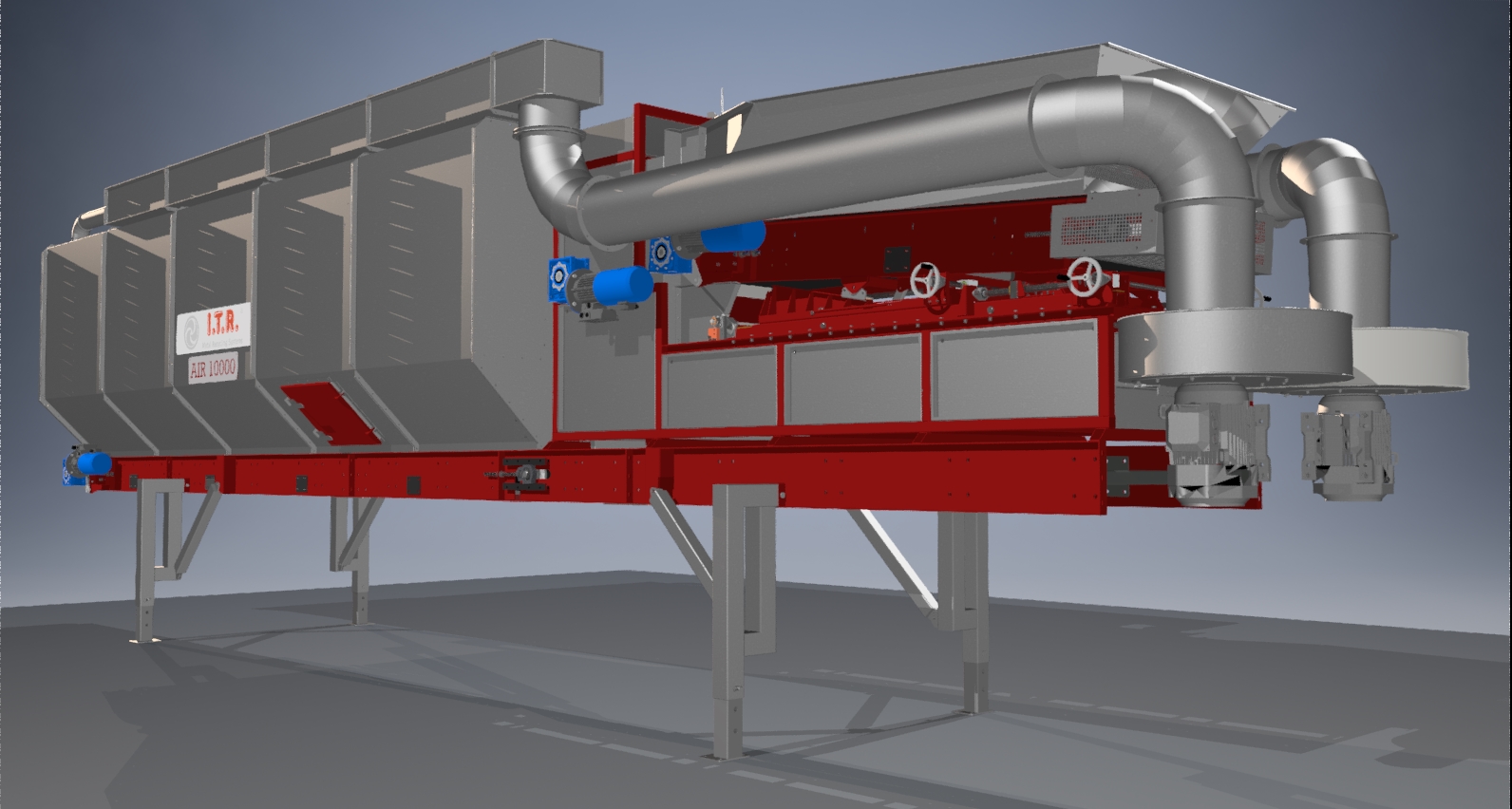

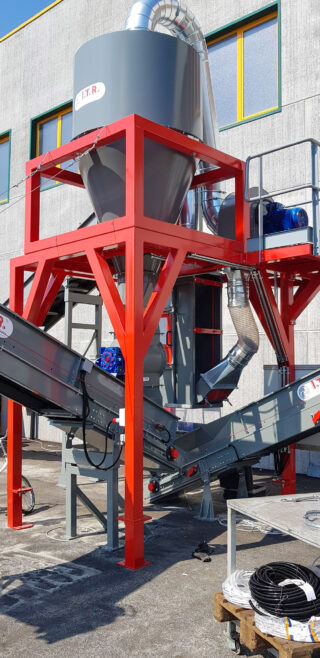

Aeraulic separators | ITR AIR

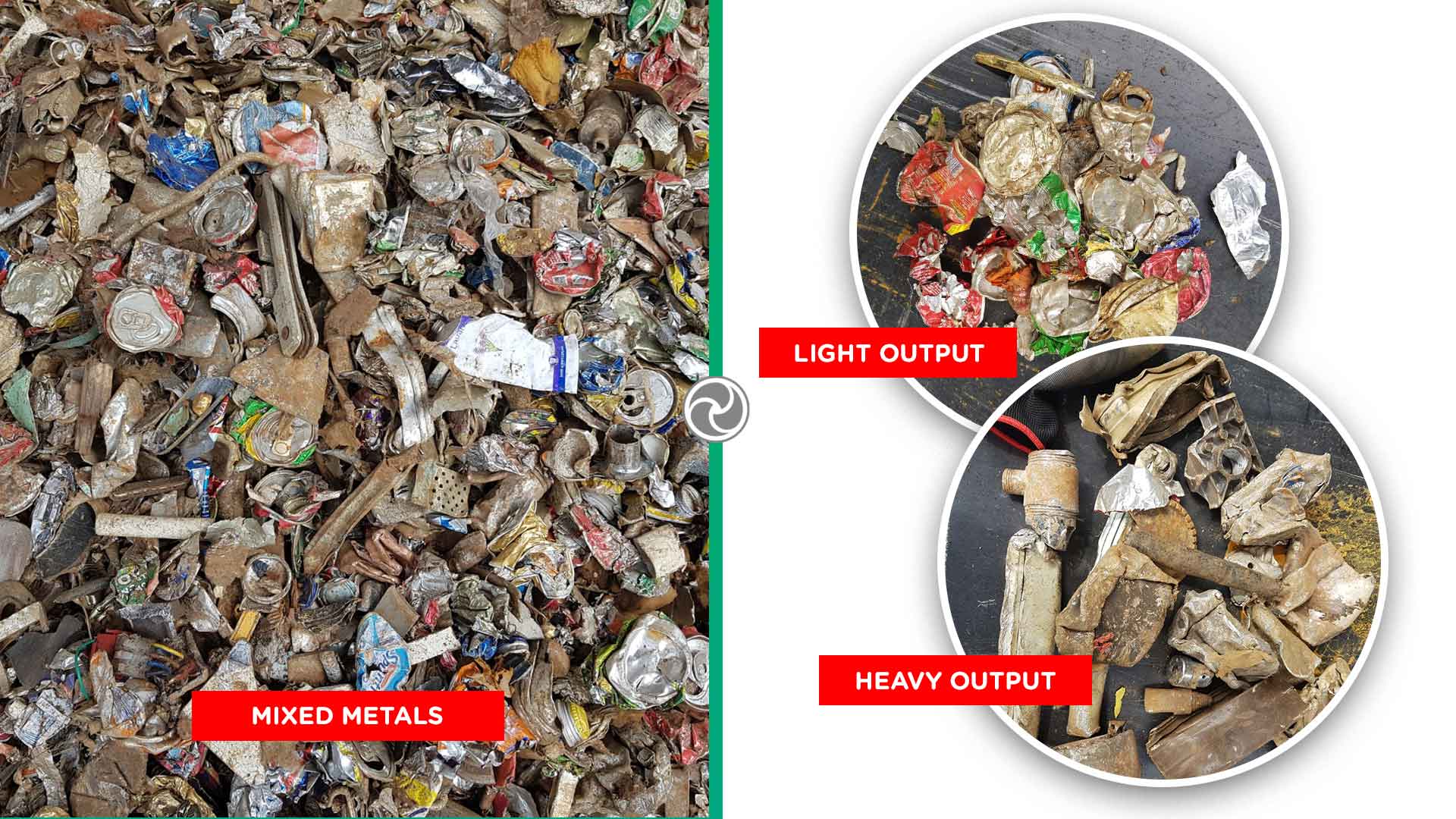

The ITR Recycling System AIR Series Aeraulic Separators are designed to separate and recover light and heavy fractions from pre-shredded or screened waste, including mixed plastics, municipal solid waste (MSW), bulky waste, and mixed metals. Light fractions, such as lightweight plastics, nylon films, paper, wires, and sponges, are separated from heavy fractions like stones, glass, metals, and heavy plastics.

These separators can be integrated into existing plants between primary shredders and secondary grinders, reducing maintenance costs, minimizing machine downtime, resolving separation challenges for metals of varying densities, and improving the recovery and economic value of materials such as aluminum and heavy plastics.

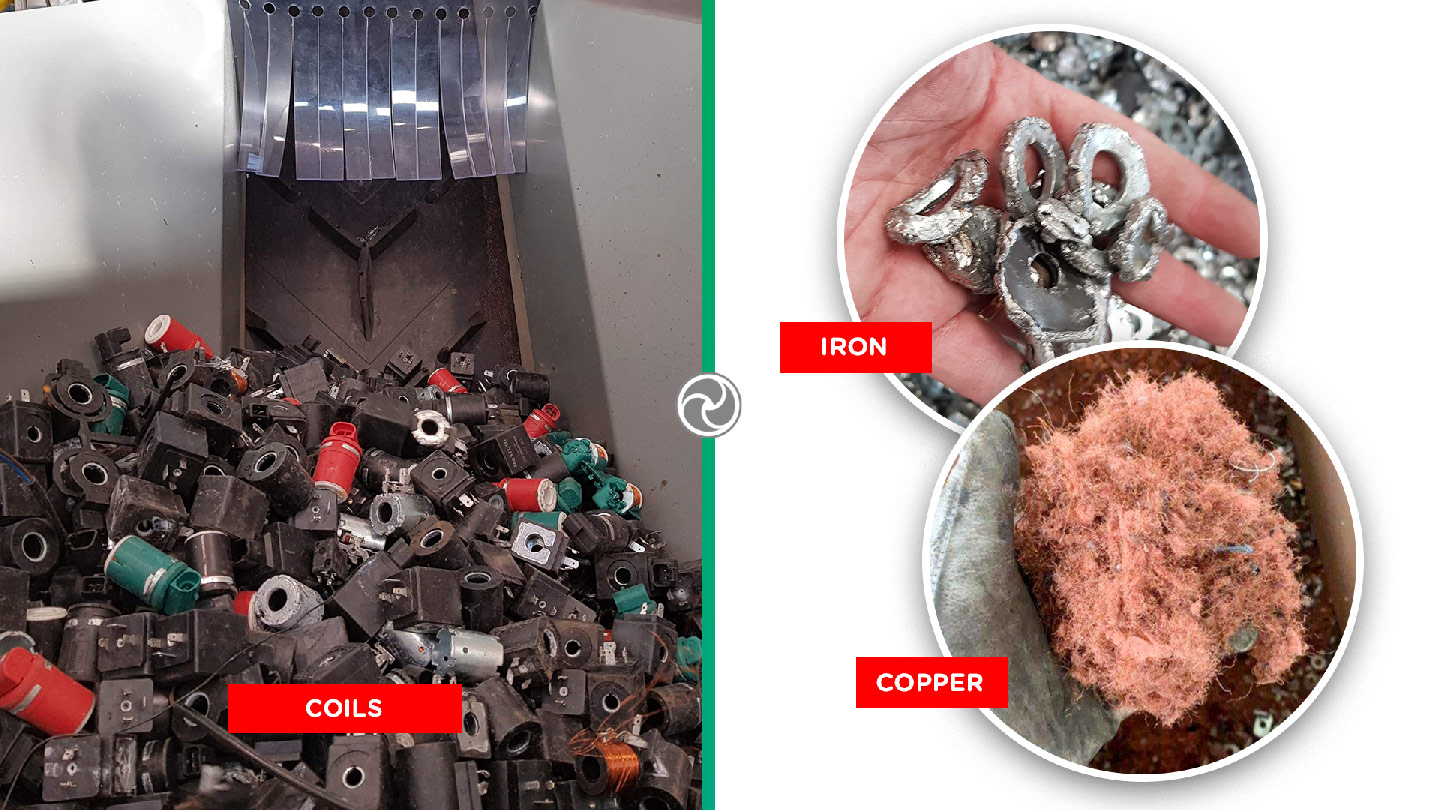

Eddy Current Separators| ITR ECS

Air separation systems | ITR SZZ

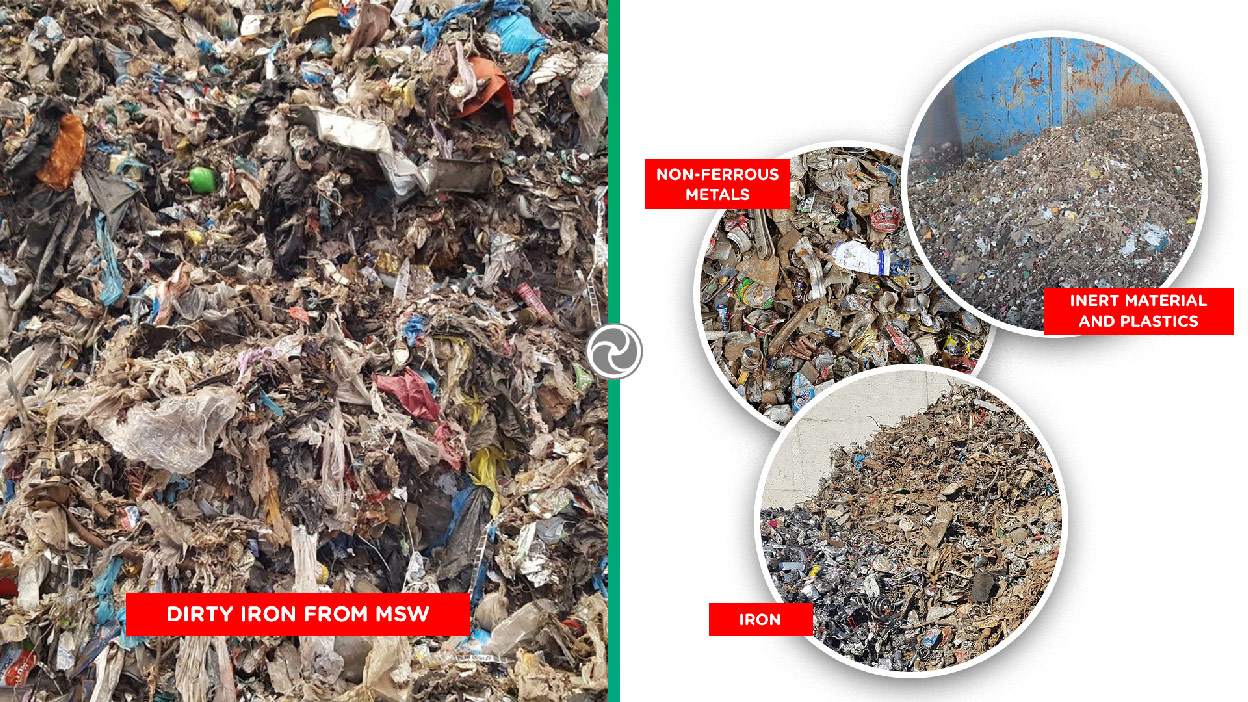

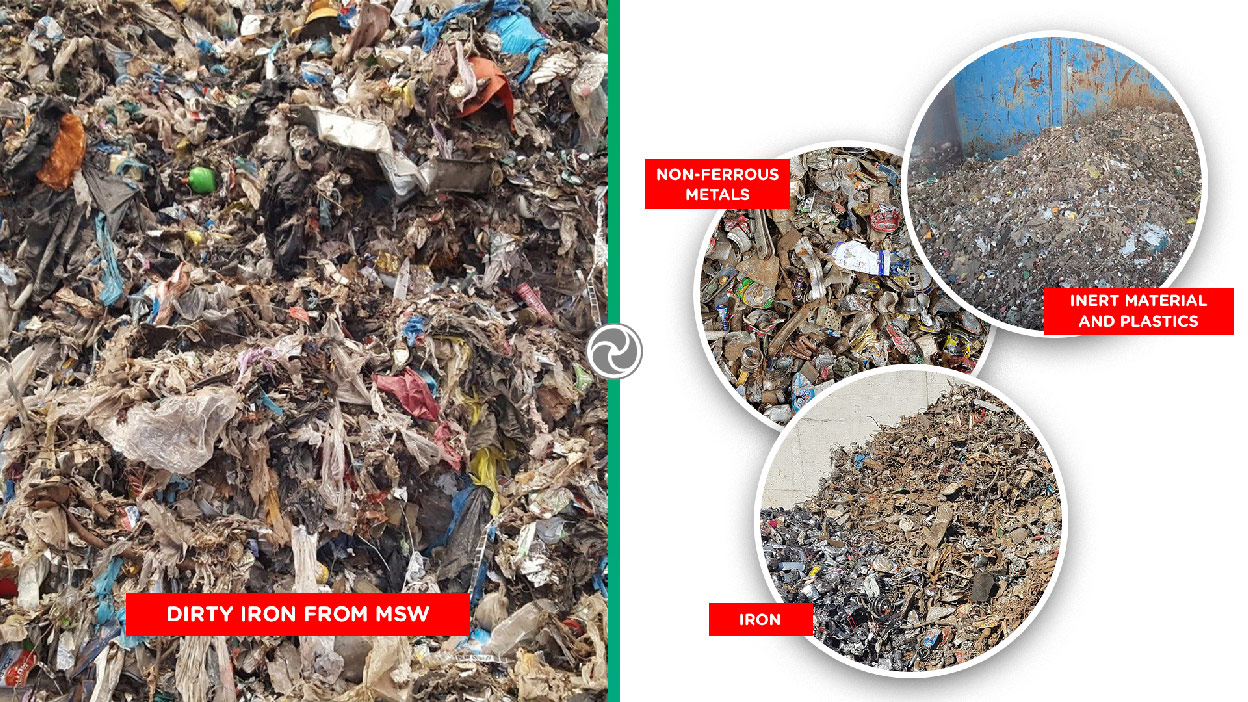

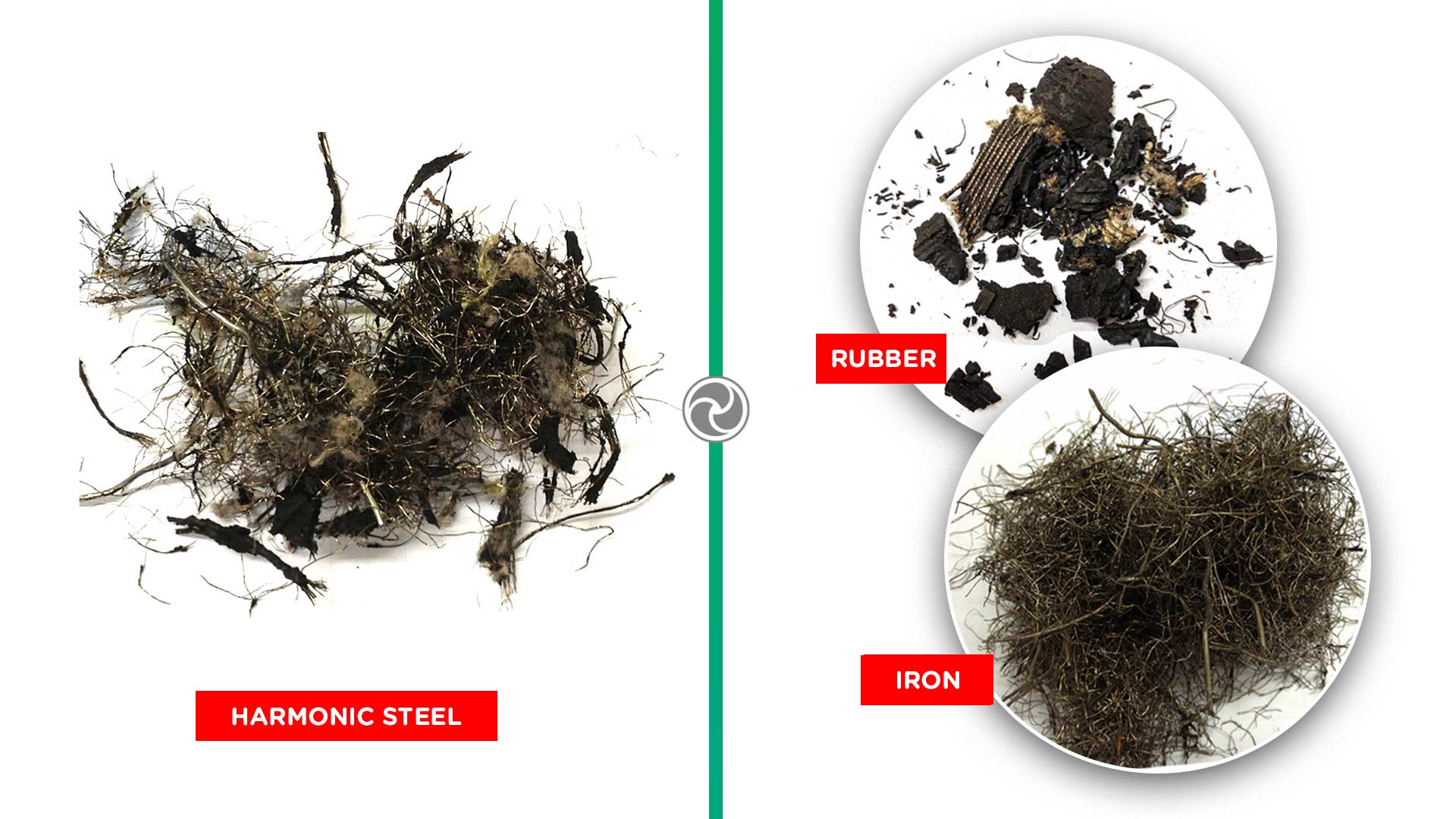

ITR Recycling System’s SZZ air separator is specifically designed to separate lightweight materials—such as plastic, nylon, and rubber—from heavier fractions, including metals and heavy-duty plastics, using an innovative zig-zag airflow system developed in-house by ITR Recycling Systems. This cutting-edge design ensures precise separation and enhanced process control, maximizing both product purity and operational efficiency.

Available in a range of capacities to suit different production needs, the SZZ air separator can function as a standalone unit or be seamlessly integrated into existing processing lines. It is particularly effective for separating ferrous and non-ferrous metals from municipal solid waste (MSW). An independent electrical panel allows for streamlined control and monitoring, ensuring consistent performance and easy operation in various recycling and waste management scenarios.

Ballistic separators | ITR BSP

Air Separators | ITR AS

ITR Recycling Systems – Air Separators are purpose-built for separating lightweight materials from heavier fractions through a combination of air blowing and extraction. This highly adaptable technology is suitable for diverse recycling and waste management applications, including municipal solid waste (MSW) and construction and demolition (C&D) debris.

Operating on the principle of controlled airflow, these separators lift and direct lighter components—such as plastics and paper—away from heavier materials like metals and glass. Adjustable deflectors and airspeed controls allow operators to fine-tune the process for optimal performance across various material types and densities. By efficiently separating and reducing contamination, these Air Separators enhance downstream processes, improve resource recovery rates, and can be seamlessly integrated into existing sorting lines or used as standalone units.

Magnetic Separation Systems | ITR SPA